Professional stainless steel hot rolled strip supplier

Product description

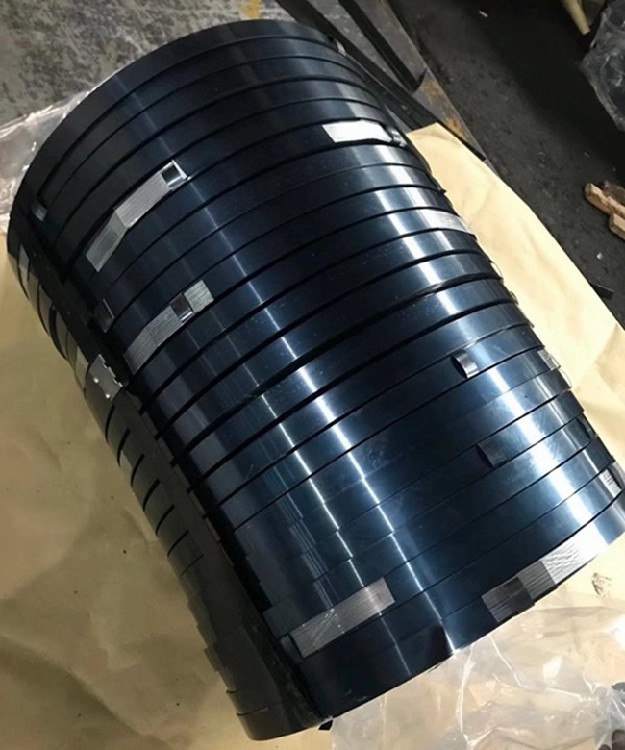

(stainless steel hot rolled strip)

Hot-rolled stainless steel strip is made from hot-rolled stainless steel strip as blank and further hot-rolled. Compared with cold-rolled strip, it has higher dimensional accuracy, low surface roughness, good surface quality, smoothness, and higher strength. Therefore, thinner hot-rolled strip can replace thicker cold-rolled strip for the same purpose to save steel, which is of great economic significance. Hot-rolled stainless steel strip is divided into five types according to its organizational characteristics: austenite, austenite-ferrite, ferrite, martensite and precipitation hardening, which can be selected when used. (1) Main characteristics and uses (2) Material grade and chemical composition (3) Mechanical properties (4) Strip steel specifications 0.70, 0.80, 0.90, 1.00, 1.20, 1.50, 2.00, 2.50, 3.00, 4.00 mm.

Testing standards

1. American ASTM standards

ASTM A240 and ASTM A480 are standards related to hot-rolled stainless steel plates and strips in the American ASTM international standards. Among them, ASTM A240 specifies the classification, code, specification, appearance quality, chemical composition, mechanical properties, test methods, marking, packaging, quality certification and other requirements for hot-rolled steel plates and strips of ferritic stainless steel, austenitic stainless steel and duplex stainless steel. ASTM A480 specifies the standard specifications of general stainless steel plates and strips and thick steel plates.

2. European standards

There are several standards related to hot-rolled stainless steel plates and strips in European standards, mainly including EN10088-2, EN10028-7 and EN10151. EN10088-2 specifies the standard specifications of hot-rolled stainless steel plates and strips for general stainless steel, EN10028-7 specifies the standard specifications of stainless steel high-temperature pressure vessel plates, and EN10151 specifies the standard specifications of stainless steel spring plates and strips and spring steel wires.

3. Chinese Standard

Standard "Hot-rolled Stainless Steel Plates and Strips" (GB/T 14976)

This standard specifies the classification, code, specification, appearance quality, inspection method, test method, marking, packaging, storage and transportation, and quality certification requirements of hot-rolled stainless steel plates and strips.

Application scope of standards

Different standards have different applicability and application scope for different hot-rolled stainless steel products. For example, GB/T 14976 is applicable to hot-rolled steel plates and strips of ferritic stainless steel and chromium-nickel stainless steel, while YB/T 4207 is applicable to the manufacture of cold-rolled stainless steel sheets and strips. Therefore, in actual production and use, the appropriate standard should be selected according to the different characteristics of the product.

Process flow

Raw material preparation: Select suitable stainless steel raw materials, usually stainless steel billets or cut plates. According to product requirements, the raw materials are cut, trimmed, polished and other processes.

Heating treatment: The raw materials are placed in a heating furnace for heating treatment to improve their plasticity and machinability. The heating temperature is generally above 1000℃, and the specific temperature depends on the composition of the stainless steel and product requirements.

Hot rolling: The heated raw materials are sent to the rolling mill for hot rolling. Hot rolling generally uses a continuous rolling mill, and through multiple passes of rolling, the raw materials are gradually rolled into the required thickness and shape. During the rolling process, the stainless steel billet is extruded and deformed by multiple rollers, and is controlled by cooling and water spraying to adjust the temperature and shape.

Cooling and subsequent treatment: The stainless steel products after hot rolling are cooled, generally using gas cooling or water cooling. After cooling, subsequent processing such as straightening, trimming, and grinding can be carried out to finally obtain stainless steel products that meet the requirements.

The stainless steel hot rolling process transforms the stainless steel billet into the required product shape and size through heating, rolling and subsequent processing. The steel plates or strips produced by this process have the characteristics of uniform thickness, smooth surface and excellent mechanical properties, and are widely used in industries such as petroleum, chemical, construction, and food.

Precautions

1. When checking the operation of the equipment, the operator on the platform must be notified and the whereabouts must be explained to ensure safe operation.

2. When handling waste products, there must be a dedicated person on site to command and monitor to ensure safe operation.

3. When entering the coiler for operation, all the upper tension rollers of the coiler must be dropped, the valve closed, the upper guide roller table raised, the forming roller switched to the maximum limit, and the safety pin inserted to ensure safe operation.

Hydraulic system maintenance: When the hydraulic system is repaired, the pump must be stopped and the pressure must be relieved. Hot work must go through the hot work approval procedures and implement corresponding fire prevention measures.

4. During the leveling and splitting process, pay attention to the position to prevent the coil tail from bouncing off and injuring people. Before starting the loading step beam, it must be confirmed that the overhead crane clamp has left the steel coil to avoid burns.

Recommended products