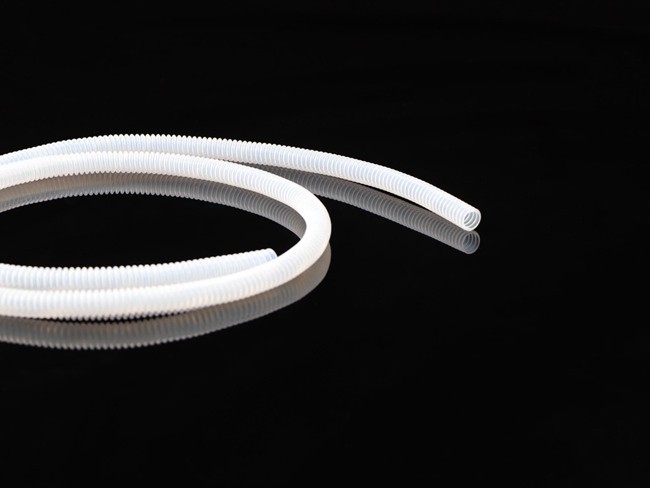

High Quality Industrial Grade Wear Resistant Plastic Pipe

Product description

Attention

Select appropriate hose materials and specifications based on specific usage environments and requirements.

Avoid excessive bending and twisting of the hose during use to prevent damage to its structure and performance.

Regularly check the connection and sealing of the hose to ensure no leakage or looseness.

Avoid exposing the hose to high temperatures, strong radiation, and corrosive environments to prevent accelerated aging and damage of the hose.

Application fields of PTFE hoses

Chemical industry: used for transporting corrosive media such as acids, alkalis, salts, etc.

Oil and gas industry: used for transporting high-pressure media such as oil and liquid petroleum gas.

Food and pharmaceutical industry: meets hygiene requirements and can be used to transport high-pressure liquids such as food, beverages, and pharmaceuticals.

Aerospace field: used for pipeline connection and sealing of aircraft hydraulic systems, pneumatic systems, etc.

Automotive industry: used for connecting and sealing pipelines in engine lubrication systems, braking systems, etc.

The manufacturing process of PTFE hoses mainly includes steps such as raw material preparation, extrusion molding, cooling and shaping, cutting and processing, finished product inspection, and packaging and warehousing. High purity polytetrafluoroethylene resin is selected as the raw material, dried for later use, and processed into tubular blanks through extrusion molding and cooling shaping processes. After cutting and finished product inspection, qualified finished products are packaged and stored.

PTFE hose is a high-performance pipeline material with various excellent performance characteristics, widely used in multiple industries. The inner wall of PTFE hose is very smooth, with low friction coefficient, which can effectively protect the conveying medium and reduce conveying resistance. PTFE hoses also have good electrical insulation properties. PTFE hose also has good radiation resistance and aging resistance, and can maintain stable performance in extreme environments.

PTFE hoses have excellent chemical stability and are almost not corroded by any chemical substances. They can resist corrosive media such as acids, alkalis, and salts, and are therefore widely used in various highly corrosive environments. PTFE hoses can be used over a wide temperature range, with high temperature resistance up to 260 ℃, and can also be used in low temperature environments up to -250 ℃ without brittleness or aging.

Recommended products