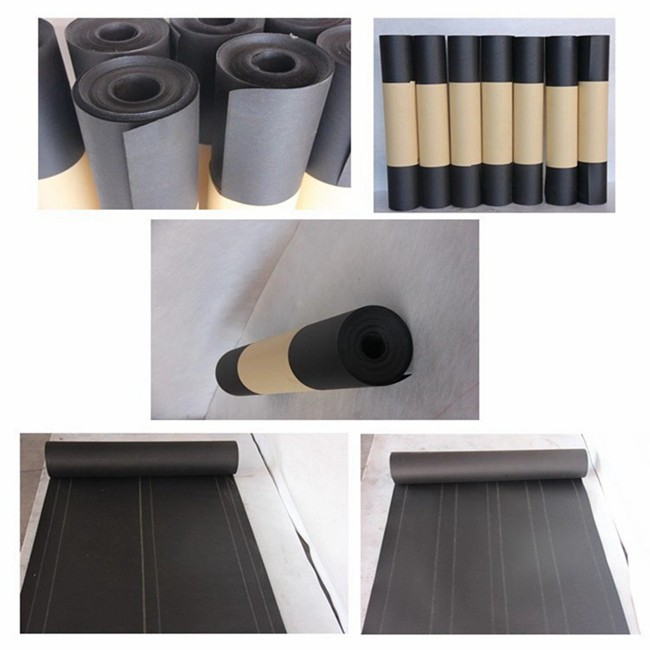

High Quality Bitumen Roofing Felt Paper with Enhanced Weather Resistance

Product description

Asphalt felt paper is mainly used as an isolation layer and temporary protective layer material in waterproof construction to prevent damage to the finished waterproof layer during construction. It is widely used for waterproofing and moisture-proof treatment of roofs, basements, walls, floors and other parts. In addition, oil felt paper can also be used for moisture-proof protection of pipe galleries, packaging materials, and the lower layer of multi-layer waterproof layers. Oil felt paper should be stored in a dry and ventilated environment, avoiding direct sunlight and rain. During transportation and storage, care should be taken to prevent damage or deformation.

The production process of asphalt felt paper mainly includes preparing raw materials (such as asphalt, paper, accelerators, stabilizers, etc.), operating equipment (such as asphalt melting pot, coating mixer, rolling mill, etc.), and specific process flow. During the production process, various raw materials are mixed in proportion, stirred evenly by a mixer, and then pressed into rolls or processed into felt paper of the required thickness by a rolling mill. Subsequently, the oil felt paper is subjected to heating, embossing, and other treatments to increase its anti slip performance and aesthetic appeal. Finally, the processed felt paper is cut and packaged to complete the production process.

The leakage of asphalt glass cloth and felt mainly occurs at the through wall pipe, bolt, deformation joint, and roll joint. These special areas have poor waterproof base treatment, loose structure, and loose leveling layer closure; The edge of the additional layer of the coil is not tightly closed, and the cutting of the coil is irregular; Poor twisting and compression of the deformation joint waterproof strip, structural deformation, and other reasons cause water leakage at the deformation joint; The joint rolls constructed successively at the joint of asphalt glass cloth and asphalt felt have been damaged, and the adhesion is not tight, resulting in water leakage. During construction, standardized treatment methods should be adopted according to different special parts. During operation, the roll material should be carefully cut according to its shape, and the edges should be flattened and tightly bonded. After completing the additional layer paving in these parts, careful inspection should be carried out to ensure strict acceptance.

Asphalt glass cloth and felt combine the characteristics of glass fiber and asphalt, and have excellent waterproof, moisture-proof, corrosion-resistant, high-temperature and other properties. Asphalt glass cloth felt is mainly composed of glass fibers and asphalt. Glass fiber, as a reinforcing material, provides the strength and stability of the material; And asphalt serves as a binder and waterproof layer, ensuring the waterproof performance of the material.

Recommended products