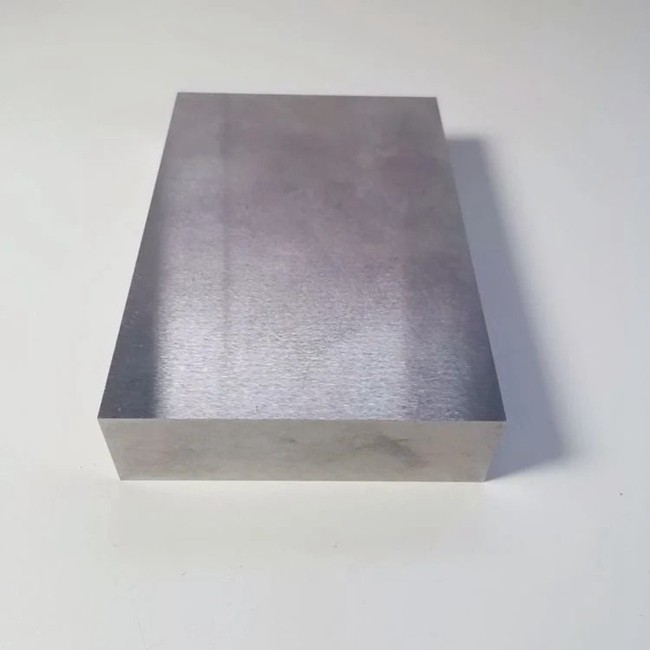

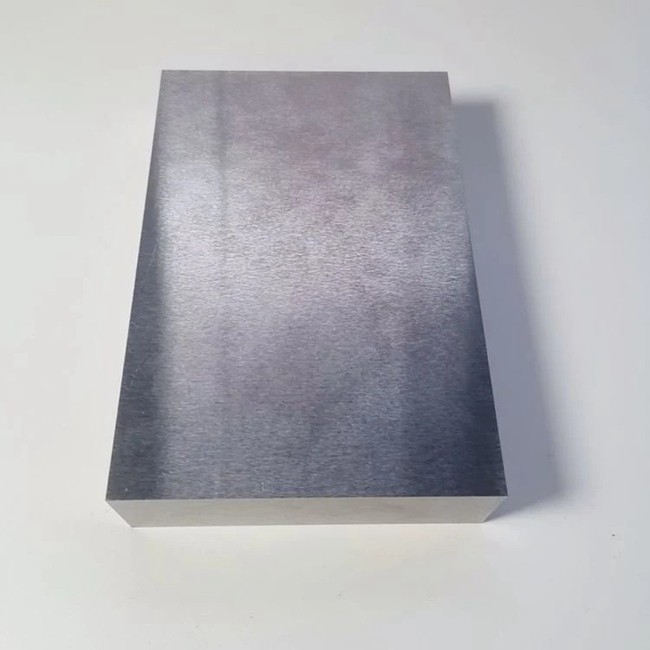

Professional Carbide Square Bar Tungsten Carbide Tool Parts

Product description

Tungsten carbide also plays an important role in mining and drilling. Drill bits in oil and gas drilling often contain tungsten carbide to cope with hard rocks and formations. The high hardness and abrasion resistance of tungsten carbide allows the drill bit to penetrate formations more quickly, increasing drilling efficiency. Meanwhile, in mining operations, tungsten carbide is also used to manufacture wear-resistant parts such as crusher hammer heads and grinding media to cope with harsh working conditions.

Tungsten carbide is chemically stable, insoluble in strong acids such as water, hydrochloric acid and sulfuric acid, but readily soluble in a mixture of nitric acid-hydrofluoric acid. Pure tungsten carbide is fragile, but its brittleness can be reduced by doping a small amount of titanium, cobalt and other metals.

Due to its excellent properties such as high hardness, high wear resistance and high corrosion resistance, tungsten carbide is the main raw material for the production of cemented carbide, which is widely used in cutting tools, molds, wear-resistant parts and other fields. Tungsten carbide coating has excellent wear resistance, impact resistance and corrosion resistance, and is used for surface treatment of bearings, valves, pumps and other parts.

In mining operations, tungsten carbide is also used in the manufacture of crusher hammer heads, grinding media, etc. to cope with harsh working conditions. Due to its high hardness and wear resistance, tungsten carbide has a wide range of applications in mining and drilling. For example, drill bits in oil and gas drilling often contain tungsten carbide to improve their ability to penetrate rocks and strata. Tungsten carbide plays an important role in cutting tools and dies, mining and drilling, wear-resistant parts and components, coatings and films, aerospace, and other industrial applications.

Recommended products