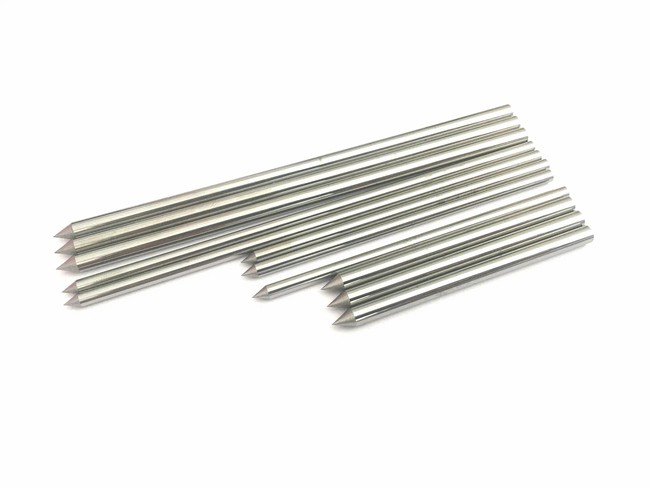

China Manufacturer Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod

Product description

Hard alloy rods are key materials for manufacturing various cutting tools such as turning tools, milling cutters, planers, drills, boring tools, etc. These cutting tools are widely used in industries such as metal processing, wood processing, and plastic processing to efficiently and accurately cut various materials. Hard alloy rods can be used to manufacture molds, such as stamping molds, extrusion molds, and injection molds. Due to its high hardness and wear resistance, hard alloy molds can withstand high pressure and frequent impacts, extending the service life of the molds.

Tungsten rods use special high-temperature powder metallurgy technology to compress and sinter metal powder at high temperatures. Low coefficient of thermal expansion: In high-temperature environments, the thermal expansion coefficient of tungsten alloy rods is relatively low, which helps to maintain the dimensional stability of the material. Tungsten rods have good thermal conductivity, which helps with rapid heat transfer and dispersion. Tungsten is one of the metals with extremely high melting points, which enables tungsten alloy rods to maintain stable performance even in high temperature environments.

Recommended products