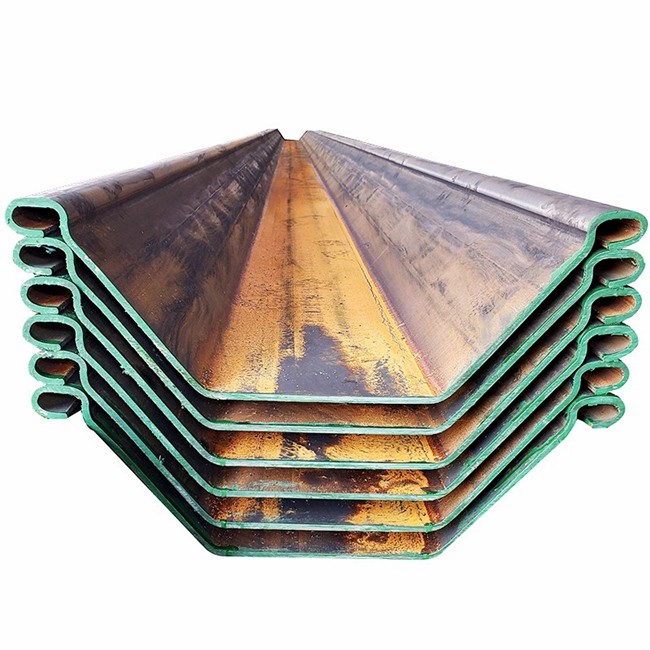

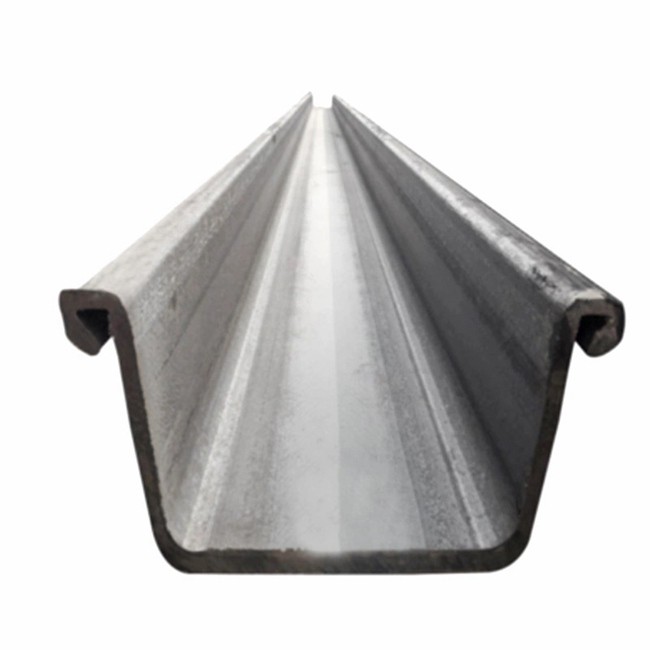

Competitive Price U Type Steel Sheet Pile Picket Sheet Piling for Cofferdam Soil Retaining

Product description

The construction of U-shaped steel sheet piles is relatively simple and does not require a large amount of formwork and concrete materials, reducing the construction process and complexity.

U-shaped steel sheet piles can be standardized in production, and their size and shape can be adjusted according to actual needs. They are also easy to install and disassemble during the construction process, greatly shortening the construction period.

The construction of groove shaped steel sheet piles mainly includes identifying underground obstacles, leveling the site, determining the pile position, pressing the steel sheet piles, implementing drainage measures, excavating and installing supports (or anchoring), excavating to the bottom of the foundation pit and promptly treating the foundation, constructing the cushion layer and main structure, and backfilling step by step in a timely manner. During the construction process, attention should be paid to the waterproofing of the joints to prevent soil erosion at the joints, which can cause geological collapse and instability. At the same time, it is necessary to ensure that the foundation pit itself has a certain degree of stability to prevent stability and strength damage such as overall, skirting, uplift, piping, and sand flow.

As an excellent foundation support material, groove shaped steel sheet piles are widely used in fields such as natural gas, oil, ports, docks, airports, and urban construction. In construction engineering, groove shaped steel sheet piles are mainly used for foundation support of various types of land and underground buildings, retaining walls, water tanks, precipitation outlets, and other foundation projects. In addition, it is also used in multiple fields such as hydraulic engineering, transportation route buildings, waterway maintenance, civil engineering, and hydraulic engineering buildings.

The construction of steel sheet piles mainly includes identifying underground obstacles, leveling the site, determining the pile position, pressing the steel sheet piles, implementing drainage measures, excavating and installing supports (or anchoring), excavating to the bottom of the foundation pit and promptly carrying out foundation treatment, constructing the cushion layer and main structure, and gradually backfilling in a timely manner.

Steel sheet piles have high strength and can be easily driven into hard soil layers to form a stable support structure. The locking design of steel sheet piles gives them good waterproof performance and is suitable for various projects that require waterproofing. Steel sheet piles are factory finished products, which are easy to construct, have a short construction period, and reduce construction costs. The service life of steel sheet piles is over 50 years, and they can be reused multiple times, with high economic efficiency. The construction of steel sheet piles reduces the amount of soil and concrete used, effectively protecting land resources.

Recommended products