China Supplier Non Adhesive Biaxial Glassfiber Geogrids Plastic Geogrid for Highway Subgrade Reinforcement

Product description

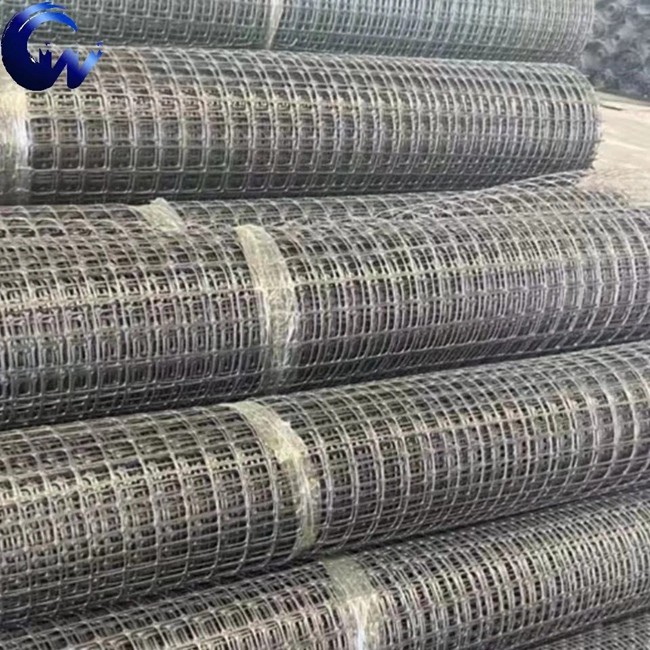

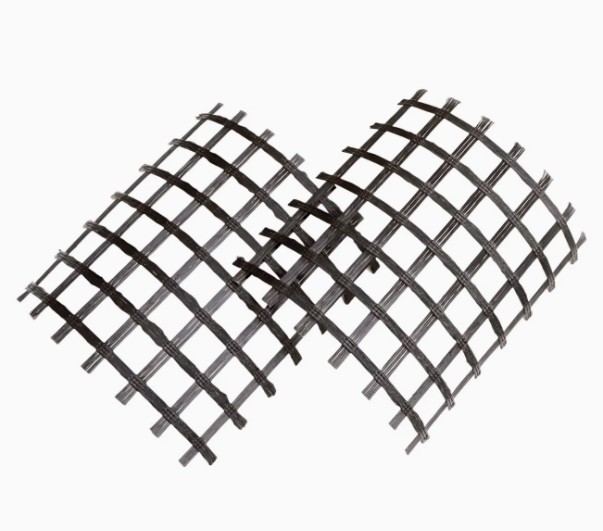

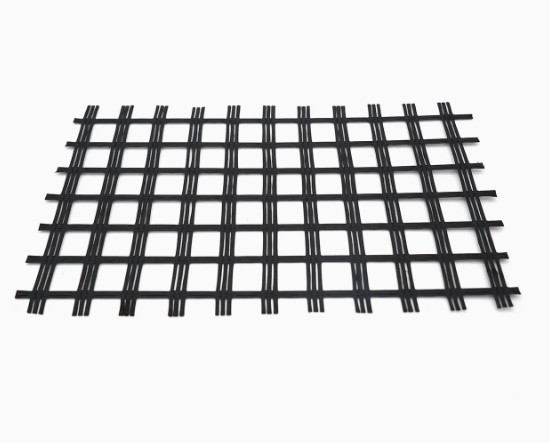

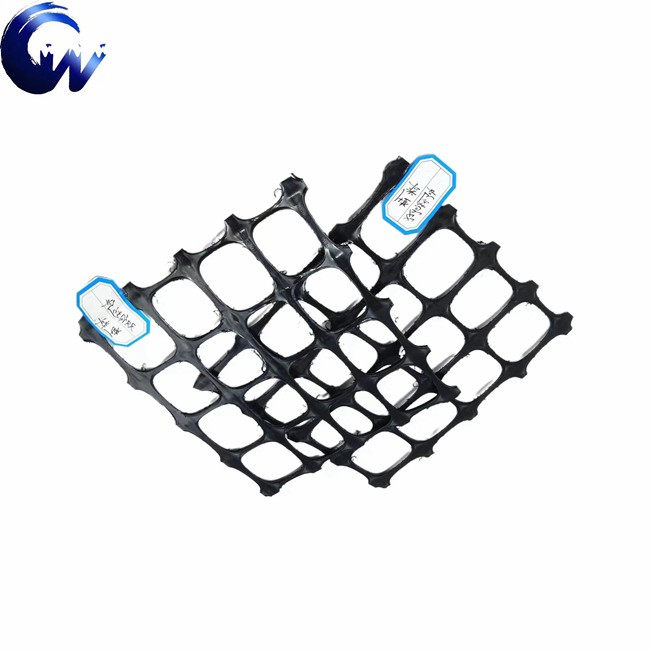

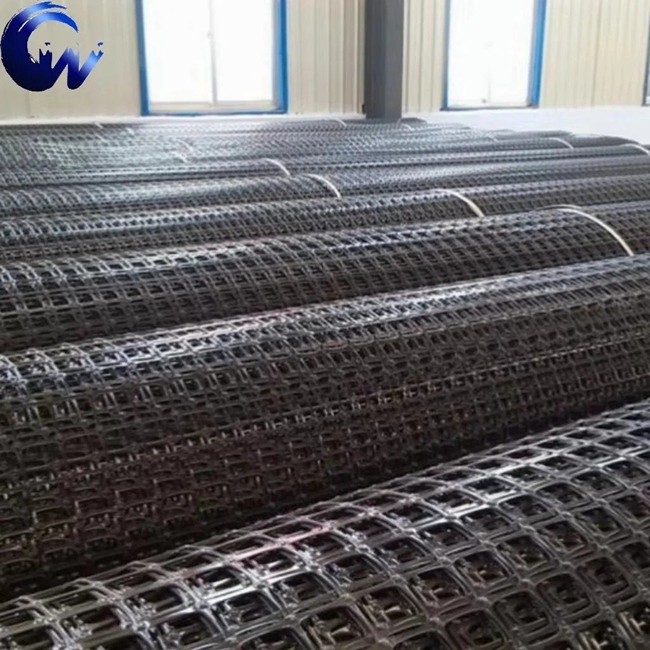

Biaxially stretched plastic geogrids are made from polypropylene (PP) or polyethylene (PE) as raw materials through plasticization, extrusion of sheets, punching, heating, longitudinal and transverse stretching. The effectiveness of using bidirectional geogrids is closely related to the treatment of the paved road surface. Before paving, it is necessary to thoroughly clean substances on the road surface that may affect the bonding strength between the geogrid and the underlying layer, such as grease, paint, sealing materials, water stains, dirt, etc., to ensure that the paving surface is clean and dry. Excavate the foundation bed, set up a sand cushion layer (with a height difference of no more than 10cm), roll it into a platform, lay a grid, and the longitudinal axis should be consistent with the main force direction. The longitudinal overlap should be 15-20cm, and the transverse overlap should be 10cm. Use plastic tape to tie and overlap. When laying the grid, fix it on the ground with U-shaped nails every 1.5-2m. The laid geogrid should be backfilled in a timely manner, and the number of layers should be determined according to technical requirements.

