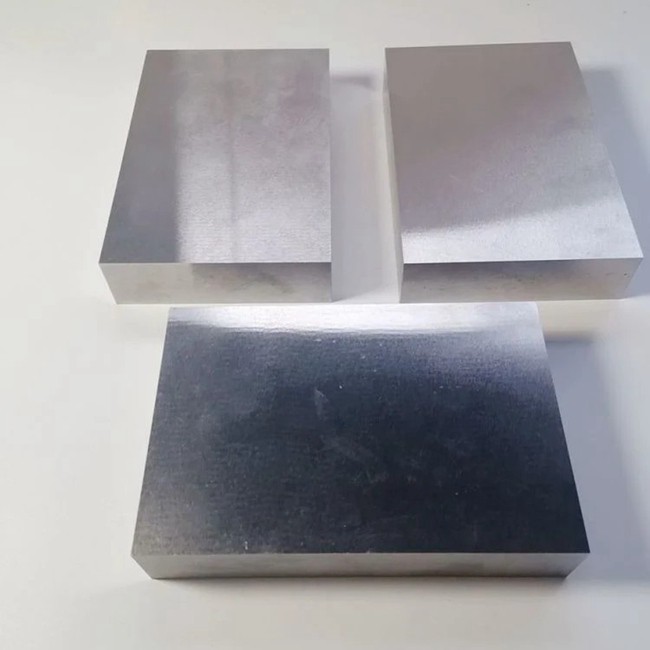

Factory Made Carbide Sheet Tungsten Steel Plate for Mold Making

Product description

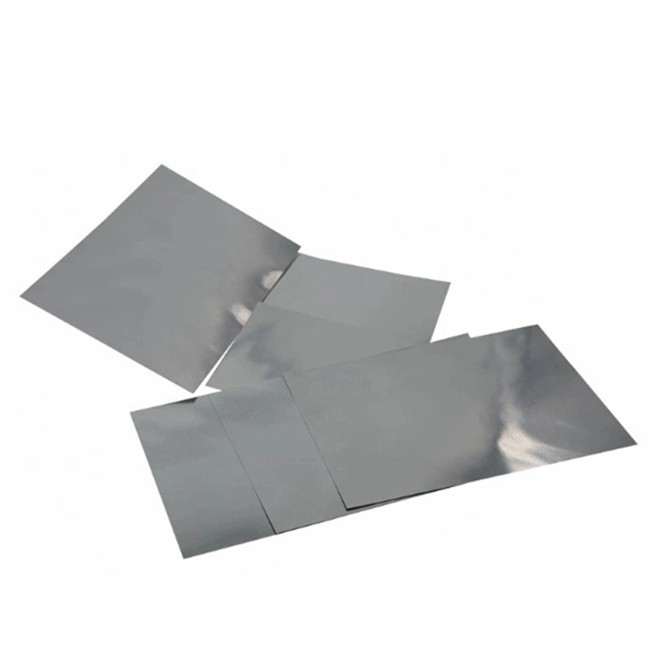

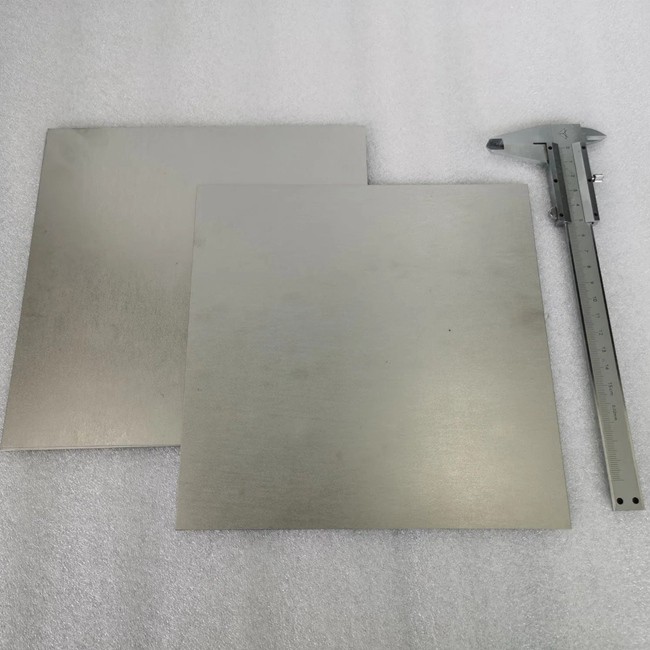

Tungsten alloy plates also have good mechanical properties, including high strength, high hardness and good wear resistance. These properties make tungsten alloy plates widely used in machining, mold making and other fields, and can withstand high loads and high abrasion working environments. Tungsten alloy plates also have excellent thermal stability and corrosion resistance. The high melting point of tungsten allows the alloy plate to maintain good performance in high temperature environments, while its resistance to a wide range of chemicals allows it to work in harsh chemical environments, such as applications in chemical equipment and nuclear energy facilities.

Tungsten alloy plate is a kind of composite plate synthesized from tungsten and other metals (e.g. nickel, iron, copper, etc.) through a special process. With its unique physical and chemical properties, this alloy has shown great application value in many fields. Tungsten alloy plates are known for their extremely high density, which gives them excellent weight-carrying capacity and compression resistance. This high density property makes tungsten alloy sheet perform well in applications that require high weight or high density materials, such as armor-piercing bullets in the military and counterweights for sports equipment.

In the field of nuclear energy, tungsten alloy plate is especially widely used. It can be used as a structural material for nuclear reactors, such as the core and reactor vessel lining; at the same time, its high density and high absorption properties make it a radiation shielding material for nuclear energy facilities, which is used to reduce the impact of radiation on the interior of the facility and the surrounding environment. In addition, tungsten alloy sheet is also used to manufacture components such as cladding and absorber rods for nuclear fuel elements to ensure the safe operation of nuclear reactors.

Tungsten alloy plate is a dense, radiation-absorbing material that can effectively resist and absorb the effects of high-energy radiation from X-rays, γ-rays and neutron radiation. This characteristic makes it widely used in the nuclear industry, medical equipment and aerospace and aviation, etc., for the manufacture of radiation protection and ray diagnostic equipment.

Due to its high density and high strength characteristics, tungsten alloy plate is widely used in the manufacture of a variety of defense and military equipment, such as heavily armored kinetic energy armor-piercing bullets, bullets, rifles, missiles and bombs. At the same time, tungsten alloy plate is also used in the manufacture of some special-purpose counterweights, such as yacht counterweights and airplane ballasts.

The density of tungsten alloy plate is extremely high, generally between 16.5~19.0g/cm³, which is equivalent to more than twice the density of steel. This characteristic gives it excellent tensile strength and compression resistance. The tensile strength of W-Ni-Fe high-density alloy in sintered state can be up to 800~1000MPa, and the strength can be further increased to 1300~1500MPa after heat treatment and deformation processing.

Recommended products