China Factory Price Electric Gas Pressure Metal Fast Vacuum Heat Treatment Sintering Furnace

Product description

The working principle of electric sintering furnace is mainly based on electric heating technology. It uses heating elements such as resistance wires, silicon carbide rods, or electromagnetic induction to convert electrical energy into thermal energy and heat the materials inside the furnace. As the temperature increases, the atoms or molecules inside the material begin to move more vigorously, gradually reaching the temperature required for sintering, and then undergoing physical or chemical changes such as densification and grain growth, ultimately forming the desired product.

An electric sintering furnace is a device that uses electrical energy to heat materials and cause physical or chemical changes at high temperatures, thereby achieving the purpose of sintering. Electric sintering furnace is an important material processing equipment with a wide range of application fields and significant economic value. During use, it is necessary to pay attention to safe operation and regular maintenance to ensure its normal operation and extend its service life.

The application range of sintering furnace is very wide, mainly including:

Ceramic field: used for sintering ceramic powders, ceramic inserts, and other zirconia ceramics.

Powder metallurgy field: used for producing various powder metallurgy mechanical parts, such as gears, bearings, etc.

In the field of solar energy, polycrystalline silicon ingot furnace is also a type of sintering furnace used for the manufacturing of solar cells.

Other fields: such as sintering of diamond saw blades, heat treatment of copper, annealing of steel strips, etc.

Usage and maintenance

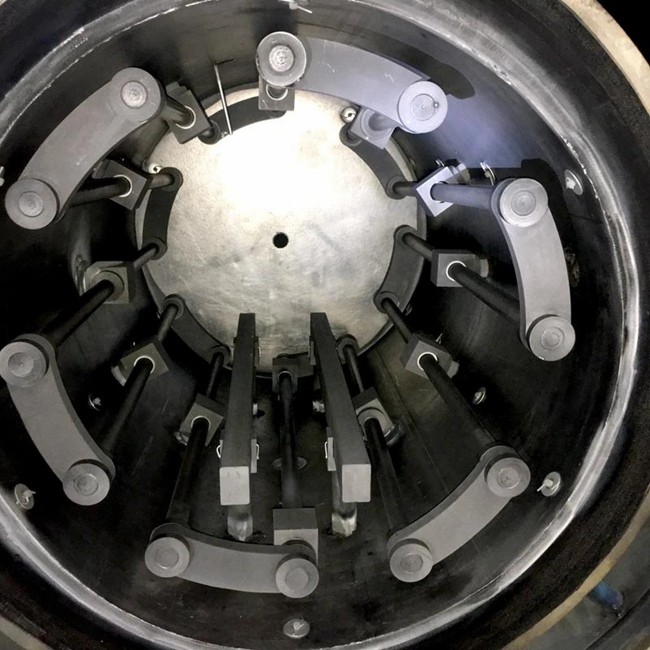

When using a sintering furnace, it is necessary to strictly control the temperature and sintering time to ensure the quality and performance of the material. At the same time, the design and manufacturing of sintering furnaces also need to consider special processing requirements, such as corrosion resistance, compression resistance, and good thermal stability. In order to maintain the good performance and extend the service life of the sintering furnace, regular maintenance and upkeep are also necessary, including cleaning the interior of the furnace, inspecting heating elements, replacing worn parts, etc.

Recommended products