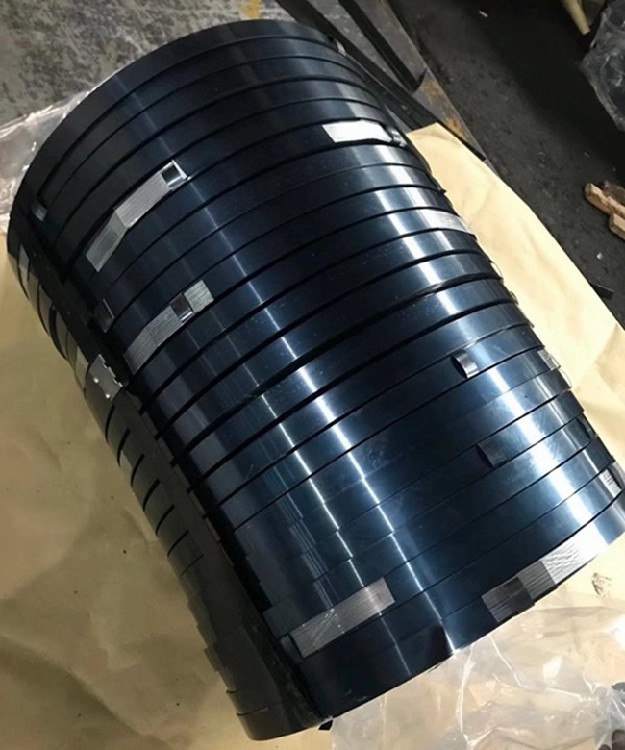

Factory Direct Sales Blue /Black Painted /Galvanized Packing Steel Strapping for Industry Packaging

Product description

When using steel ties, appropriate specifications and materials should be selected according to actual needs to ensure fixation effect and service life. Avoid using steel ties in situations beyond their load-bearing capacity to prevent breakage or damage. When using steel ties in special environments (such as high temperature, humidity, etc.), products with corresponding characteristics should be selected to ensure safety and reliability.

Steel zip ties have excellent tensile strength and can withstand large tensile forces without being easily broken. Stainless steel zip ties have good corrosion resistance and can be used for a long time in humid and highly corrosive environments without damage. Some special materials of steel ties also have high-temperature resistance characteristics, suitable for fixing and bundling work in high-temperature environments. Steel ties are easy and convenient to operate, and can quickly and effectively fix and bind items.

The commonly used packaging steel strip materials in modern packaging industry include cold-rolled steel strip, hot-dip galvanized steel strip, and tinplate. Among them, cold rolled steel strips can further improve their strength and comprehensive performance through processes such as temperature control, rolling control, and low-temperature annealing. At the same time, adding a small amount of microalloying elements such as niobium to the steel can refine the grain size, strengthen precipitation, and further improve the performance of the steel strip.

Cold rolled low-carbon steel strip is selected as the raw material, which undergoes processes such as oil removal, cleaning, and surface treatment to ensure the quality of the raw material. Heat the cleaned raw materials in the heating furnace, and then send them to the rolling mill for rolling, forming the required width and thickness through multiple rounds of rolling. Remove the oxide scale and minor defects on the surface of the steel strip to increase its corrosion resistance and surface smoothness. Eliminate residual stress and intergranular defects during the rolling process, and improve the machinability of the steel strip. Including processes such as cutting plates and punching holes, cutting the steel strip into appropriate sizes and punching holes in the required positions. Roll the processed steel strip into coils and tightly package them for storage and transportation.

Recommended products