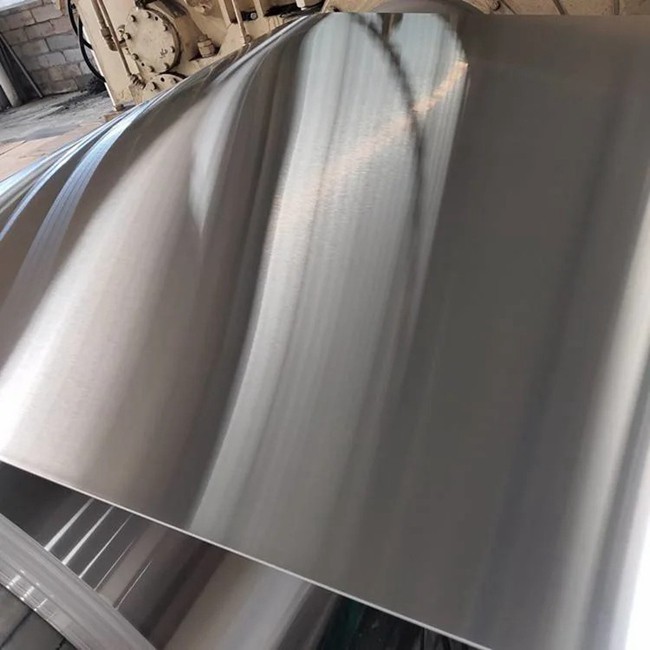

High Quality Building Material Roofing Sheets Steel-Products Carbon Steel Coil

Product description

Hot dip galvanized steel coils are commonly used in fields that require high corrosion resistance and strength, such as marine engineering, chemical engineering, shipbuilding, aerospace, etc., due to their excellent anti-corrosion performance and strength. In these fields, hot-dip galvanized steel coils can effectively resist the erosion of materials by harsh environments. Cold dip galvanized steel coils are commonly used in fields such as construction, home appliances, automobiles, and light industry. Although its anti-corrosion performance is not as good as hot-dip galvanized steel coils, its cost is relatively low and it can meet the anti-corrosion requirements in general environments.

Galvanized steel coil refers to a layer of zinc metal coated on a steel plate to achieve anti-corrosion and aesthetic effects. This category usually includes hot-dip galvanized steel coils and cold-dip galvanized steel coils, but when referring to galvanized steel coils, it mostly refers to cold-dip galvanized steel coils. Hot dip galvanized steel coil is a special type of galvanized steel coil, whose galvanizing process involves heating the original steel plate to a certain temperature and immersing it in molten zinc solution for galvanizing treatment. This method forms a thick layer of zinc alloy on the surface of the steel plate.

Galvanized steel coils are commonly used for components in building structures, such as beams, columns, purlins, as well as for building roofs, walls, and other areas. Its excellent anti-corrosion performance can protect building materials from corrosion by the atmosphere and water. Galvanized steel coils are also widely used in automobile manufacturing, such as manufacturing car bodies, doors, engine covers, and other components. Its corrosion resistance helps to extend the service life of automotive components.

Galvanized steel coil is a steel plate material formed by galvanizing hot-rolled or cold-rolled steel strip as the substrate. Galvanized steel coils are coated with a layer of zinc on the surface of the steel to enhance its corrosion resistance, wear resistance, aesthetics, and processing performance. This layer of zinc not only effectively prevents the oxidation of steel, but also forms a protective film on the surface of the steel, thereby extending its service life.

Recommended products