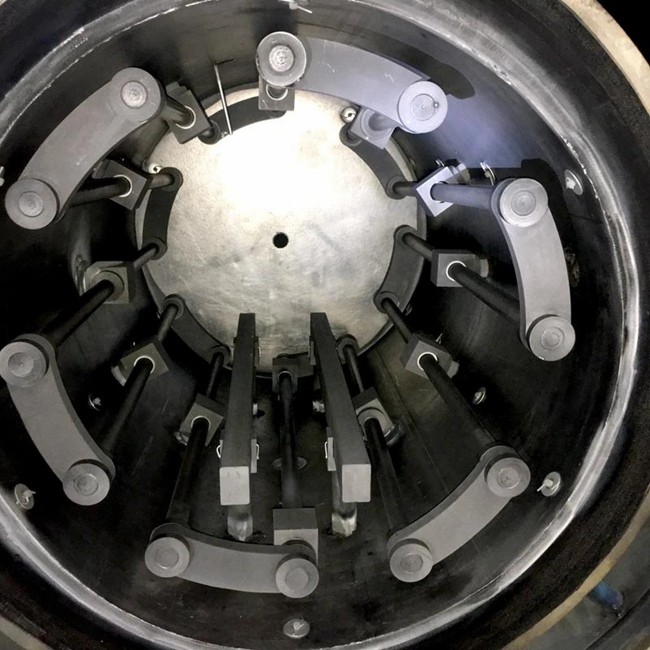

New Design Electric Gas Pressure Metal Fast Vacuum Heat Treatment Sintering Furnace

Product description

Electric sintering furnaces are widely used in various fields. In the metallurgical industry, it is mainly used to manufacture metal materials such as iron and steel. Through sintering treatment, the original ore is transformed into block like material, which is convenient for subsequent processing and utilization; In the chemical industry, sintering furnaces can be used to manufacture raw materials for various chemicals; In the building materials industry, it is applied in the production of materials such as cement and ceramics; In the ceramic industry, sintering furnaces are used to produce various ceramic products. In addition, with the continuous development of technology, the application of electric sintering furnaces in new energy, aerospace and other fields is becoming increasingly widespread.

An electric sintering furnace is a device that uses electrical energy to heat materials and cause physical or chemical changes at high temperatures, thereby achieving the purpose of sintering. Electric sintering furnace is an important material processing equipment with a wide range of application fields and significant economic value. During use, it is necessary to pay attention to safe operation and regular maintenance to ensure its normal operation and extend its service life.

The application range of sintering furnace is very wide, mainly including:

Ceramic field: used for sintering ceramic powders, ceramic inserts, and other zirconia ceramics.

Powder metallurgy field: used for producing various powder metallurgy mechanical parts, such as gears, bearings, etc.

In the field of solar energy, polycrystalline silicon ingot furnace is also a type of sintering furnace used for the manufacturing of solar cells.

Other fields: such as sintering of diamond saw blades, heat treatment of copper, annealing of steel strips, etc.

Sintering furnace is an important material processing equipment, mainly used to heat powdered or other forms of raw materials to a molten or semi molten state through high temperature, and then cool and solidify them to obtain solid blocks with certain strength and density. This device has wide applications in various fields such as ceramics, metals, and glass, and is one of the important tools for preparing these materials.

Recommended products