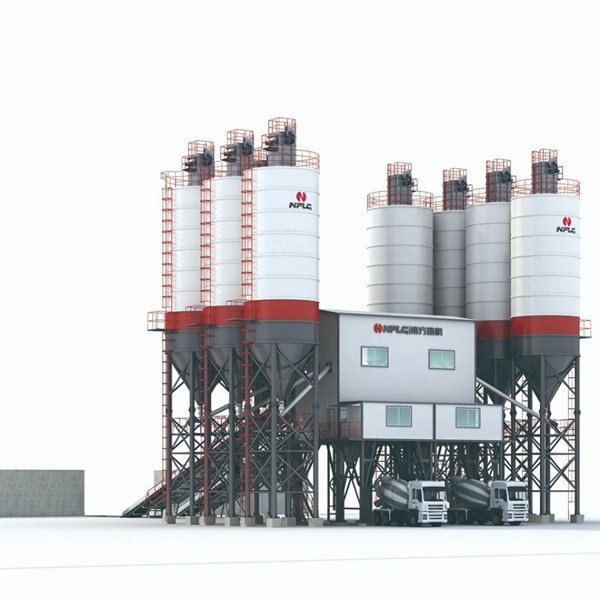

China Factory Fixed Cement Concrete Concrete Batching Mixing Plant Stationary Machine Manufacturers for Sale

Product description

Concrete is a composite material composed of cement, aggregates (such as sand and gravel), water, and sometimes additives, and is the cornerstone of buildings. Its versatility, strength, and durability make it an important component of the construction process. Concrete mixing plants, also known as batching plants, are the core of producing this important material. They aim to mass produce concrete and ensure a stable supply of high-quality concrete for construction projects of all scales.

Working steps of concrete mixing plant

1. Aggregate handling: The first step involves the handling and storage of aggregates. These materials are usually stored in silos or hoppers and measured by weight or volume.

2. Cement treatment: Cement is a binder in concrete, stored in silos, and measured according to the formula of the concrete mixture.

3. Mixing: Then transport the aggregate and cement to the mixer, where they are mixed with water and any necessary additives. The mixing process ensures that all components are thoroughly mixed to obtain a consistent high-quality concrete mixture.

4. Unloading: After mixing the concrete to the desired consistency, it is unloaded into a truck mixer or truck and transported to the construction site.

The working principle of a concrete mixing plant is to mix raw materials such as cement, sand, and stones in a certain proportion into a mixer, and add an appropriate amount of water during the mixing process to achieve the ideal pouring state of the concrete. The mixer thoroughly mixes the raw materials by rotating the mixing blades, ensuring the uniformity and stability of the concrete. Fixed mixing plants and mobile mixing plants. The fixed mixing plant is installed in a fixed location, with strong production capacity and stable operation; The mobile mixing plant is pulled by a trailer unit, which has good maneuverability and is suitable for various small and medium-sized temporary construction projects.

The concrete mixing plant mainly consists of the following five systems and other ancillary facilities:

Mixing host: It is the core equipment of a concrete mixing plant, responsible for mixing and blending various raw materials.

Material weighing system: used for precise weighing of various raw materials to ensure the accuracy of concrete mix proportions.

Material conveying system: responsible for conveying various raw materials to the mixing host.

Material storage system: used for storing raw materials such as cement, sand, stone, etc.

Control system: Automatically control the entire mixing plant to ensure the smooth progress of the production process.

Recommended products