New Design High Temperature Industrial Oven Powder Metallurgy Heat Treatment Vacuum Sintering Furnace

Product description

Electric sintering furnaces are widely used in various fields. In the metallurgical industry, it is mainly used to manufacture metal materials such as iron and steel. Through sintering treatment, the original ore is transformed into block like material, which is convenient for subsequent processing and utilization; In the chemical industry, sintering furnaces can be used to manufacture raw materials for various chemicals; In the building materials industry, it is applied in the production of materials such as cement and ceramics; In the ceramic industry, sintering furnaces are used to produce various ceramic products. In addition, with the continuous development of technology, the application of electric sintering furnaces in new energy, aerospace and other fields is becoming increasingly widespread.

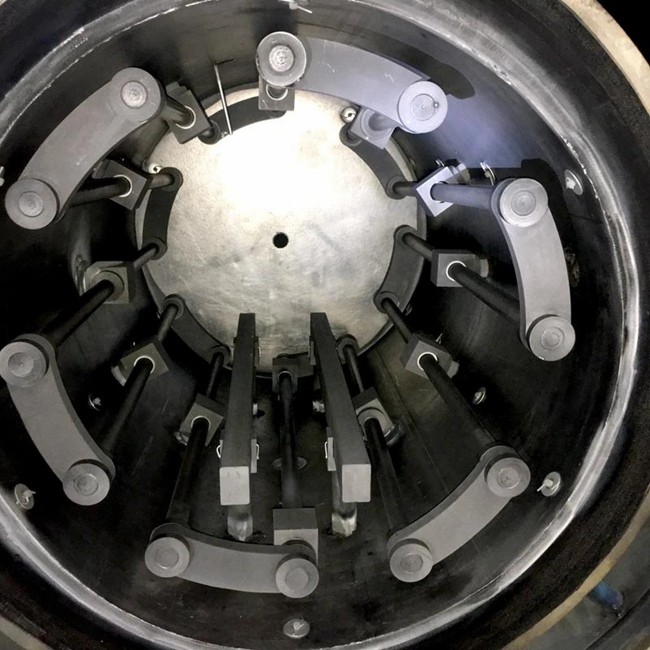

Electric sintering furnaces can be classified into various types based on their heating methods, structural forms, and application fields. For example, a vacuum induction sintering furnace is a device that uses the principle of medium frequency induction heating to sinter materials under vacuum or protective atmosphere conditions. It has the advantages of fast heating speed, good temperature uniformity, and high sintering quality, and is particularly suitable for industrial production of hard alloys, dysprosium metal, ceramic materials, etc.

The working principle of electric sintering furnace is mainly based on electric heating technology. It uses heating elements such as resistance wires, silicon carbide rods, or electromagnetic induction to convert electrical energy into thermal energy and heat the materials inside the furnace. As the temperature increases, the atoms or molecules inside the material begin to move more vigorously, gradually reaching the temperature required for sintering, and then undergoing physical or chemical changes such as densification and grain growth, ultimately forming the desired product.

The vacuum sintering furnace can provide a high-temperature and high vacuum environment, ensuring that materials undergo heat treatment under oxygen free and impurity free conditions, effectively preventing surface oxidation of materials and contamination by gas impurities, and ensuring the purity and quality of materials. The vacuum sintering furnace has the characteristic of good high-temperature uniformity, which can make the temperature distribution of the material uniform throughout the sintering process, ensuring the stability and consistency of the sintering effect.

Usage and maintenance

When using a sintering furnace, it is necessary to strictly control the temperature and sintering time to ensure the quality and performance of the material. At the same time, the design and manufacturing of sintering furnaces also need to consider special processing requirements, such as corrosion resistance, compression resistance, and good thermal stability. In order to maintain the good performance and extend the service life of the sintering furnace, regular maintenance and upkeep are also necessary, including cleaning the interior of the furnace, inspecting heating elements, replacing worn parts, etc.

Recommended products