China Manufacturer Scotch Gum Tape Slitter Rewinder Machine

Product description

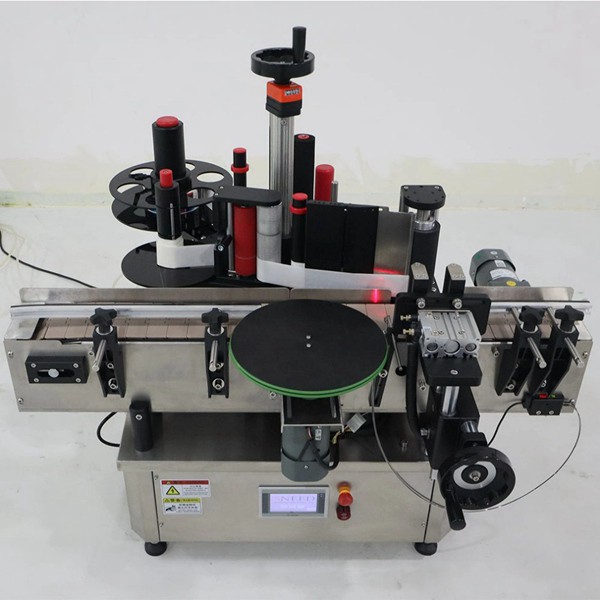

The chewing gum labeling machine has a highly automated feature, which can achieve functions such as automatic label picking, automatic label delivery, and automatic pasting. Greatly reduces manual operations and improves the automation level of the production line. The chewing gum labeling machine is equipped with an intelligent monitoring system, which can monitor the labeling process in real time and automatically adjust parameters. Once an abnormal situation is detected, the system will automatically alarm and shut down to ensure the safety and stability of the production line.

The chewing gum labeling machine adopts advanced control system and precise mechanical transmission to ensure efficient and stable labeling process. Meanwhile, through optimized algorithms and precise design, precise positioning and fast pasting of labels have been achieved. The chewing gum labeling machine can be flexibly adjusted according to different chewing gum packaging and labeling requirements. Whether it's packaging of different shapes or labels of different sizes, it can be easily handled.

The self-adhesive labeling machine uses self-adhesive labels for labeling, which have the characteristics of strong adhesion, water and oil resistance, and easy tearing off. Widely used in industries such as food and medicine. Suitable for labeling needs on large-scale and high-speed production lines. It has the characteristics of fast labeling speed, good stability, and high accuracy. The labeling machine can automatically complete the steps of label retrieval, positioning, and pasting, greatly reducing manual operation time and improving production efficiency.

Suitable for labeling flat objects, such as bottles, boxes, etc. It has the characteristics of simple structure, convenient operation, and fast labeling speed. Specially used for labeling round bottle shaped objects, such as beverage bottles, cosmetic bottles, etc. By using a rotating labeling mechanism, ensure that the label is evenly and smoothly pasted on the round bottle. As an important part of automated production lines, labeling machines have brought revolutionary changes to various industries due to their high efficiency, precision, and reliability.

The working principle of the labeling machine mainly relies on mechanical transmission, control system, and label conveying system. Firstly, set the position, size, quantity and other parameters of the labels through the control system; Then, the mechanical transmission system drives the label conveyor belt to transport the label to the designated position; Finally, the label is pasted onto the product through a pasting mechanism. Throughout the entire process, the control system monitors the labeling effect in real time to ensure the accuracy and consistency of the labels.

Recommended products