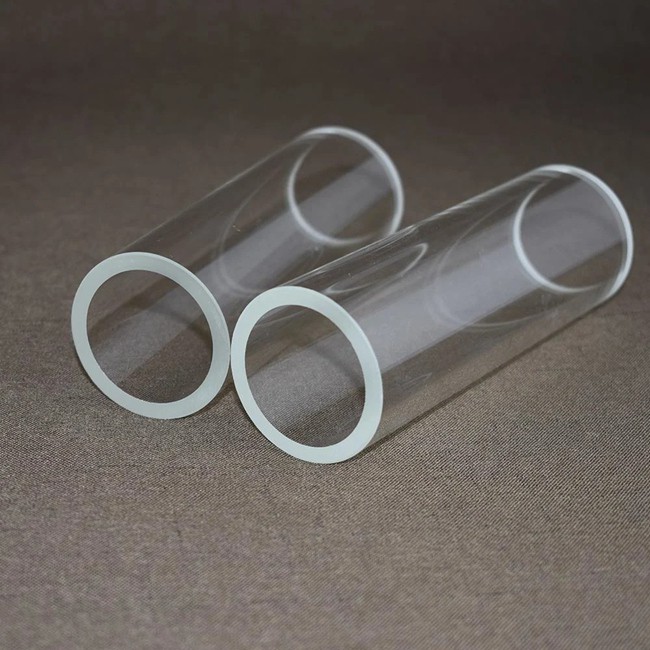

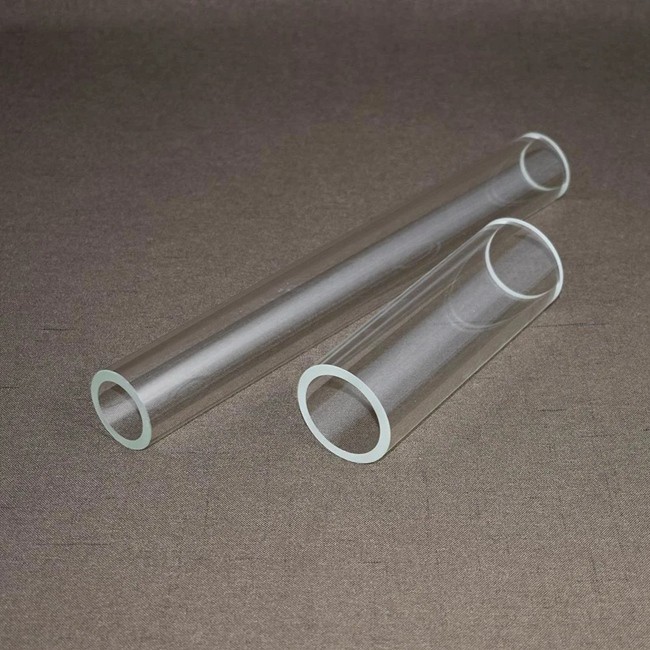

Best Price Large Diameter Clear Quartz Furnace Tube for Lab Test

Product description

Quartz glass tubes are used in the manufacture of halogen, mercury, and xenon lamps, which are commonly used in lighting, stage lighting, and other fields. Due to its high temperature resistance properties, it is used in the manufacture of various heaters such as infrared heaters and ultraviolet heaters. In the laboratory, it is commonly used in tube furnaces, chemical reactors, quartz bet sample tubes and other equipment for high temperature experiments and chemical reactions. As a container for epitaxy, diffusion, oxidation, etc. in the semiconductor production process. Used in ovens, drying equipment, etc., as well as some occasions that require corrosion resistance and high temperature resistance. Daily life such as aquarium heaters, quartz tube foot warmers and so on.

The softening point temperature of quartz glass is about 1730°C. It can be used for a long time at 1100°C, and the maximum temperature for a short time can be up to 1450°C. In addition to hydrofluoric acid, quartz glass almost no chemical reaction with other acids, and its acid resistance is 30 times that of ceramics, 150 times that of stainless steel, especially at high temperatures, the chemical stability of any other engineering materials are incomparable. The thermal expansion coefficient of quartz glass is extremely small, can withstand drastic temperature changes, the quartz glass will be heated to about 1100 ℃, into the room temperature water will not blow up.

Large diameter glass tubes are relatively fragile, so violent collision and excessive stress concentration should be avoided during transportation, installation and use to ensure their safety and service life. Large diameter glass tube plays an important role in many fields with its unique physical and chemical properties. With the continuous progress of technology and the expansion of application fields, the market prospect of large diameter glass tube will be broader.

The production process of large diameter glass tubes mainly includes batching, melting, forming and annealing. Among them, the forming process is particularly critical, usually using mechanical forming methods such as centrifugal casting, where the molten glass is injected into a high-speed rotating mold, the centrifugal force is used to make the glass cling to the mold wall, and the rotation continues until the glass hardens. This method is capable of producing large diameter, high quality glass tubes.

Large diameter glass tubes are widely used for the storage and transfer of high-viscosity, high-density substances. Its inner wall is smooth and easy to clean and sterilize, making it an ideal packaging material for substances. In industrial production, large diameter glass tubes can be used in separation, reaction and heat transfer devices to meet various process requirements. In architectural design, large diameter glass tube can be used in the design and construction of new energy sources such as solar energy and geothermal energy to improve the efficiency of energy utilization.

Recommended products