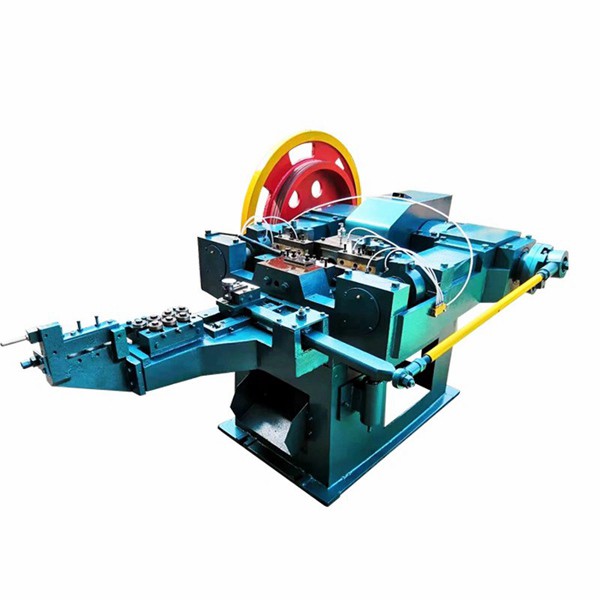

Wholesale Durable Auto Steel Wire Nail Making Professional Manufacturing CNC Machine

Product description

The working principle of a high-speed nail making machine mainly includes steps such as wire feeding, cutting, welding, positioning, forming, and removal. The steel wire is fed into the machine through the feeding system, and after precise cutting and welding, the steel wire is positioned and shaped into the required nail shape. Finally, it is automatically removed by the hook head to complete the production of the nail. The high-speed nail making machine is suitable for producing various types of nails, such as roll nails, paper row nails, core pulling rivets, large and small cap nails, etc., and has strong adaptability.

High speed nail making machine, also known as high-speed nail making equipment or high-speed nail machine, is an efficient machinery specially designed for manufacturing various specifications and types of nails. It can quickly complete the feeding, cutting, welding, positioning, forming and other processes of steel wires through automated and continuous production methods, thereby greatly improving the production efficiency of nail making. The main characteristic of high-speed nail making machines is their high production capacity. For example, a certain model of high-speed nail making machine can achieve a speed of producing 760 nails per minute, or even higher.

With the continuous progress of technology, nail making machines are also constantly being updated and replaced. In the future, nail making machines will develop towards greater intelligence and automation to meet the production needs of higher efficiency and precision. Meanwhile, with the increasing awareness of environmental protection, nail making machines will also pay more attention to energy conservation and emission reduction, reducing their impact on the environment.

The nail making machine mainly consists of a feeding system, a stamping system, a cutting system, and a control system. Its working principle is to feed raw materials into the stamping area through a feeding system, undergo a series of precision stamping and cutting operations, and finally produce nails that meet the requirements. Throughout the process, the control system plays a crucial role in ensuring stable and efficient production of the machine according to preset parameters.

Recommended products