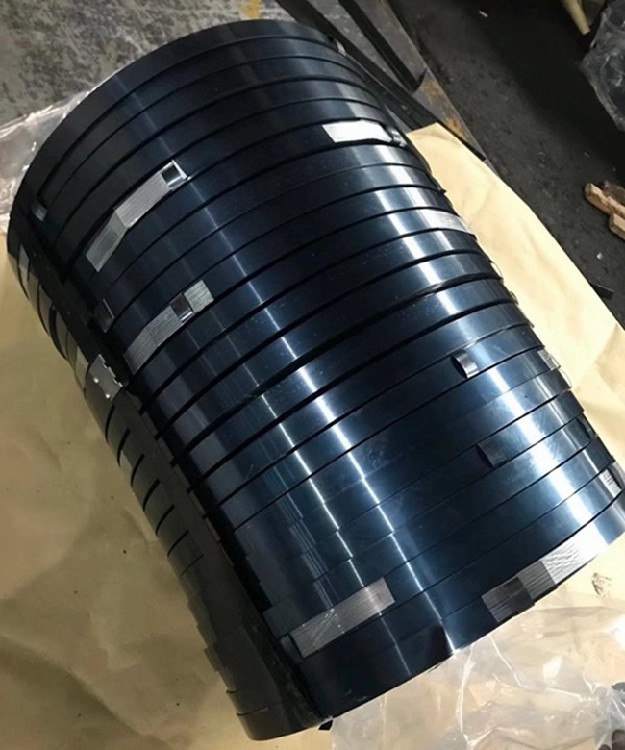

High Tensile Sales Steel Metal Strapping for Industry Packaging

Product description

Application scope

Power industry: used for cable bundling and fixation to ensure safe and reliable connection of cables.

Mechanical manufacturing: Fixing and restraining machinery and equipment, such as pipelines, wires, hydraulic pipelines, etc., to ensure the structural stability and safe operation of the machinery and equipment.

Petrochemical: Fix and maintain petroleum pipelines, chemical equipment, and containers to prevent oil leakage or accidents caused by vibration, temperature changes, or corrosion.

Aerospace: Used in the manufacturing and maintenance processes of aircraft and spacecraft to fix electrical wires, pipelines, instruments, and equipment.

Transportation: Fix and protect traffic signal lights, road signs, cables, and other facilities to ensure the stability and normal operation of transportation facilities.

Steel zip ties have excellent tensile strength and can withstand large tensile forces without being easily broken. Stainless steel zip ties have good corrosion resistance and can be used for a long time in humid and highly corrosive environments without damage. Some special materials of steel ties also have high-temperature resistance characteristics, suitable for fixing and bundling work in high-temperature environments. Steel ties are easy and convenient to operate, and can quickly and effectively fix and bind items.

Steel zip ties are a powerful and widely used fixing and binding tool, playing an important role in various industries. Steel tie is a tying tool made of metal material, which has high strength and durability. It consists of a long and narrow metal strip (usually made of stainless steel or cold-rolled steel, etc.) and a metal buckle (or retaining ring) used to fix both ends. When using, wrap the metal strap around the item that needs to be fixed, and then tightly fix the two ends together through metal buckles.

The commonly used packaging steel strip materials in modern packaging industry include cold-rolled steel strip, hot-dip galvanized steel strip, and tinplate. Among them, cold rolled steel strips can further improve their strength and comprehensive performance through processes such as temperature control, rolling control, and low-temperature annealing. At the same time, adding a small amount of microalloying elements such as niobium to the steel can refine the grain size, strengthen precipitation, and further improve the performance of the steel strip.

Recommended products