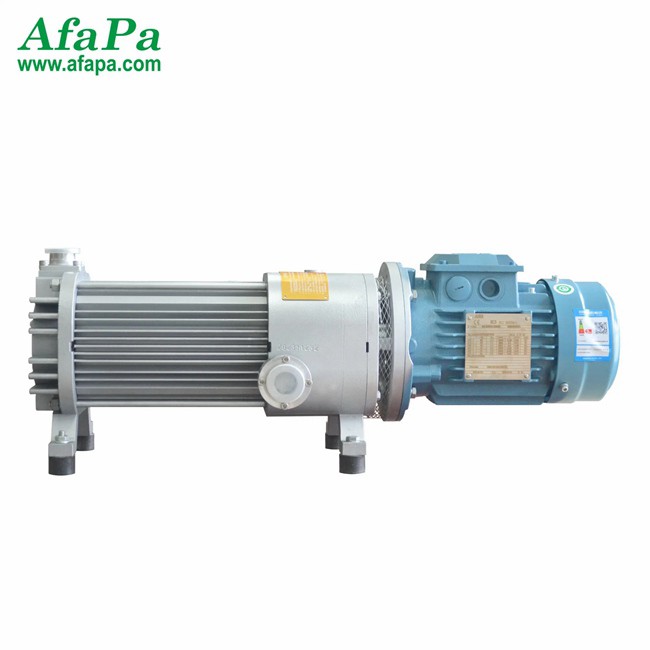

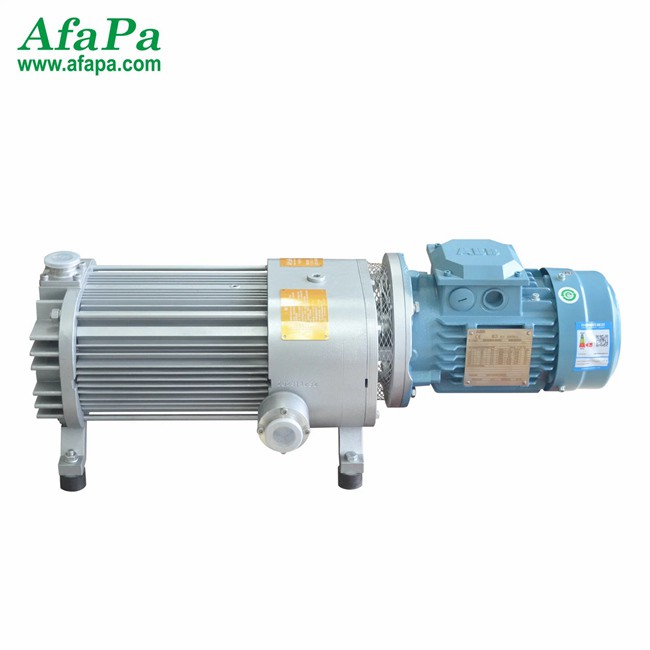

Factory Supplier Vacuum Evaporating Using Water Ring Vacuum Pump for Lab Vacuum Distillation

Product description

An oil-free vacuum pump is a type of pump that does not use lubricants in the chamber to generate vacuum or cool the pump. It achieves gas suction and vacuum creation through specific mechanical structures and working principles. Due to not using oil as a lubricant, it avoids oil pollution and oil vapor emissions, which meets environmental requirements. The oil-free design reduces the maintenance cost of the pump and extends its service life. Due to its unique performance and advantages, oil-free vacuum pumps are widely used in multiple fields.

advantage:

The structure is simple and compact, with the characteristic of isothermal compression.

There is no metal friction surface inside the pump, with minimal wear and gas can be continuously and stably pumped out.

Not sensitive to dust and water vapor in the extracted gas.

Vacuum pumps play an important role in food packaging and processing. Vacuum packaging can extend the shelf life of food, reduce oxygen exposure, and prevent food oxidation and spoilage. Meanwhile, in the food processing process, vacuum pumps are used for degassing and concentration, improving the quality and taste of food. In the semiconductor production process, a vacuum pump is used to provide an ultra-high vacuum environment to ensure the smooth progress of process operations such as thin film deposition and ion implantation. Vacuum pumps are used to simulate space environments and test the performance and reliability of aerospace devices.

Turbovacuum pumps use the rotation of the turbine to extract gas. A limited working chamber is formed between the turbine and the pump chamber. When the turbine rotates, the gas in the working chamber is discharged and new gas is sucked in. Molecular sieve adsorption vacuum pump utilizes the adsorption effect of molecular sieve on gas to achieve suction. Molecular sieves have a highly porous structure and can selectively adsorb gas molecules. When the molecular sieve is saturated with adsorption, it is released by heating to restore its adsorption capacity.

Recommended products