China Factory Price Electric Gas Pressure Metal Fast Vacuum Heat Treatment Sintering Furnace

Product description

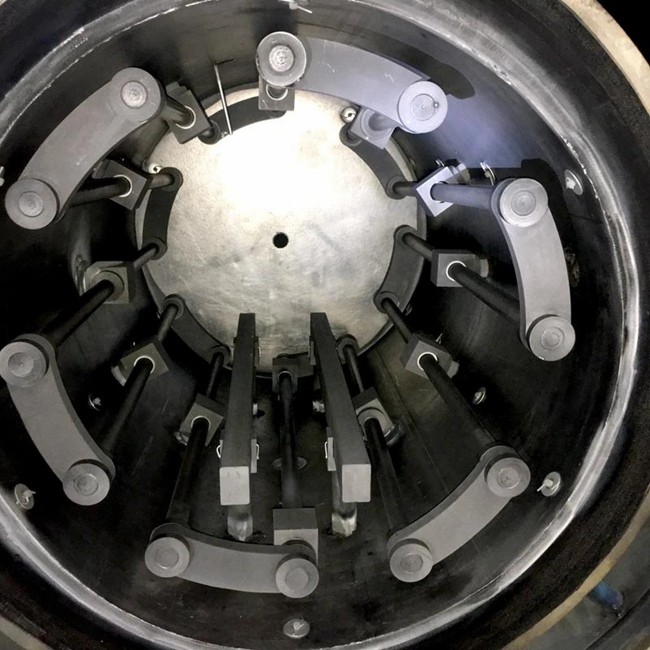

Electric sintering furnaces can be classified into various types based on their heating methods, structural forms, and application fields. For example, a vacuum induction sintering furnace is a device that uses the principle of medium frequency induction heating to sinter materials under vacuum or protective atmosphere conditions. It has the advantages of fast heating speed, good temperature uniformity, and high sintering quality, and is particularly suitable for industrial production of hard alloys, dysprosium metal, ceramic materials, etc.

The working principle of electric sintering furnace is mainly based on electric heating technology. It uses heating elements such as resistance wires, silicon carbide rods, or electromagnetic induction to convert electrical energy into thermal energy and heat the materials inside the furnace. As the temperature increases, the atoms or molecules inside the material begin to move more vigorously, gradually reaching the temperature required for sintering, and then undergoing physical or chemical changes such as densification and grain growth, ultimately forming the desired product.

The vacuum sintering furnace can provide a high-temperature and high vacuum environment, ensuring that materials undergo heat treatment under oxygen free and impurity free conditions, effectively preventing surface oxidation of materials and contamination by gas impurities, and ensuring the purity and quality of materials. The vacuum sintering furnace has the characteristic of good high-temperature uniformity, which can make the temperature distribution of the material uniform throughout the sintering process, ensuring the stability and consistency of the sintering effect.

There are various heating methods for vacuum sintering furnaces, mainly including resistance heating, induction heating (such as power frequency, medium frequency, high frequency induction heating), and microwave heating. Among them, induction heating is a commonly used heating method in vacuum sintering furnaces, which uses the principle of electromagnetic induction to generate eddy currents inside the material, thereby achieving rapid heating. The vacuum sintering furnace adopts efficient heating methods such as induction heating, with fast heating speed, which can improve production efficiency. The vacuum sintering furnace can reduce energy consumption and exhaust emissions during the heating process, which meets the energy-saving and environmental protection requirements of modern industry.

Recommended products