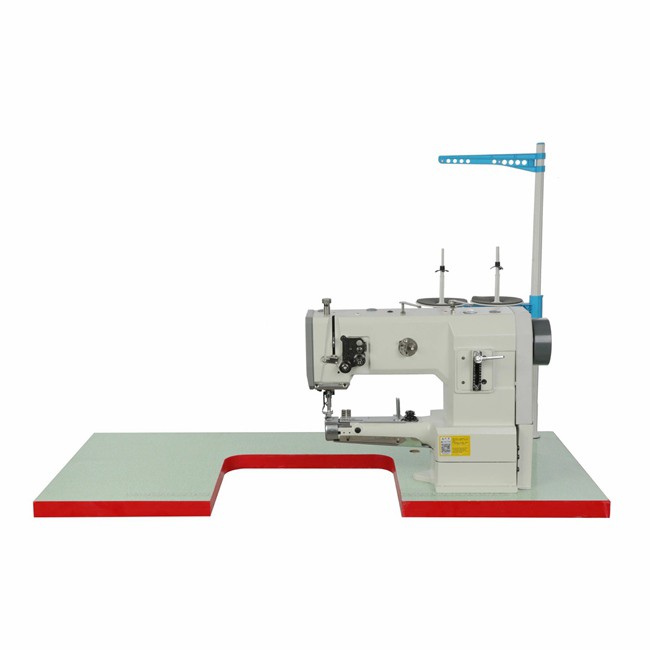

Factory Supplier Direct Drive Computerized Lockstitch Industrial Sewing Machine

Product description

Computer controlled sewing machines perform well in terms of automation, precision, multifunctionality, ease of operation, low noise and vibration, and cleanliness and environmental protection. It is one of the essential high-precision equipment in modern sewing industry, widely used and favored by various industries. With the continuous advancement of technology and changes in market demand, the performance and functionality of computerized sewing machines will continue to improve and perfect.

In addition to basic functions such as flat sewing, edge locking, and patching, computer sewing machines can also set specific sewing parameters according to user needs, and even customize sewing programs to sew different patterns and styles. This programmability makes computer sewing machines have great potential in the field of personalized customization. Computer sewing machines focus on optimizing low noise and low vibration in the design and manufacturing process, making the machine run more smoothly and quietly, providing a better working environment for operators.

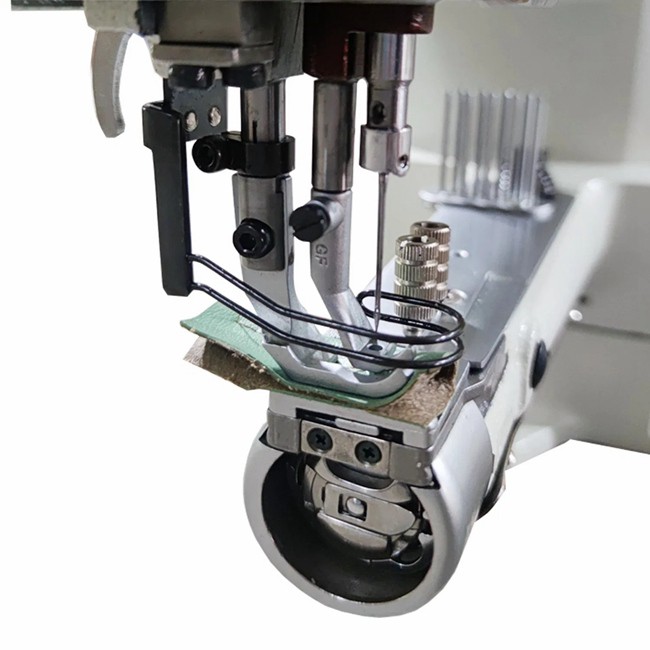

Computer controlled sewing machine, also known as computerized sewing machine, is an important achievement of modern sewing technology. Computerized sewing machine adopts computer precision control, which can achieve high-precision sewing operations, uniform and beautiful sewing lines, and excellent sewing effects. This is particularly important for industries that require high-quality sewing products. The computer sewing machine can automatically complete the set sewing work, including automatic edge sewing, automatic adjustment of thickness and seam tension, automatic speed change, automatic torque change, automatic thread cutting, automatic needle patching, etc. These functions greatly reduce the labor intensity of operators and improve production efficiency.

In today's industrialization, industrial sewing machines have become an indispensable production tool in the textile and garment industry. They not only improve production efficiency and reduce production costs, but also promote the diversification and personalized development of product design. By flexibly configuring different types of sewing machines, enterprises can easily respond to various complex production demands and market changes, and maintain a competitive advantage.

On the vast stage of the textile and garment industry, industrial sewing machines, as the core production equipment, continue to drive the progress and development of the industry with their efficient, precise, and diversified sewing capabilities. Flat sewing machine is the most common type of industrial sewing machine used for sewing straight and simple curves, widely used in clothing, luggage, footwear and other fields.

Recommended products