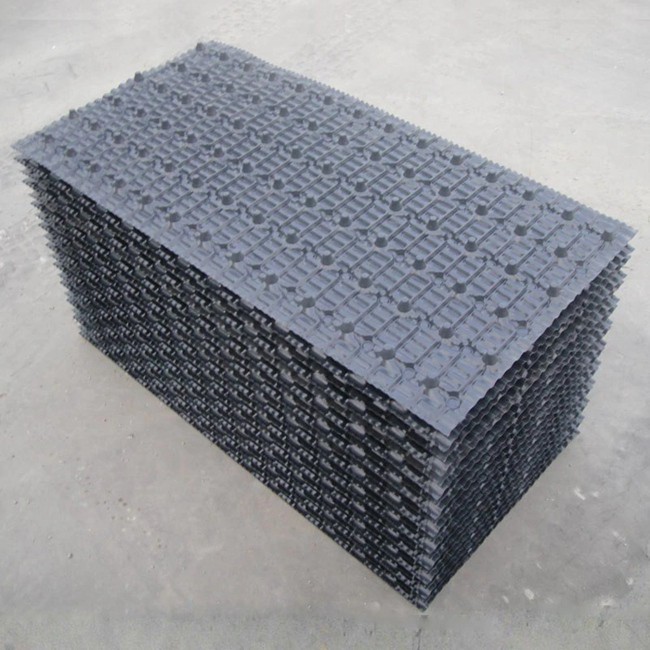

High Quality New Material Cooling Tower Infill PVC Filler

Product description

PVC cooling tower packing has been widely used and recognized in the field of cooling towers due to its excellent corrosion resistance, high temperature resistance, good breathability and ventilation performance, convenient installation and maintenance, relatively low cost, diverse structural types, and environmental friendliness. With the continuous development and progress of industrial technology, PVC fillers will continue to play an important role in the future, providing efficient and reliable solutions for the heat dissipation needs of various industries.

PVC material has a relatively small impact on the environment during production and use, which meets the requirements of modern industry for sustainable development. In addition, PVC fillers do not release toxic substances at high temperatures, which is beneficial for people's lives and health. And compared to some high-performance filler materials such as FRP (glass fiber reinforced plastic), the cost of PVC filler is relatively low. This makes PVC fillers an ideal choice in economically demanding situations. Its high cost-effectiveness can meet general heat dissipation needs while also controlling costs.

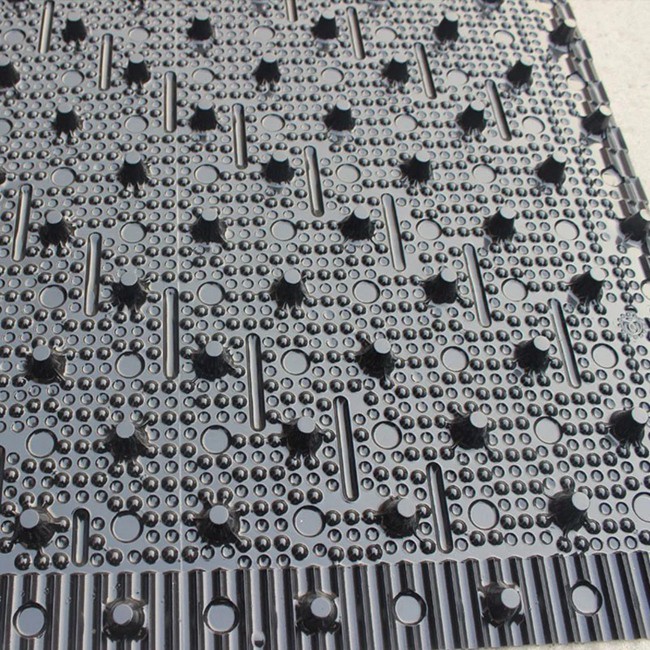

The corrugated or hexagonal structure design of PVC filler significantly increases the permeability and ventilation area of the filler bed. This design allows air to pass through the packing layer more smoothly and come into full contact with hot water, thereby improving heat exchange efficiency and enhancing cooling effect. PVC filler is lightweight and easy to process, so it can save a lot of manpower and time costs during installation. At the same time, its surface is smooth and not prone to scaling, which also reduces the difficulty of cleaning and maintenance. These characteristics make the application of PVC fillers in cooling towers more convenient and economical.

PVC fillers have been widely recognized and applied in multiple fields due to their excellent performance, wide range of applications, and low cost. In the future, with the continuous advancement of technology and the expansion of the market, PVC fillers will continue to play an important role and contribute more to the development of various industries.

PVC fillers are known for their excellent chemical inertness, corrosion resistance, and wear resistance. It can maintain stable performance in various harsh environments and withstand long-term corrosion from chemical substances and impact from high-temperature fluids. In addition, PVC fillers also have excellent breathability and ventilation performance, thanks to their corrugated or hexagonal structure, which can significantly increase the breathable area of the filler bed and improve the efficiency of heat and mass exchange.

Recommended products