Automatic Spray Head Bottle Liquid Filling Machine with CE and ISO

Product description

Application field:

Food industry: filling of beverages, jams, seasonings, etc.

Beverage industry: filling of various bottled and canned beverages.

Chemical industry: filling of paints, coatings, inks, etc.

Cosmetic industry: filling of products such as shampoo, shower gel, skincare products, etc.

The liquid filling machine adopts automatic control, which can achieve high-speed and continuous filling operations, greatly improving production efficiency. By using high-precision measuring devices and control systems, we ensure that the amount filled each time meets the preset standards, reducing waste and errors. It is suitable for liquids of various viscosity and concentration, including oil, water, lotion, etc. Adopting advanced materials and processes for manufacturing, ensuring the stability and reliability of the equipment during long-term operation. The equipment is easy to operate and maintain, reducing operating and maintenance costs.

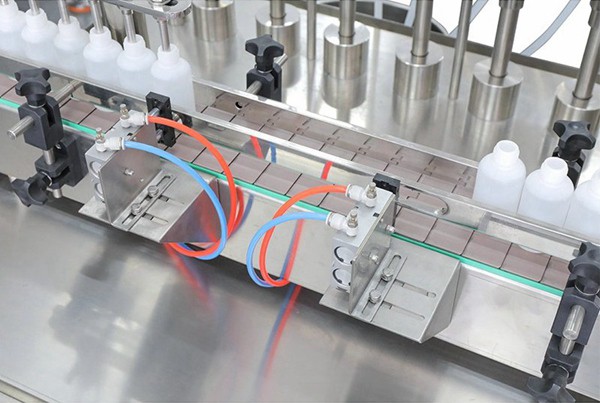

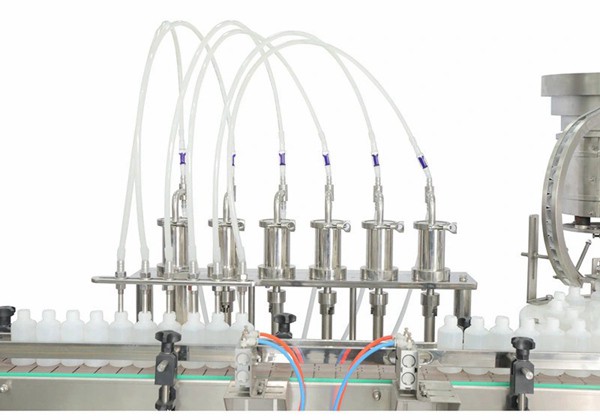

The working principle of liquid filling machines is relatively simple, but in practical operation, high precision and stability are required. Its main components include a storage tank, a conveying pump, a metering device, a filling head, and a control system. Firstly, the liquid is extracted from the storage tank through a transfer pump, filtered and regulated before entering the metering device. The measuring device accurately measures the preset filling amount and then injects the liquid into the container through the filling head. Throughout the process, the control system is responsible for monitoring and adjusting each link to ensure the accuracy and stability of filling.

Some capping and filling machines, such as fully automatic capping machines, have a capping yield of over 99%, which reflects the advantages of capping accuracy and efficiency of capping and filling machines. In addition, some capping filling machines also have feeding valves composed of fast and slow filling, which can improve filling speed while ensuring filling accuracy, and the measurement error can even be less than 10 grams per barrel.

The capping and filling machine can automatically seal according to the size and shape of the bottle cap, reducing manual operation errors and labor intensity. Some capping and filling machines also have automatic detection functions to ensure the sealing degree and correctness of bottle caps, reducing losses caused by poor sealing. The equipment can automatically transport filled liquid products, as well as automatically transport and seal bottle caps, improving the overall production capacity and stability of the production line.

Recommended products