High Quality Electric Domestic Maize Grinding Wheat Bran Feed Crusher

Product description

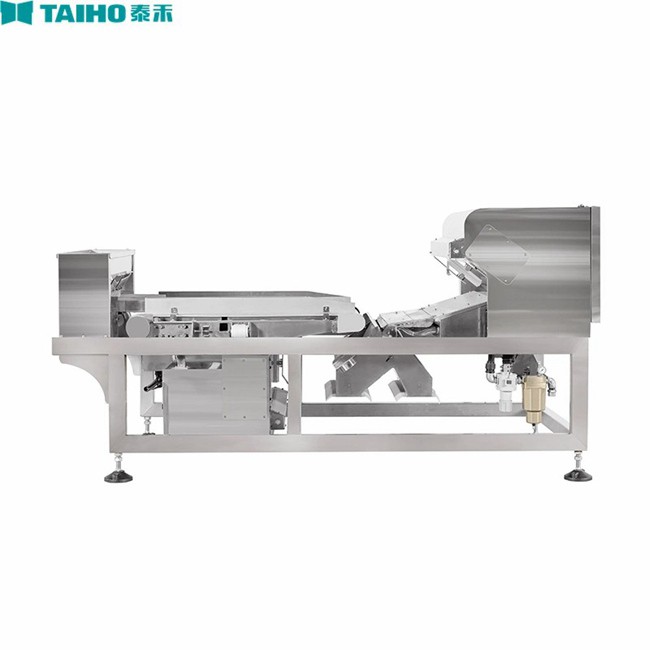

Corn milling machine is mainly based on the principle of mechanical pulverization, cutting, grinding and crushing corn particles through high-speed rotating blades or hammer blades, and ultimately converting them into fine powder or granules. Its construction usually includes feeding device, crushing chamber, screen, motor and transmission system and other parts. When working, the motor drives the spindle to rotate, driving the blade or hammer blade to rotate rapidly, and the corn particles are subjected to strong impact and shear in the crushing chamber, so as to realize the purpose of crushing.

In the development process of modern agriculture, mechanization and automation have become an important driving force to improve production efficiency and guarantee food security. Among them, corn milling machine as an important member of agricultural processing equipment, with its high efficiency and convenient features, plays an irreplaceable role in the deep processing of corn and other crops. In this paper, we will discuss in depth the principle, application, advantages and future development trend of corn milling machine.

The price of corn milling machine varies according to brand, model, function and other factors. Generally speaking, the price of household small corn mill is more friendly and suitable for family use; while commercial large corn mill is more expensive, but more powerful and suitable for large-scale production. In the market, users can choose the right product according to their needs and budget.

When using a corn milling machine, you need to pay attention to the following points:

Before use, make sure the power is off and operate it correctly according to the instructions. When using, pay attention to personal safety and avoid direct contact with rotating parts.

The crushed material must be dry, and should not be processed wet and greasy materials. At the same time, the crushed drugs do not exceed half of the capacity of the crushing tank.

After long-term use, carbon brushes and blades such as serious wear and tear, need to be replaced in a timely manner. In addition, you also need to frequently check whether the screws of the blade are tight, to ensure the normal operation of the machine.

Recommended products