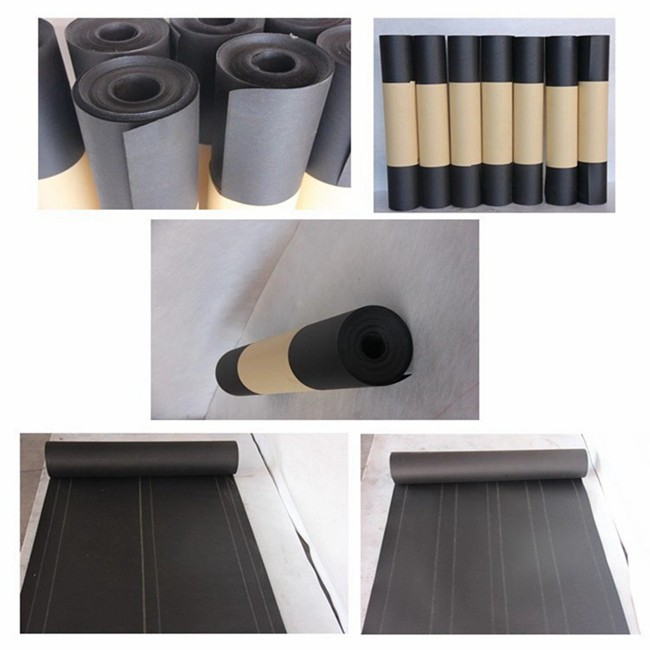

Factory Sypplier Wooden Roofing Materials Black Asphalt Tar Paper

Product description

Construction asphalt felt paper is a building material made from animal hair or plant fibers, which is soaked in asphalt and made from felt or thick paper blanks. It has the characteristics of impermeability and toughness, and is usually used as a waterproof and moisture-proof layer for roofs, foundations, basement walls, etc. Oil felt paper is also a general term for asphalt waterproofing membranes, which can be made into various types and specifications of products according to different materials and processes.

Performance characteristics

Excellent waterproof performance: Due to the excellent waterproof properties of asphalt, asphalt glass cloth felt can effectively prevent water infiltration and protect buildings from water damage.

Corrosion resistance: Glass fiber and asphalt both have good corrosion resistance, which can resist the erosion of various chemicals and extend the service life of materials.

High temperature resistance: Asphalt can still maintain good stability at high temperatures, so asphalt glass cloth felt also has high temperature resistance and is suitable for waterproofing projects in some high-temperature environments.

High strength: The addition of glass fiber significantly improves the strength of the material, enabling it to withstand certain external forces and impacts.

The leakage of asphalt glass cloth and felt mainly occurs at the through wall pipe, bolt, deformation joint, and roll joint. These special areas have poor waterproof base treatment, loose structure, and loose leveling layer closure; The edge of the additional layer of the coil is not tightly closed, and the cutting of the coil is irregular; Poor twisting and compression of the deformation joint waterproof strip, structural deformation, and other reasons cause water leakage at the deformation joint; The joint rolls constructed successively at the joint of asphalt glass cloth and asphalt felt have been damaged, and the adhesion is not tight, resulting in water leakage. During construction, standardized treatment methods should be adopted according to different special parts. During operation, the roll material should be carefully cut according to its shape, and the edges should be flattened and tightly bonded. After completing the additional layer paving in these parts, careful inspection should be carried out to ensure strict acceptance.

Asphalt glass cloth and felt combine the characteristics of glass fiber and asphalt, and have excellent waterproof, moisture-proof, corrosion-resistant, high-temperature and other properties. Asphalt glass cloth felt is mainly composed of glass fibers and asphalt. Glass fiber, as a reinforcing material, provides the strength and stability of the material; And asphalt serves as a binder and waterproof layer, ensuring the waterproof performance of the material.

The reason for the occurrence of hollowing in asphalt glass cloth and felt is often due to the high moisture content of the base layer of the membrane waterproof layer. Before the leveling layer is dried, the membrane waterproof layer is constructed to seal the moisture inside, and when exposed to hot gas, the waterproof layer swells up; When laying different types of oil felt rolls, if the pressure is not tight and the adhesion is not dense, the hot air generated during the operation will be trapped, causing the rolls to bubble and bulge. During construction, attention should be paid to the dryness of the base layer. During operation, it should be compacted and tightly adhered, and no gas should be trapped to prevent hollowing.

Recommended products