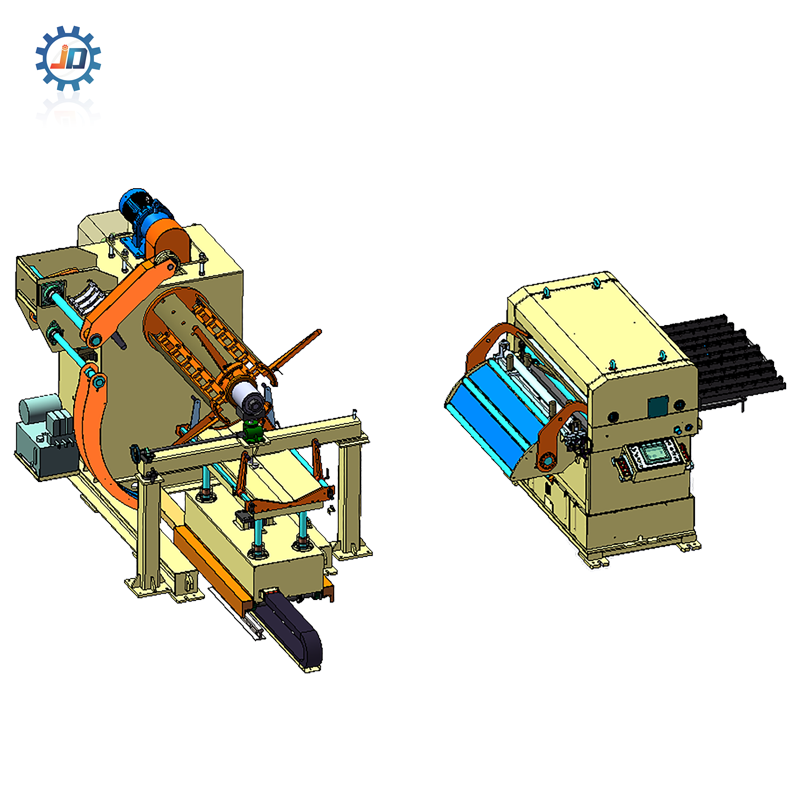

High-Precision 3 in 1 Decoiler Straightener Feeder for Press Machine/Slitting Machine/cutting machine

Product description

| Model | JDA3-400B | JDA3-500B | JDA3-600B | JDA3-800B |

| Width of Material (mm) | 50-400 | 50-500 | 50-600 | 50-800 |

| Thickness of Material (mm) | 0.8-4.5mm | |||

| Straightening Roller(Pcs) | Up 4/ Down 3 | |||

| Feed Roller | 2 sets | |||

| Feed Line Height | ±100mm&Accoring to customers’ Requirements | |||

| Coil Weight (T) | 2T | 3T | 3T | 5T |

| Coil I.D.(mm) | 450-530mm | |||

| Coil O.D.(mm) | 1200mm | |||

| Feeding Speed (m/min) | 16m/Min | |||

| Feed Accuracy | ±0.1/100mm | |||

| Maximum Feeding Length(mm) | 950-1200mm (Can be customized according to customer requirements) | |||

| Machine Weight (kg) | 2000kg | 2300kg | 2600kg | 3000kg |

| Power Supply | 220V&380V | |||

| Uncoil Expansion | Hydraulic Expansion | |||

| Machine dimensions(mm) | 3600*1600*1900mm | 3600*1600*1900mm | 3600*1600*1900mm | 3600*1600*1900mm |

| Air Pressure | 0.5 | |||

| Uncoil Motor (Kw) | AC2.9KW | AC2.9KW | AC4.4KW | AC4.4KW |

| Feeder Power(Kw) | AC 2.2Kw | AC 2.2Kw | AC 3.7Kw | AC3.7Kw |

| Control System | PLC+touch Screen | |||

Standard Configuration:

Photoelectric arc control system

Feed outlet guide rack device

Press arm device

The feeding line height is adjusted by screw worm gear

Dial indicator

Arc control roller

The rack contains air pressure disc brake device

Rack variable frequency speed regulation

Optional Configuration

Feed line height electric adjustment device

Hydraulic automatic loading trolley

| Type | JDA3-400B | JDA3-600B | JDA3-800B | JDA3-1000B | |

| Feeding Thickness of Plating(mm) | 0.6-0.8mm | 400 | 600 | 800 | 1000 |

| 1mm | 400 | 600 | 800 | 750 | |

| 1.2mm | 400 | 600 | 700 | 600 | |

| 1.6mm | 400 | 590 | 480 | 430 | |

| 1.8mm | 400 | 500 | 420 | 380 | |

| 2mm | 400 | 430 | 370 | 330 | |

| 2.3mm | 400 | 360 | 320 | 290 | |

| 2.8mm | 370 | 290 | 250 | 230 | |

| 3.2mm | 300 | 250 | 220 | 200 | |

| 4.5mm | 160 | 160 | 150 | 110 | |

Warranty And Service:

▼ One year warranty for whole feeder/uncoiler/straightener machine.

▼ All spare parts are available as most of the parts produced by our factory, and the most preferential price of the required parts would be provided after warranty as we promise to provide life-long service for customer.

▼ It is easy to get the electric parts as all are international famous brands.

▼ We can provide technical training and consulting via email, phone or video.

▼ We can send out engineers for service, installation or training with reasonable additional cost.

▼ English operation and maintenance manual is provided with feeder/uncoiler/straightener machine.

Recommended products