Direct Factory Wall Cladding Double Layer Steel Profile Zinc Metal Roofing Roof Glazed Tile Press

Product description

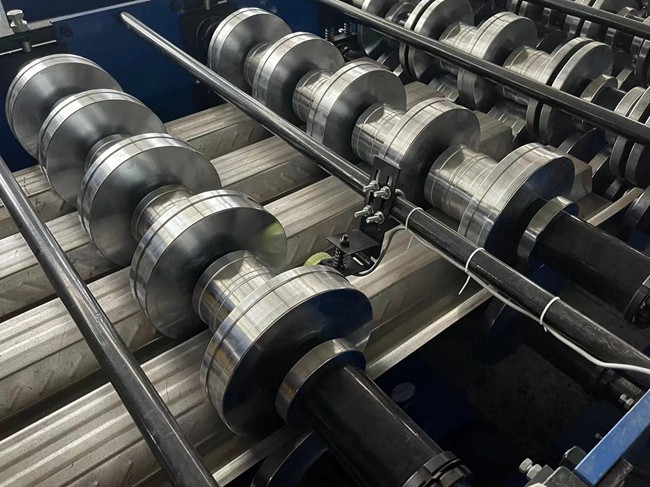

The metal tile forming machine mainly processes metal coils into various shapes and specifications of metal tiles through a series of precise mechanical actions. Firstly, place the metal coil into the material rack of the equipment. The material rack is adjusted according to the diameter and weight of the coil to ensure that the coil can smoothly and smoothly enter the forming part. After entering the forming section, the metal coil is pressed and bent by a series of rollers to form the desired tile shape. In this process, the precise design and adjustment of the rollers are crucial, as they determine the shape and quality of the tiles.

In order to enhance the wind resistance and appearance of the tiles, the forming part also includes a embossing device. By heating, cooling, and applying pressure, certain protrusions are formed on the surface of the tiles to improve overall performance. Finally, the formed tiles are cut to a predetermined length using hydraulic or mechanical cutting mechanisms, completing the entire production process.

The metal tile forming machine usually adopts a three beam and four column structure, which has good strength and rigidity. Its main components, such as the upper beam, middle sliding beam, workbench, etc., are all welded with high-quality steel and undergo tempering treatment to eliminate internal stress. This structure not only ensures the stability and durability of the equipment, but also facilitates adjustment and maintenance.

The metal tile copying machine has a wide range of applications in the metal tile processing industry, especially in high-end construction fields such as villas, museums, and tourist buildings that require high-precision and high-quality metal tiles. In addition, with the continuous advancement of technology and the expansion of application fields, metal tile copying machines are expected to play an important role in more fields.

Cold tile forming machines are widely used in various fields such as construction, transportation, home appliances, ships, and petrochemicals. In the construction industry, it can be used to produce components such as lightweight steel structures, steel buildings, roofs, wall panels, arch structures, safety doors, and window frames; In the manufacturing industry, it can be used to produce components such as wind turbine bucket frames, wire reels, and automotive chassis; In the shipbuilding industry, components such as hull structures and deck structures can be produced; In the petrochemical industry, it can be used to produce various pipelines and fittings.

Recommended products