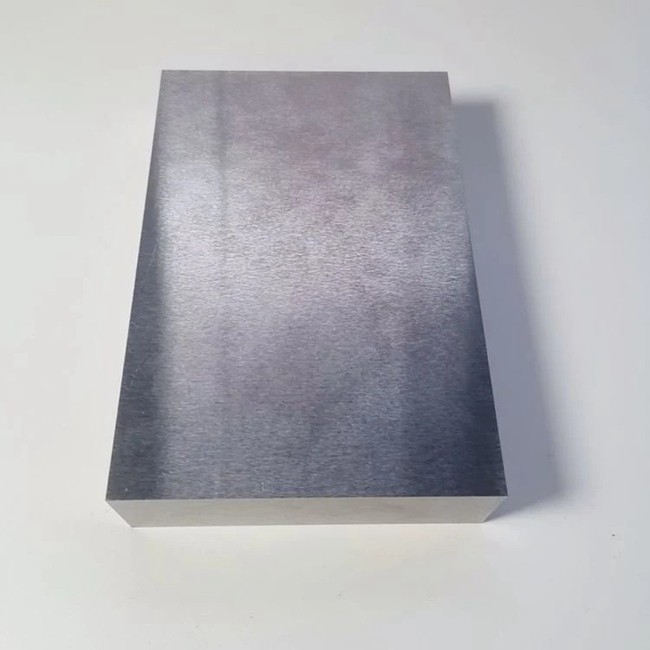

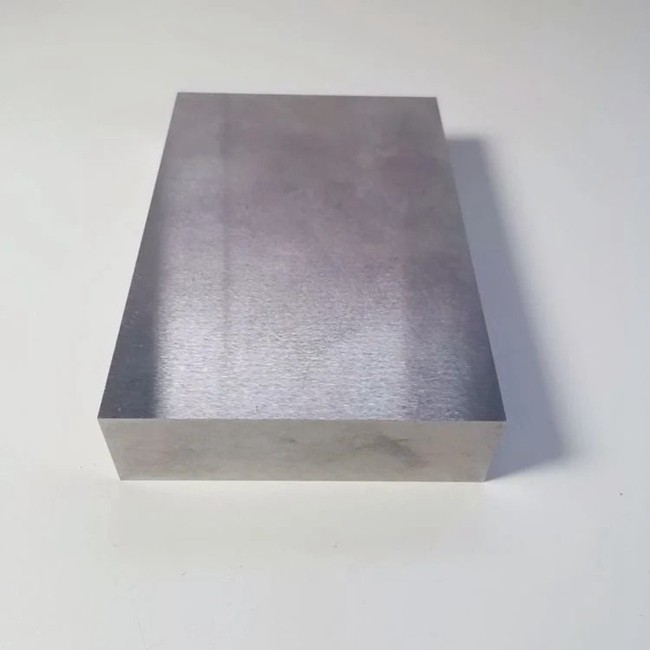

Professional Wear Block Cemented Tungsten Carbide with High Hardness Grade

Product description

As a metal carbide with excellent performance, tungsten carbide plays an important role in several industrial fields. It is not only a hard and sharp edge for cutting tools and molds, but also a powerful assistant in mining, drilling, wear-resistant parts and aerospace. With the continuous progress of technology and the expansion of application areas, the future of tungsten carbide will be brighter.

Tungsten carbide has a wide range of applications in many occasions due to its excellent properties such as high hardness, high wear resistance and high corrosion resistance. Tungsten carbide is the main raw material for manufacturing tungsten carbide tools (such as drills, milling cutters, turning tools, etc.). These tools play a key role in metal processing, wood processing, stone processing and other industries, and are able to cut a variety of materials efficiently and accurately. In mold manufacturing, tungsten carbide is also often used to make mold cores, punches, mold inserts, etc. to improve the wear resistance and service life of molds.

Tungsten carbide is used in the manufacture of a variety of wear-resistant parts and components such as bearings, sealing rings, and nozzles. These parts maintain long service life and stable performance when operating at high speeds, high temperatures, high pressures or in corrosive environments. Tungsten carbide coatings and films are widely used in mechanical parts, electronic components, medical devices and other fields due to their excellent wear resistance, corrosion resistance and high temperature stability. These coatings and films can be prepared by chemical vapor deposition, physical vapor deposition and other methods to improve the surface properties of the base material.

In the aerospace field, tungsten carbide is used to manufacture high-temperature components such as nozzles for jet engines and blades for gas turbines. These components are required to operate at high temperatures, high speeds and in harsh environments, and tungsten carbide's high melting point and excellent thermal stability make it an ideal choice. Tungsten carbide is also used in the manufacture of ceramic cutting tools, abrasives and grinding tools. In ceramic processing, glass processing, stone processing and other industries, tungsten carbide tools are favored for their high hardness and wear resistance.

Tungsten carbide, a black hexagonal crystal synthesized from the elements tungsten and carbon through a specific process at high temperature, has a metallic luster. Its extreme hardness, second only to diamond in nature, makes it one of the hardest known metal carbides. This extraordinarily high hardness gives tungsten carbide excellent wear and corrosion resistance, making it an ideal material for many industrial applications.

Recommended products