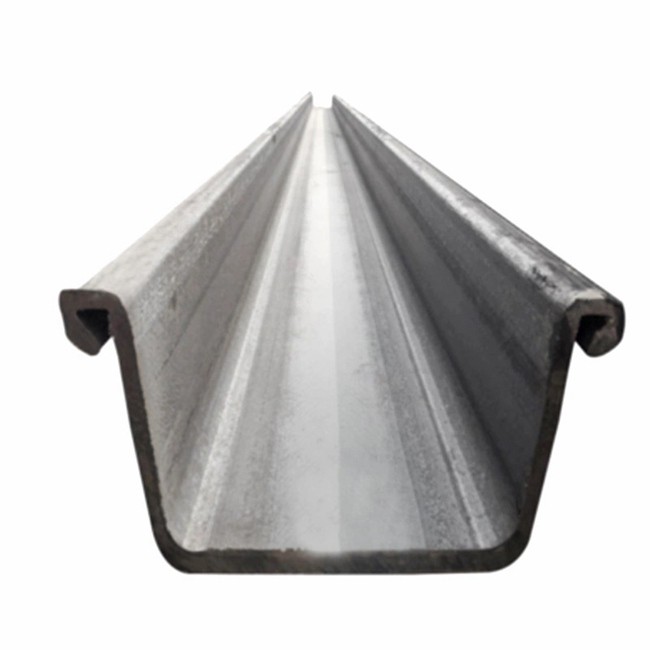

High Strength 400 Thick Corner Piles Steel Sheet Piling Factory Price

Product description

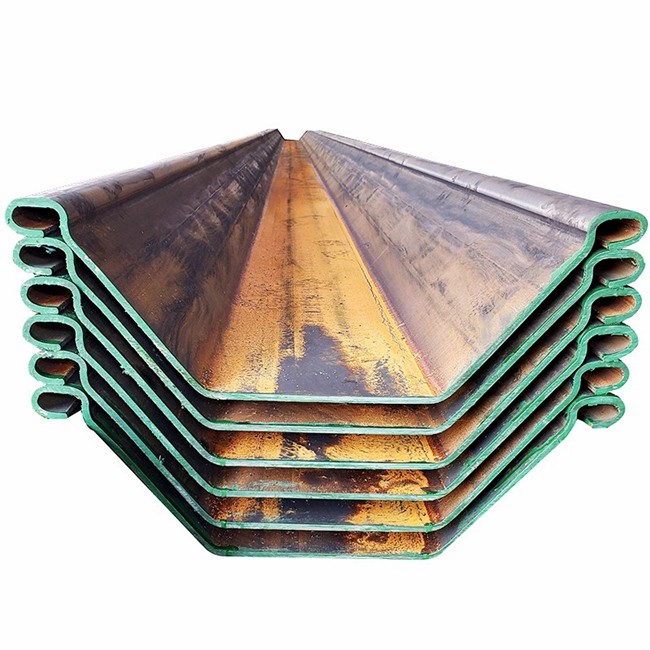

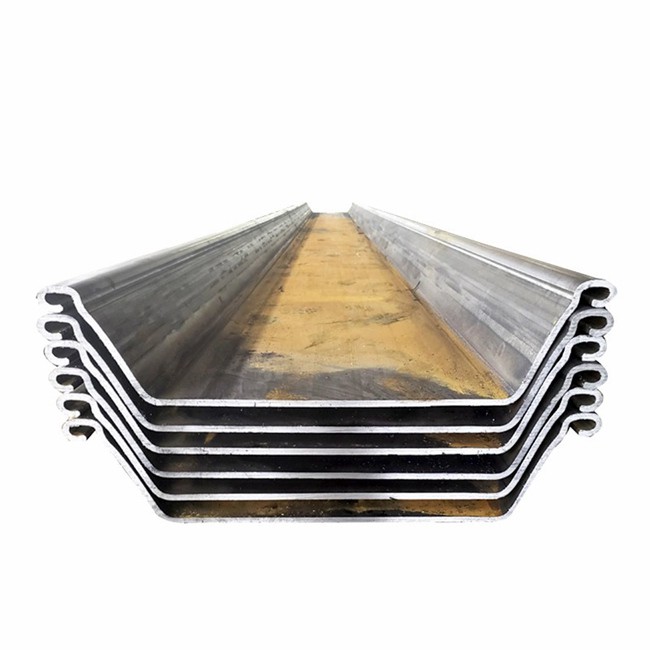

U-shaped steel sheet piles are made of steel and have high tensile, bending, and compressive strength, which can withstand large loads and seismic forces, ensuring the stability and safety of foundation engineering. The cross-sectional shape design of U-shaped steel sheet piles is reasonable, providing good stiffness and deformation resistance, especially suitable for engineering scenarios that require high support strength.

As an excellent foundation support material, groove shaped steel sheet piles are widely used in fields such as natural gas, oil, ports, docks, airports, and urban construction. In construction engineering, groove shaped steel sheet piles are mainly used for foundation support of various types of land and underground buildings, retaining walls, water tanks, precipitation outlets, and other foundation projects. In addition, it is also used in multiple fields such as hydraulic engineering, transportation route buildings, waterway maintenance, civil engineering, and hydraulic engineering buildings.

The geometric design on both sides of the groove shaped steel sheet pile is particularly prominent, and the steel plates can be overlapped or spliced, which is very convenient and fast. Similarly, disassembly is also very convenient. The slotted steel sheet pile can be disassembled and reused multiple times on the construction site, which not only saves construction costs but also reduces the impact on the environment. The groove type steel sheet pile has high production accuracy, beautiful and generous appearance, and is suitable for external and internal wall decoration, shaft support, drainage ditch, slope protection, underground continuous wall and other fields of general buildings and equipment.

The construction of steel sheet piles mainly includes identifying underground obstacles, leveling the site, determining the pile position, pressing the steel sheet piles, implementing drainage measures, excavating and installing supports (or anchoring), excavating to the bottom of the foundation pit and promptly carrying out foundation treatment, constructing the cushion layer and main structure, and gradually backfilling in a timely manner.

Recommended products