In the foundation treatment of buildings and structures, PP geogrids can improve the stress performance of the foundation, enhance the bearing capacity and stability of the foundation. The stretching and fixing effects of the grid can effectively prevent foundation settlement or uneven settlement. In slope engineering, PP geogrid can effectively prevent slope landslides and collapses, and protect the stability of the slope. Its high strength and corrosion resistance enable the grille to provide excellent protection in various harsh environments.

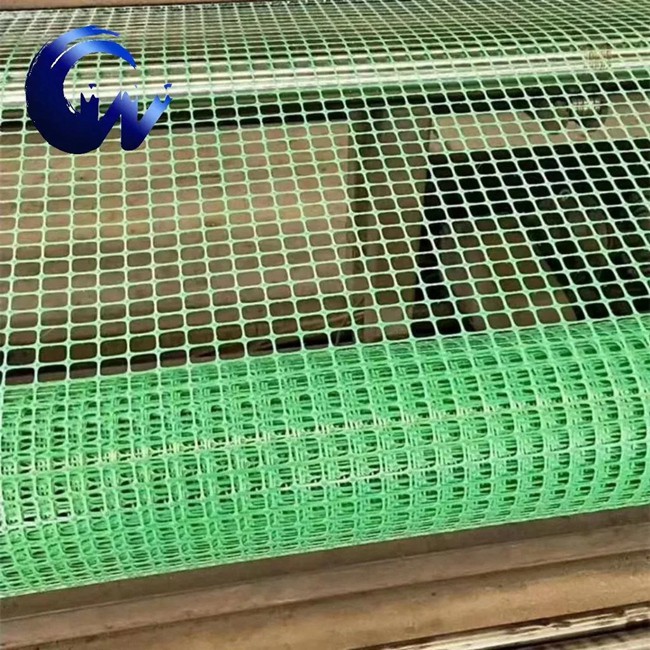

PP geogrid is lightweight, easy to cut and splice, greatly simplifying the construction process and improving engineering efficiency. Construction personnel can quickly lay and fix grilles, shortening the project cycle. PP material is non-toxic and harmless, environmentally friendly, and meets the needs of modern engineering for green building materials. The use of PP geogrids is not only beneficial for environmental protection, but also in line with the concept of sustainable development.

PP geogrid has excellent tensile strength and modulus, which can effectively disperse and transfer loads, significantly enhancing the overall stability of the soil. This characteristic enables it to withstand significant pressure and not easily deform in various engineering environments.

Polypropylene materials have excellent corrosion resistance and aging resistance, and can be used for a long time in various harsh environments without being easily damaged. This durability not only reduces the maintenance cost of the project, but also extends the service life of the project.

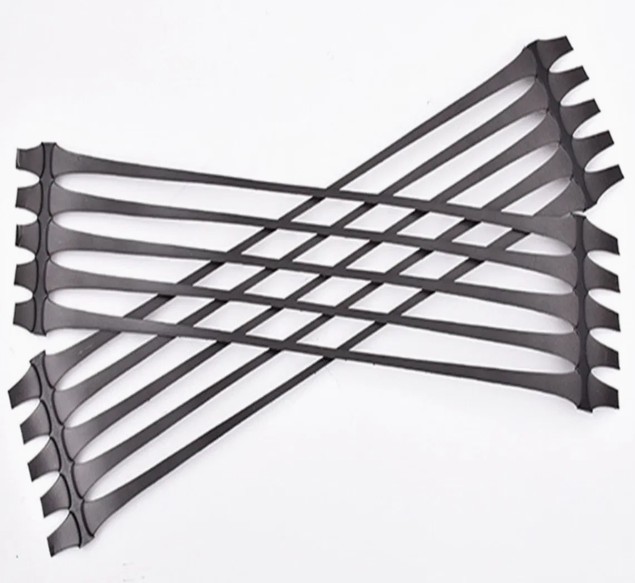

Recommended products