Direct Factory Trapezoidal Profile Roofing Sheet Roll Forming Machine Ibr Making Roof Tile Machine

Product description

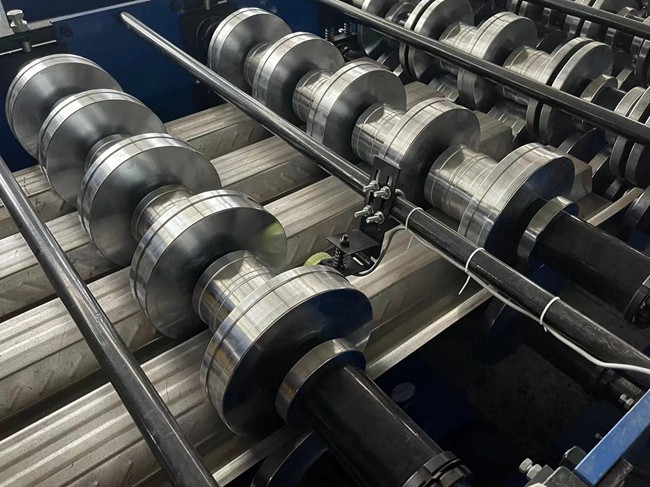

The metal tile forming machine usually adopts a three beam and four column structure, which has good strength and rigidity. Its main components, such as the upper beam, middle sliding beam, workbench, etc., are all welded with high-quality steel and undergo tempering treatment to eliminate internal stress. This structure not only ensures the stability and durability of the equipment, but also facilitates adjustment and maintenance.

With the rapid development of the construction industry and the continuous improvement of people's requirements for the performance of building materials, the market demand for metal tile forming machines continues to grow. At present, there are numerous manufacturers of metal tile forming machines emerging in the market, with a wide variety of product types and specifications. Meanwhile, with the continuous advancement and innovation of technology, the performance and efficiency of metal tile forming machines are also constantly improving, providing strong support for the development of the construction industry.

The cold tile forming machine usually consists of a large frame base, mechanical transmission system, hydraulic forming and cutting system, electrical control system, and feeding auxiliary system. These parts work together to ensure that the equipment can efficiently and stably complete processing tasks. Cold tile forming machine is an efficient, precise, and flexible metal processing equipment with broad application prospects in multiple industries.

Advantages and Characteristics

Efficiency: The cold tile forming machine can continuously and automatically complete processing tasks, greatly improving production efficiency.

High precision: Through precise roller and mold design, it can ensure that the processed products have extremely high dimensional and shape accuracy.

Flexibility: The equipment can adjust and replace molds according to different processing needs, thus adapting to processing tasks of various specifications and shapes.

Economy: Cold bending technology has lower energy consumption and less material waste compared to hot processing, therefore it has higher economic benefits.

Recommended products