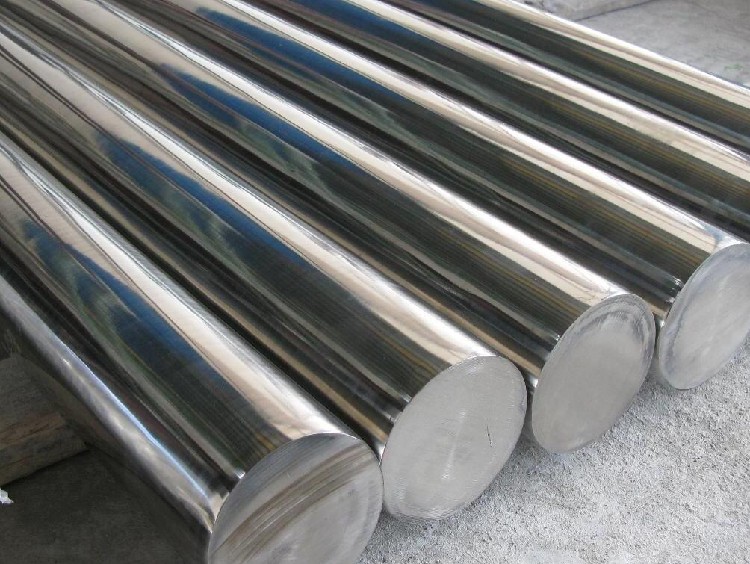

304 vs 301 stainless steel

Product description

301 stainless steel strip is a metastable austenitic stainless steel that has a complete austenitic structure under full solid solution conditions. Among stainless steels, 301 is the steel type that is most easily strengthened by cold deformation. Through cold deformation processing, the strength and hardness of the steel can be improved, and sufficient plasticity and toughness can be retained. In addition, this steel has good rust resistance under atmospheric conditions. However, it has poor corrosion resistance in reducing media and poor corrosion resistance in acid, alkali, salt and other chemical media, so it is not recommended for use in harsh corrosive environments.

Advantages and Disadvantages

The advantages of 301 stainless steel include high strength, good ductility, easy cold deformation strengthening, and good rust resistance under atmospheric conditions. Through cold deformation processing, the strength and hardness of 301 stainless steel can be significantly improved while retaining sufficient plasticity and toughness. In addition, it is prone to work hardening when impacted by external forces, and can absorb more impact energy, providing more reliable safety protection for equipment and personnel. The density of 301 stainless steel is 7.93 g·cm^-3, tensile strength ≥520 conditional yield strength ≥205 , elongation ≥40%. These mechanical properties make it desirable to withstand higher loads while Excellent in applications that reduce equipment weight.

However, the disadvantages of 301 stainless steel include poor corrosion resistance in reducing media and poor corrosion resistance in chemical media such as acids, alkalis, and salts. Therefore, it is not recommended for use in harsh corrosive environments. Since 301 stainless steel contains less Cr and Ni elements, the tensile strength and hardness increase during cold working, but it is non-magnetic, but may show magnetism after cold working. These characteristics limit its application in specific environments.

Stainless steel price

Stainless steel seamless pipe, on September 2, the price of stainless steel seamless pipe was mainly stable. In terms of price, the mainstream transaction price of 304Ф108*4 is around 16700-17700 yuan/ton; the mainstream transaction price of 316LФ108*4 is around 26700-31400 yuan/ton. The prices of related varieties have not fluctuated significantly, and they are still selling at a stable price. Demand has emerged periodically, and it has entered the peak sales season. The quotations of pipe factories have increased, and low prices have increased. Small profits and quick turnover have become the main strategies.

Differences between 304 and 301 stainless steel

304 and 301 stainless steel are two common austenitic stainless steels, and the main differences between them are chemical composition, mechanical properties, and corrosion resistance.

Chemical composition differences:

The nickel (Ni) content in 304 stainless steel is usually between 8%-10%, while the nickel content of 301 stainless steel is lower, about 6%-8%. The chromium (Cr) content in 304 stainless steel is between 18%-20%, while the chromium content of 301 stainless steel is slightly lower, about 16%-18%.

301 stainless steel contains a higher carbon (C) content, usually between 0.15%-0.20%, while 304 stainless steel has a lower carbon content of about 0.08%. The difference in carbon content leads to differences in mechanical properties and work hardening ability between the two.

Mechanical property differences:

Due to the higher carbon content of 301 stainless steel, it is easy to produce a work hardening effect during cold working, thereby obtaining higher strength. This makes 301 stainless steel perform well in applications that require a certain strength.

304 stainless steel has better plasticity and toughness due to its high nickel content. It is not easy to break at room temperature and is more suitable for structural parts that bear impact loads.

Corrosion resistance difference:

The corrosion resistance of 304 stainless steel is better than that of 301 stainless steel. This is mainly because the nickel content in 304 stainless steel is high, and nickel can effectively improve the corrosion resistance of the material. In oxidizing environments, such as nitric acid and sulfuric acid, the corrosion resistance of 304 stainless steel is particularly outstanding.

301 stainless steel performs well in some reducing environments, but its corrosion resistance in oxidizing environments is relatively poor, especially when the carbon content is high, it may form pitting or intergranular corrosion under the action of corrosive media.

Application field difference:

Due to the good corrosion resistance and forming performance of 304 stainless steel, it is widely used in the food industry, chemical industry, architectural decoration, medical equipment and other fields.

Due to its high strength and work hardening ability, 301 stainless steel is often used to manufacture products that require high mechanical strength, such as springs, fasteners, and automotive accessories.

Recommended products