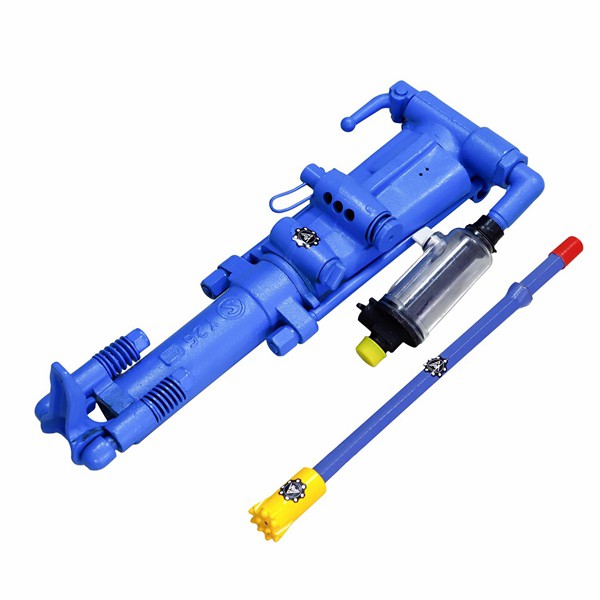

Manufacturer's price Pneumatic Rock Hammer Rock Drill Jack Hammer Hand Rock Drill for sale

Product description

Pneumatic rock drills are widely used in fields such as mining, tunnel excavation, building demolition, and foundation engineering. In mining operations, pneumatic rock drills are used to drill blast holes in hard rocks for blasting operations. In tunnel excavation, pneumatic rock drills are used to drill tunnel contours in rock or concrete for subsequent construction work. In building demolition and foundation engineering, pneumatic rock drills are used to break and demolish concrete structures, providing convenience for construction.

The working principle of pneumatic rock drills is relatively simple and efficient. It utilizes the high-pressure airflow generated by the air compressor to be transported through pipelines to the cylinders inside the rock drill. When compressed air enters the cylinder, it pushes the piston forward, which in turn drives the chisel head to impact and break rocks or concrete. This high-frequency impact allows rock or concrete materials to be quickly crushed and chiseled open, thereby achieving the purpose of drilling or crushing.

Pneumatic rock drills can be classified into various types based on their structure and usage. According to the classification of propulsion methods, there are mainly handheld rock drills, pneumatic leg rock drills, telescopic upward rock drills, and guide rail rock drills. These different types of rock drills are suitable for different work scenarios and job requirements. As an important construction tool in the fields of mining and construction, pneumatic rock drills play an irreplaceable role in engineering construction. In the future, with the continuous development of technology and the continuous expansion of innovative application fields, pneumatic rock drills will usher in a broader development prospect.

In the fields of mining, building demolition, and foundation engineering, pneumatic rock drills play a crucial role as an important construction tool. It has won the favor of engineers and operators due to its high efficiency, safety, and reliability. This article will provide a detailed introduction to the working principle, classification, characteristics, and future development trends of pneumatic rock drills.

Recommended products