Competitive Price Sea Water Resistant Steel Sheet Piling Factory Price

Product description

The construction of steel sheet piles mainly includes identifying underground obstacles, leveling the site, determining the pile position, pressing the steel sheet piles, implementing drainage measures, excavating and installing supports (or anchoring), excavating to the bottom of the foundation pit and promptly carrying out foundation treatment, constructing the cushion layer and main structure, and gradually backfilling in a timely manner.

Steel sheet piles are widely used in docks, unloading yards, embankments, retaining walls, breakwaters, diversion embankments, shipyards, gates, etc. In emergency situations such as flood control, collapse prevention, and quicksand prevention, steel sheet piles can also quickly build temporary water and soil retaining structures, effectively responding to disasters.

Steel sheet piles are also widely used in municipal engineering, foundation pit support, road widening retaining walls, isolation facilities, load-bearing foundations, and other engineering projects. Its unique performance and wide range of applications have made steel sheet piles highly favored in the engineering industry.

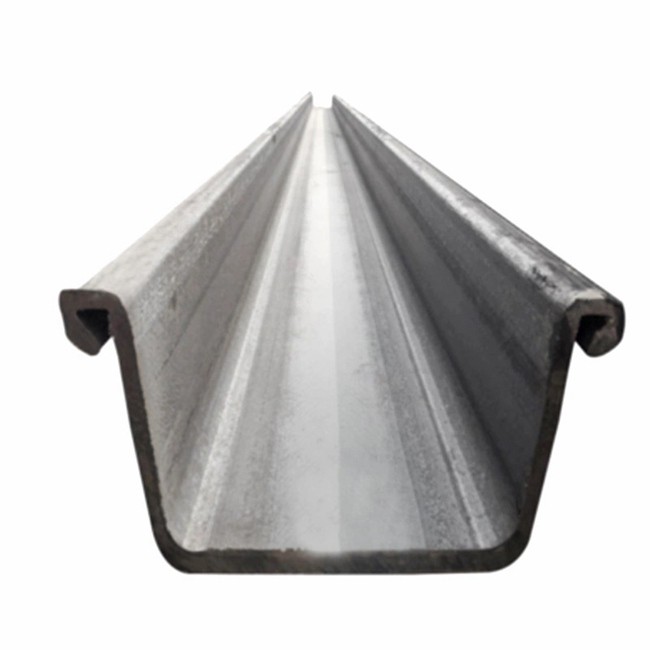

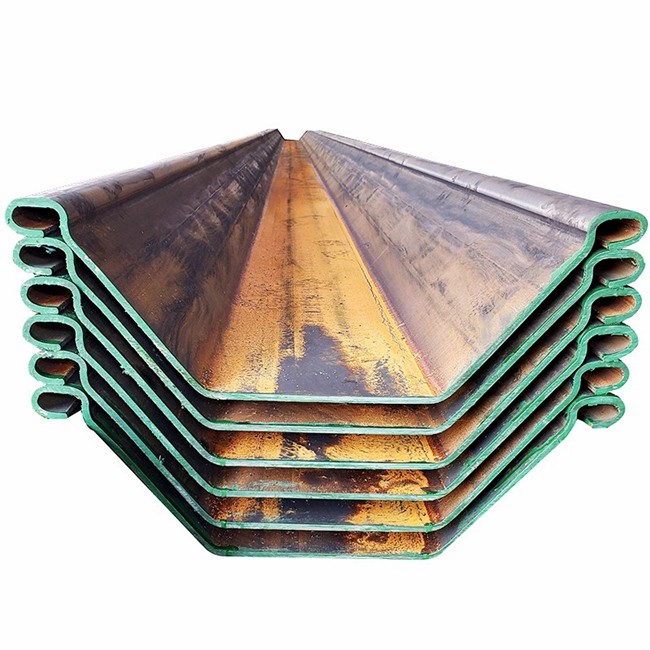

Steel sheet piles have high strength and can be easily driven into hard soil layers to form a stable support structure. The locking design of steel sheet piles gives them good waterproof performance and is suitable for various projects that require waterproofing. Steel sheet piles are factory finished products, which are easy to construct, have a short construction period, and reduce construction costs. The service life of steel sheet piles is over 50 years, and they can be reused multiple times, with high economic efficiency. The construction of steel sheet piles reduces the amount of soil and concrete used, effectively protecting land resources.

Steel sheet piles can be divided into various types according to their cross-sectional shapes, such as straight plate, groove, Z-shaped, U-shaped, H-shaped, etc. Among them, U-shaped steel sheet piles are the most widely used in China. Steel sheet piles can be divided into two types according to production technology: cold-formed steel sheet piles and hot-rolled steel sheet piles. Hot rolled steel sheet piles dominate the market due to their high strength and stable size. Cold formed steel sheet piles, on the other hand, are made of thinner sheets (commonly ranging in thickness from 8mm to 14mm) and processed by cold forming machines, which have the advantages of convenient production and customizable length.

Recommended products