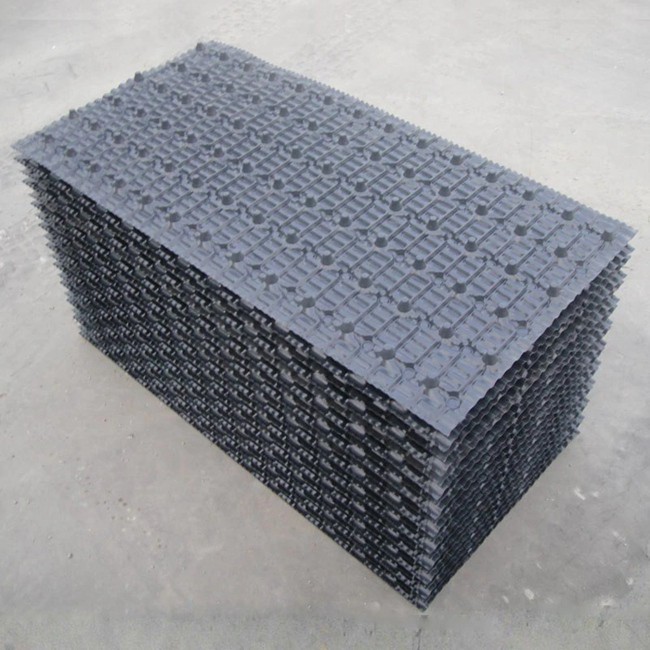

High Quality Flow PVC Film Fill Marley Hanging Type Cooling Tower Filler

Product description

PVC material has good chemical stability and can resist the erosion of various chemicals. During the operation of cooling towers, it is often necessary to handle various chemicals and high-temperature fluids, so the corrosion resistance and high-temperature resistance of the packing are crucial. PVC filler can operate stably for a long time in such an environment, ensuring the performance and lifespan of the cooling tower.

With the continuous progress of science and technology and the continuous development of industrial technology, the application scope of PVC fillers will continue to expand. In the future, PVC fillers are expected to leverage their unique advantages in more fields, providing efficient and reliable solutions for the heat dissipation, filtration, and purification needs of various industries. Meanwhile, with the increasing awareness of environmental protection and the deepening of sustainable development concepts, the environmental friendliness of PVC fillers will also become one of the important directions for their future development.

In the fields of environmental protection and water treatment, PVC fillers are widely used in various equipment, such as cooling towers, bioreactors, etc. Its main function is to increase the solubility of oxidizing gases in water, improve the biological quality of water, and help remove harmful substances such as organic compounds, ammonia nitrogen, hydrogen sulfide, etc. from water through its huge surface area. These characteristics of PVC fillers make it an indispensable and important material in the water treatment industry.

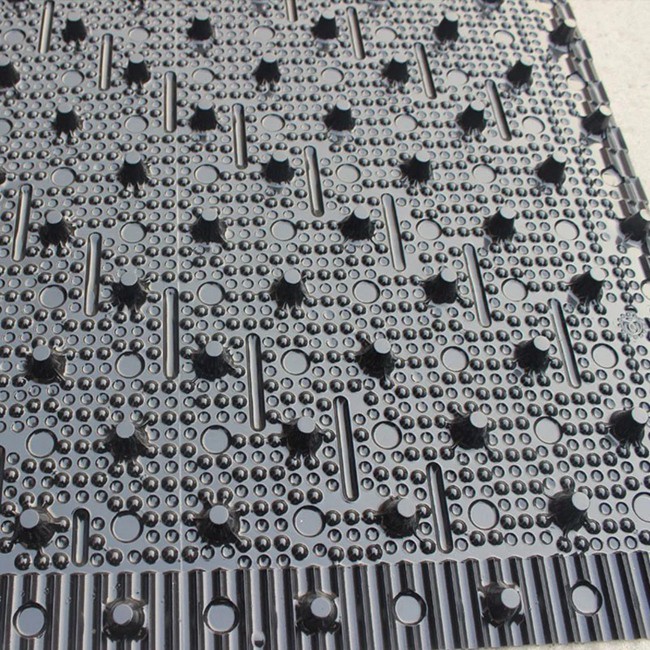

PVC fillers are known for their excellent chemical inertness, corrosion resistance, and wear resistance. It can maintain stable performance in various harsh environments and withstand long-term corrosion from chemical substances and impact from high-temperature fluids. In addition, PVC fillers also have excellent breathability and ventilation performance, thanks to their corrugated or hexagonal structure, which can significantly increase the breathable area of the filler bed and improve the efficiency of heat and mass exchange.

PVC (polyvinyl chloride) filler, as a widely used plastic filler, has demonstrated its unique advantages in various fields such as chemical engineering, environmental protection, water treatment, and air treatment. Another major advantage of PVC filler is its light weight, ease of processing and installation. This not only reduces installation costs, but also facilitates subsequent maintenance and cleaning work. At the same time, the surface of PVC filler is smooth and not easy to scale, which helps to maintain the cleanliness and efficient operation of equipment.

Recommended products