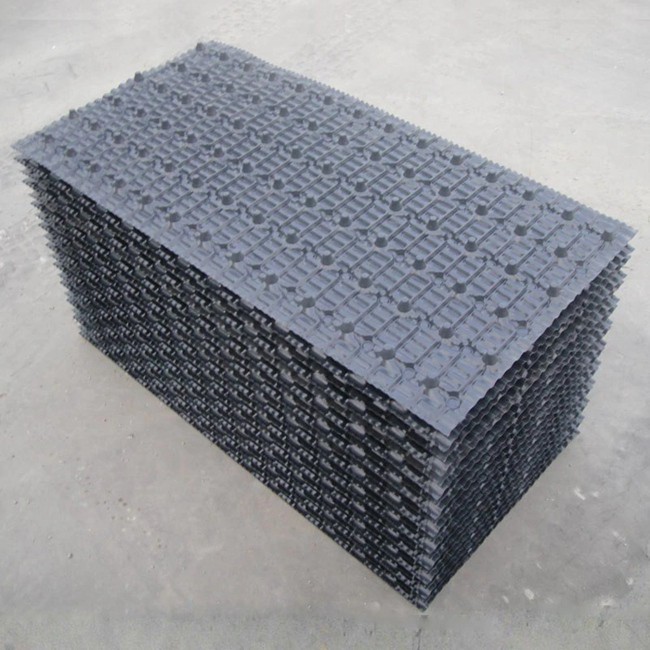

High Quality Cross Flow Width 730/750mm Cooling Tower PVC Filler

Product description

The manufacturing process of PVC filler mainly includes two steps: extrusion and molding. During the extrusion process, PVC particles are heated and extruded through a mold to form the desired filler shape. During the molding process, PVC particles are placed in molds with the desired shape and processed through heating and pressure to ultimately produce finished products. The precise control of these two steps ensures that the quality and performance of PVC fillers reach their optimal state.

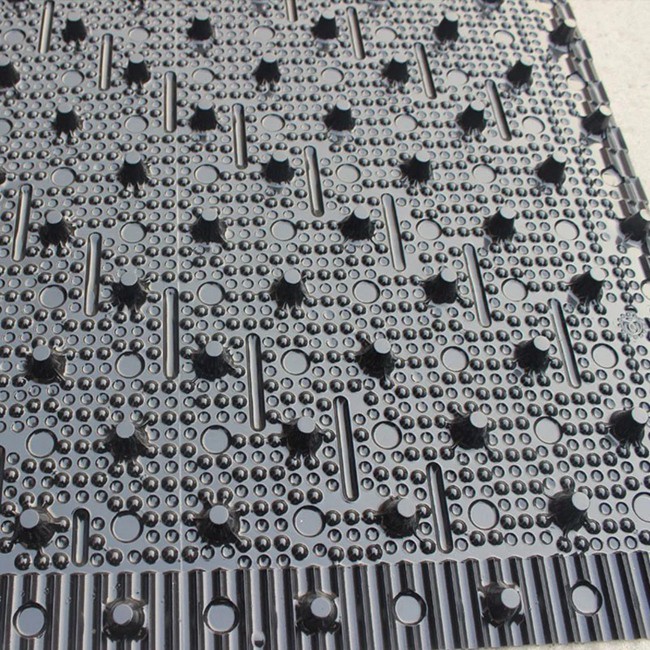

PVC fillers are known for their excellent chemical inertness, corrosion resistance, and wear resistance. It can maintain stable performance in various harsh environments and withstand long-term corrosion from chemical substances and impact from high-temperature fluids. In addition, PVC fillers also have excellent breathability and ventilation performance, thanks to their corrugated or hexagonal structure, which can significantly increase the breathable area of the filler bed and improve the efficiency of heat and mass exchange.

Recommended products