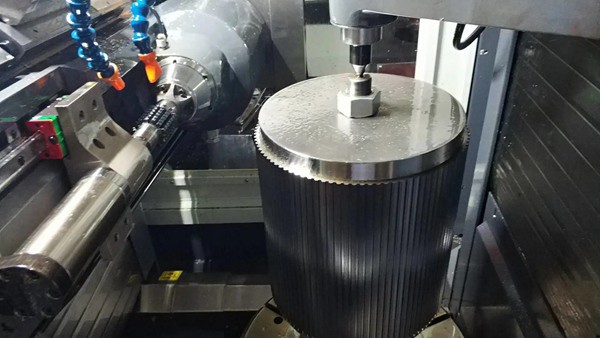

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Product description

Gear hobbing machines can process gears of various shapes and specifications, including straight teeth, helical teeth, bevel teeth, etc. This wide adaptability enables gear hobbing machines to meet the gear processing needs of different industries. Modern gear hobbing machines adopt advanced CNC technology, making operation more convenient and intuitive. Operators only need to input the corresponding processing parameters to achieve automated processing.

The gear hobbing machine adopts the generation method to process gears, which can accurately control the tooth shape and modulus of the gears, ensuring the accuracy of the gears. This high-precision machining method helps to improve the transmission efficiency and service life of gears.

The operation process of a gear hobbing machine mainly includes steps such as machine preparation, workpiece clamping, adjusting machining parameters, and starting machining. Firstly, it is necessary to place the gear hobbing machine on a stable foundation and secure it, and install the corresponding gear hobbing tools and fixtures. Then, inspect and adjust the gear hobbing machine to ensure that all parts are working properly. Next, place the gear to be machined into the workpiece fixture and clamp it, and set the machining parameters according to the shape and machining requirements of the gear. Finally, start the gear hobbing machine and start processing. If the processing quality does not meet the requirements, adjustments and corrections should be made in a timely manner.

Gear hobbing machines have a high degree of automation and can achieve continuous and high-speed machining of gears. Compared to traditional cutting methods, gear hobbing machines have higher production efficiency, which helps to reduce production costs. The gear hobbing machine adopts rolling cutting method, which generates less cutting heat, so it will not produce heat treatment effects such as quenching and annealing on the gear surface. This can ensure the surface quality of the gears and prevent the occurrence of cracks and fatigue.

Recommended products