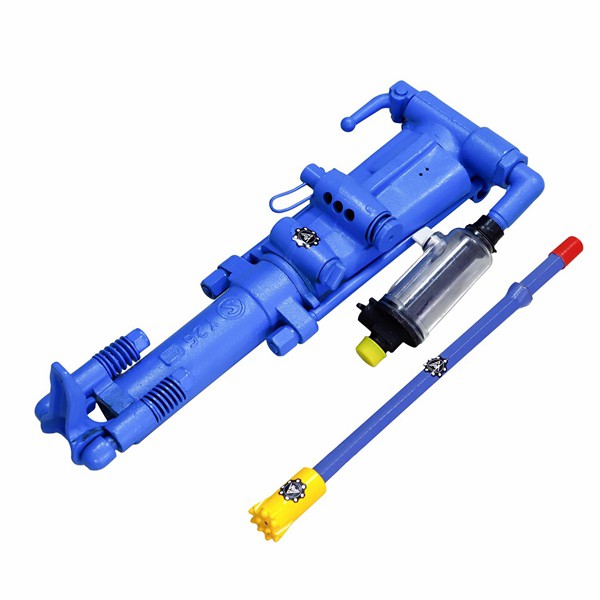

Portable Pneumatic Jack Hammer Air Leg Hand Held Rock Drill for sale

Product description

The working principle of pneumatic rock drills is relatively simple and efficient. It utilizes the high-pressure airflow generated by the air compressor to be transported through pipelines to the cylinders inside the rock drill. When compressed air enters the cylinder, it pushes the piston forward, which in turn drives the chisel head to impact and break rocks or concrete. This high-frequency impact allows rock or concrete materials to be quickly crushed and chiseled open, thereby achieving the purpose of drilling or crushing.

In the future, pneumatic rock drills will pay more attention to the development of intelligence, high efficiency, environmental protection, and energy conservation. For example, introducing intelligent technology to achieve functions such as remote control, automatic positioning, and fault diagnosis; Adopting more efficient engines to reduce energy consumption and emissions; Developing new types of drill bits and tools to improve drilling quality and efficiency. In addition, with the increasing awareness of environmental protection and the implementation of environmental policies, the application of pneumatic rock drills in areas such as environmental governance and soil remediation will gradually increase.

Pneumatic rock drills have many significant characteristics. Firstly, it uses compressed air as the power source, with a simple structure, safety, reliability, and easy maintenance. Secondly, pneumatic rock drills have high drilling efficiency and impact force, and can quickly crush materials such as rocks and concrete. In addition, pneumatic rock drills also have good flexibility and adaptability, which can adapt to different working environments and operational needs.

Installed on the pneumatic leg, utilizing the support and propulsion effects of the pneumatic leg to reduce the operator's labor intensity. Rock drilling has high efficiency and can drill deep blast holes, widely used in mining and construction fields. Specially used for drilling upward boreholes, mainly for rock drilling operations in mining areas and courtyards. Its telescopic design allows the rock drill to adapt to drilling needs at different angles.

In the fields of mining, building demolition, and foundation engineering, pneumatic rock drills play a crucial role as an important construction tool. It has won the favor of engineers and operators due to its high efficiency, safety, and reliability. This article will provide a detailed introduction to the working principle, classification, characteristics, and future development trends of pneumatic rock drills.

Recommended products