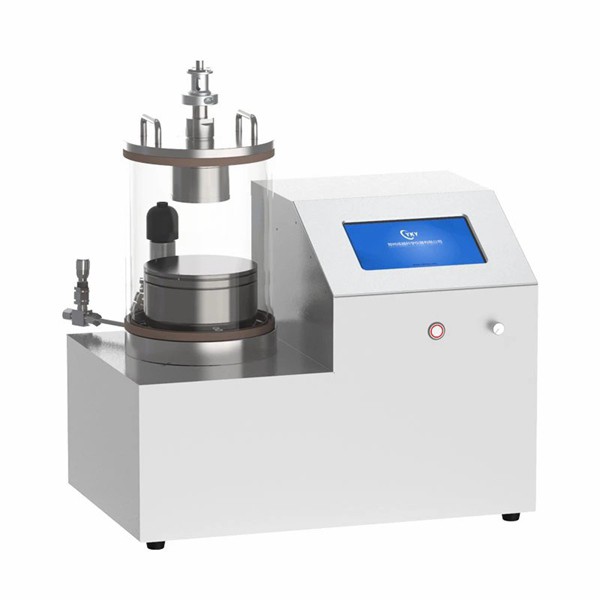

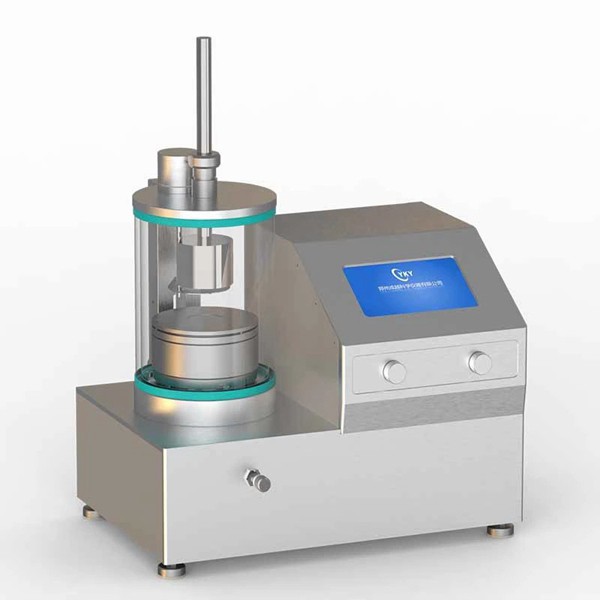

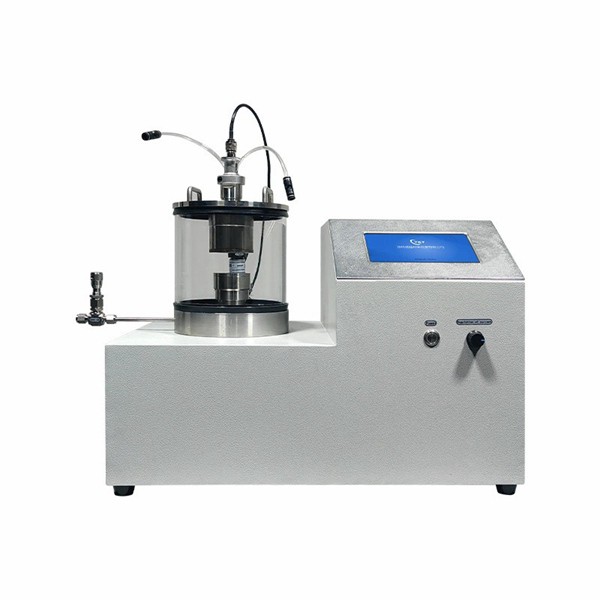

China Supplier High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process

Product description

Coating machines have been widely used in industries such as semiconductors, optoelectronics, healthcare, and aviation. In the field of chemical drugs, coating technology is used to ensure the purity and stability of materials; In the field of electronic optics, the manufacturing of high-precision components and devices cannot be separated from coating technology; In the fields of machinery and automotive manufacturing, coating technology is used for the treatment of metal surfaces; In the field of medical devices and food packaging, coating technology provides corrosion resistance and wear resistance.

The basic components include a vacuum system, sedimentation chamber, power supply, and control system. The vacuum system is used to create a vacuum, and the deposition chamber is the main area for depositing thin films. The power supply controls parameters such as material deposition speed and temperature, and the control system ensures that the deposition thickness, uniformity, and quality of the thin film meet the requirements. According to different processes, requirements, and applications, coating machines can be divided into various types, such as physical vapor coating machines, chemical vapor coating machines, ion coating machines, magnetron coating machines, sputtering coating machines, etc.

Sputtering coating machines are widely used in fields such as optics, electronics, aerospace, medical devices, etc., mainly for preparing functional thin film materials. Sputtering coating machines are widely used in the coating manufacturing of optical equipment such as glasses, optical lenses, and photography lenses, to increase optical performance such as anti reflection, anti reflection, and reflectivity.

Sputtering coating machine is a surface treatment equipment based on the phenomenon of sputtering. Sputtering refers to the process in which atoms or molecules on the surface of a solid target material detach and deposit onto the substrate surface under the bombardment of high-energy particles (such as ions, electrons, etc.). The sputtering coating machine uses inert gas (such as argon) or oxygen as the working gas, and uses methods such as arc, ion beam, or magnetic field to heat and excite the surface atoms of the target material, causing them to detach and deposit on the substrate surface, forming the required functional thin film.

Recommended products