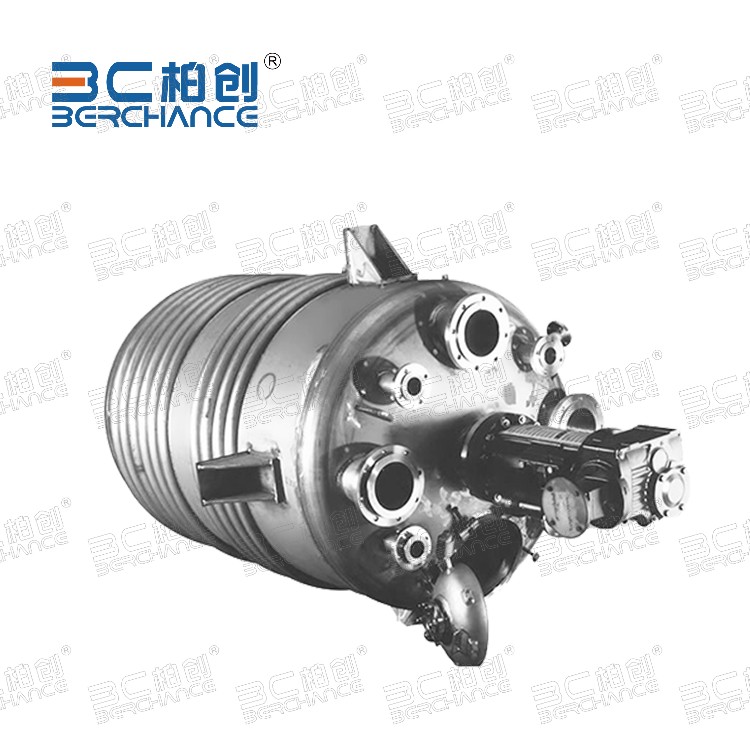

China Factory 304 316/Titanium/PTFE/PE/Glass/Enamel Double Jacket Heating Chemical Mixing Reaction Kettle

Product description

Distillation vessels are widely used in various industries such as pharmaceuticals, chemicals, food, and light industry. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs, such as extracting essential oils from plants or separating target products from fermentation broth. In the chemical industry, distillation kettles are used for the purification and separation of various chemicals, such as fraction cutting in petroleum processing and product purification in organic synthesis. In addition, in the food industry, distillation kettles are also used in the production process of extracting substances such as spices and alcohol.

Reaction vessels are widely used in industries such as petroleum, chemical, rubber, pesticides, dyes, pharmaceuticals, and food. In these industries, reaction vessels are used to complete processes such as sulfurization, nitration, hydrogenation, alkylation, polymerization, and condensation. For example, in the pharmaceutical industry, reaction vessels are used as critical steps in drug synthesis processes; In the chemical industry, it is used for the synthesis and purification of various chemicals.

A reaction kettle is a comprehensive reaction vessel widely used in industries such as chemistry, medicine, and food. It achieves the required heating, evaporation, cooling, and material mixing functions through specific design structures and parameter configurations. A reactor is a container that undergoes physical or chemical reactions. The structure and parameter configuration of the container are designed according to different process conditions to achieve specific reaction processes.

Distillation kettle is one of the indispensable and important equipment in chemical production, with a compact structure, easy operation, good separation effect, and a wide range of applications. With the continuous advancement of technology and the expansion of application fields, the performance and functionality of distillation kettles will also be further improved and perfected. The distillation kettle converts electrical energy into thermal energy to heat materials, which has the advantages of easy cleaning, high efficiency (with an electrical energy utilization rate of over 95%), heating temperature of over 3000 ℃, and easy adjustment.

In the vast field of chemical industry, distillation kettle plays an indispensable role as a key separation equipment. It utilizes the difference in boiling points of each component in the mixture to achieve effective separation of components through processes such as heating, vaporization, and condensation, providing important technical support for chemical production. The main function of a distillation kettle is to vaporize the distilled liquid and provide the necessary amount of rising steam in the tower to achieve effective separation of components. Widely used in pharmaceutical, chemical, food, light industry and other fields. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs; In the chemical industry, it is used for the purification and separation of various chemicals.

Recommended products