Wholesale price Industrial Rubber Timing Belt Htd

Product description

Rubber synchronous belts are widely used in applications that require high-speed, high load, and high-precision transmission, such as automobiles, textiles, machine tools, office machinery, power tools, instruments, and food packaging machinery, due to their high precision, high stability, and wear resistance. In addition to its structural and transmission characteristics, it also has good dynamic flexibility, good crack resistance, excellent ozone performance, aging resistance, heat resistance, oil resistance, wear resistance and other features. These characteristics enable rubber synchronous belts to maintain good performance even in complex environments.

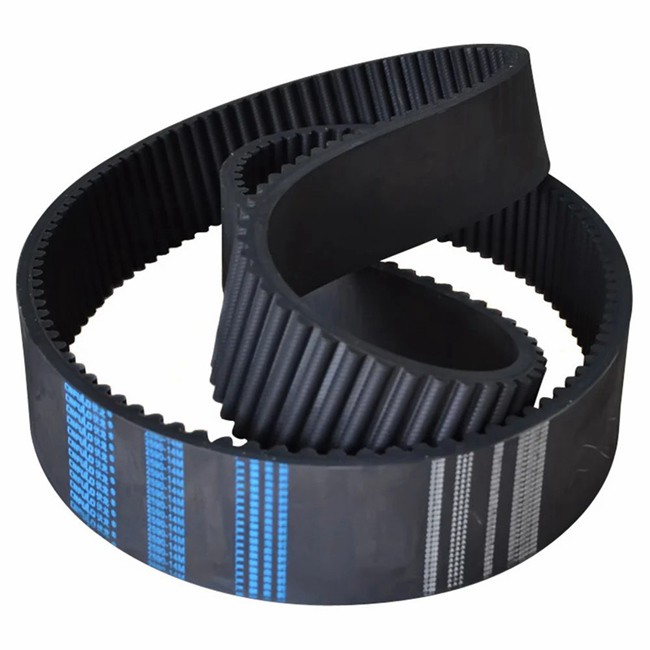

Synchronous belt is a transmission component that combines the advantages of high efficiency, precision, wear resistance, and low noise, and plays an important role in modern mechanical transmission systems. When the power source drives the driving wheel to rotate, the teeth on the driving wheel interlock with the teeth on the synchronous belt. Due to the precise matching of tooth profile and spacing, relative sliding does not occur during the transmission process, thus achieving synchronous motion.

Synchronous belt, also known as toothed belt or gear belt, is an efficient and precise transmission component widely used in various mechanical and industrial fields. A synchronous belt is composed of an annular belt with equidistant teeth on its inner surface and a matching pulley with corresponding teeth. It utilizes the meshing transmission between belt teeth to achieve the transmission of power and motion.

Rubber synchronous belts play a crucial role in automotive engines, used to drive auxiliary equipment such as generators, water pumps, and air conditioning compressors, ensuring accurate synchronization between the engine's valves and pistons. In industrial machinery such as high-speed packaging machines, printing equipment, and paper making machinery, rubber synchronous belts are used for transmission and positioning to ensure production efficiency and product quality.

Rubber synchronous belt usually adopts high-quality imported neoprene or polyurethane rubber materials as the matrix, which have good elasticity, wear resistance, oil resistance and aging resistance. The skeleton material of rubber synchronous belts is mostly imported high-quality fiberglass rope, which enhances the tensile strength and stability of the belt body. The toothed surface is often protected with materials such as nylon 66 high elasticity cloth to improve wear resistance and service life.

Recommended products