Best Price Durable Ultra Fine Stainless Steel Metal Woven Wire Mesh Filter Screen

Product description

In order to maintain the good performance and prolong the service life of stainless steel screen mesh, you need to regularly use water or mild detergent to clean the surface of the screen mesh to remove the attached dirt and impurities. For residues that are difficult to clean, a soft bristle brush or high-pressure water gun can be used. Regularly check the wear and tear of the screen mesh and whether the mesh holes are clogged. If any serious wear and tear or clogged mesh holes are found, the screen should be replaced or cleaned in time.

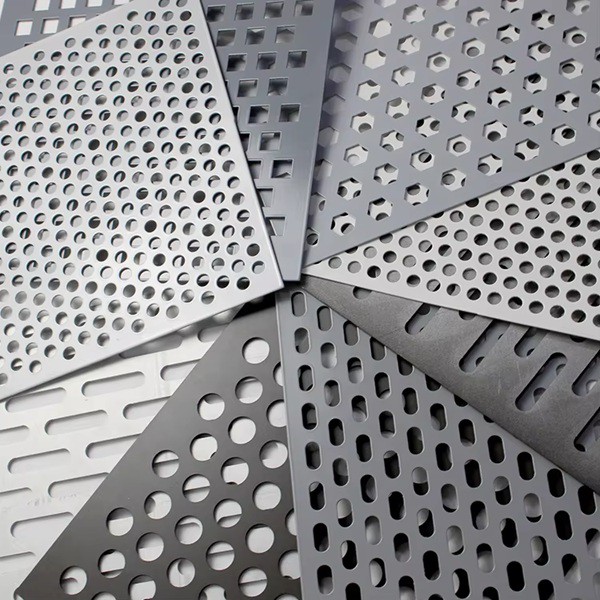

Ultra-fine sieve mesh can effectively separate out the fine particles in the material to ensure the purity and uniformity of the product. High temperature resistance, acid and alkali resistance: many ultra-fine screens are made of stainless steel, which has excellent high temperature resistance, acid and alkali resistance, and can operate stably in harsh working environments. High-quality stainless steel wires are woven into the screen mesh, which has good abrasion resistance and prolongs the service life. According to the customer's demand, we can customize the screen mesh with different sizes, hole types and precision to meet the diversified production needs.

Ultrafine screen mesh is usually made of stainless steel wire or galvanized wire as raw material, woven by precision machinery. Its structure is compact, smooth and flat surface, beautiful and generous. Common screen materials include low carbon steel wire, stainless steel wire, etc. Stainless steel screen is widely used in many industries due to its excellent corrosion resistance and high temperature resistance.

Ultrafine screen mesh has a wide range of applications, covering almost all industries that require fine screening. In the production process of Chinese medicine powder and other pharmaceutical products, ultra-fine sieve mesh is used for sieving and grading of powdered raw materials to ensure the quality and purity of drugs. In the process of food additives, flour and other food raw materials, ultrafine sieve mesh is used to sieve flour, remove impurities, improve the taste and quality of food. In the screening and filtration of chemical raw materials, ultra-fine sieve mesh can separate the fine particles in the material to ensure the purity and uniformity of the product. In the field of waste water treatment, air purification and other environmental protection, ultra-fine sieve mesh is used to filter out the tiny suspended particles and particulate matter, purify water and air.

Due to the tiny aperture of the screen, it is easy to be clogged, so it needs to be cleaned regularly to ensure its screening efficiency. When cleaning, it can be soaked in hot soapy water or detergent foam water, then gently brushed with a brush, and finally rinsed with flowing water. For residues that are difficult to clean, toothpicks, needles and other fine tools can be used to clean. In order to extend the service life of ultrafine screen, you also need to pay attention to the following points: avoid prolonged exposure to high temperatures, humid environments; avoid direct contact with sharp objects in order to prevent scratches; regularly check the wear and tear of the screen and replace damaged parts in a timely manner.

Recommended products