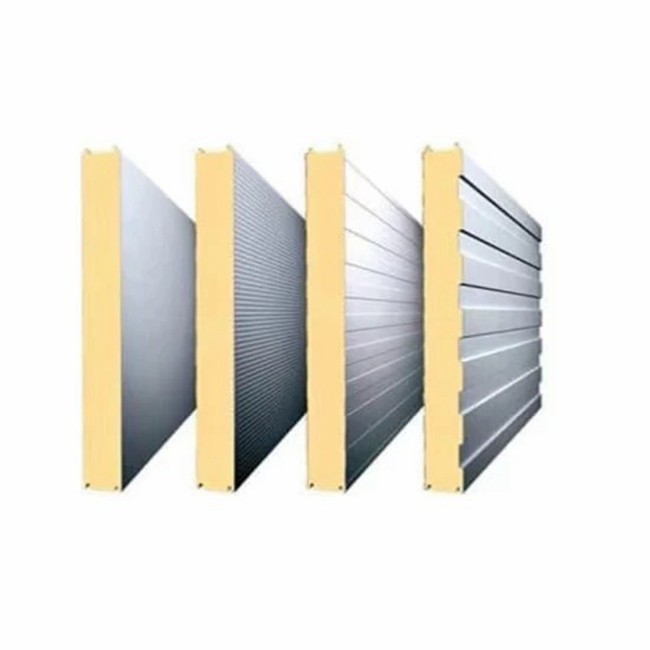

High Quality Decorative PU/Rockwool Foam Sandwich Board Insulation Protection Aluminum Composite Metal Carving Exterior Wall Panel

Product description

Aluminum composite sandwich honeycomb panel by the upper and lower layers of aluminum and the middle of the honeycomb aluminum core through a special bonding technology composite. The surface aluminum plate is usually 0.5mm to 1.5mm thickness of aluminum alloy sheet, with good fire, weather and corrosion resistance. The intermediate honeycomb aluminum core consists of many hexagonal aluminum honeycomb holes parallel to each other, which not only reduce the overall weight but also enhance the stability and rigidity of the structure. The bonding layer uses a high-strength adhesive or adhesive film to firmly bond the surface aluminum panel and the honeycomb aluminum core together to form a whole.

Aluminum sandwich panels are prepared by various methods, including adhesive connection method, laser welding connection method, sewing connection method and so on. Among them, the adhesive connection method is a simple and convenient method, but there are lower strength and easy delamination under high temperature and corrosive conditions to destroy the shortcomings; laser welding connection method is a complex process, the production time is longer; stitching connection method is a complex production process and the strength of the connection is low.

Recommended products