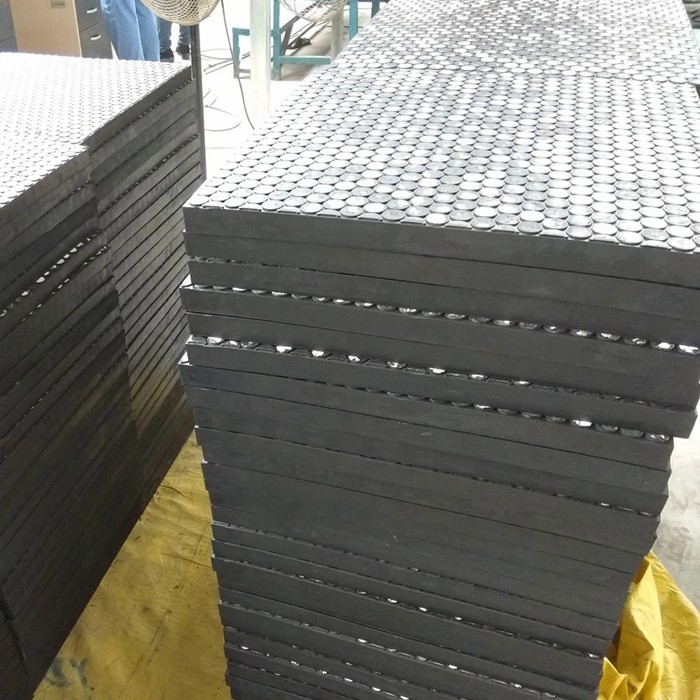

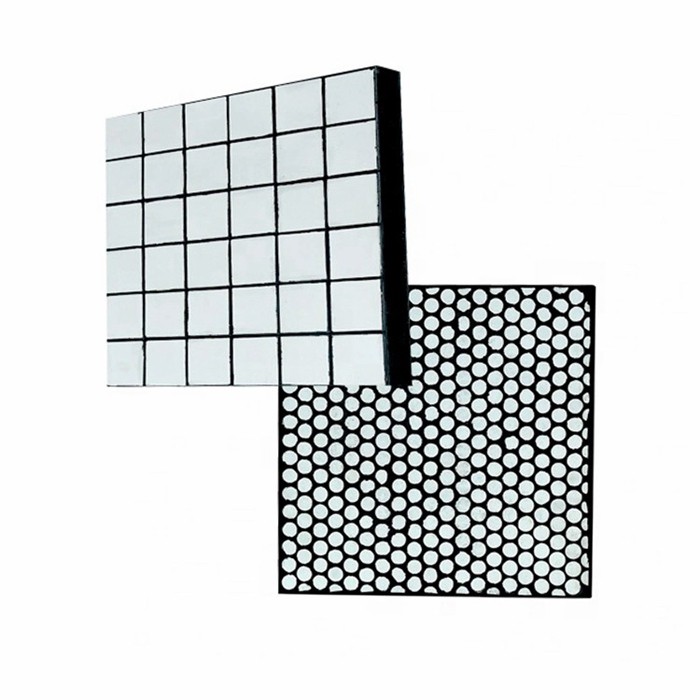

Factory Directly High Alumina Hexagon Lining Ceramic Liner Plate

Product description

Alumina ceramic lining plates are widely used in various industries, especially in situations where wear resistance, high temperature resistance, and corrosion resistance are required. Specifically, it can be used as a lining material to protect parts of equipment from wear and corrosion. For example, in the fields of ore, coal mining, casting, etc., alumina ceramic lining plates can be used for lining grinding machines, conveying systems, furnace temperature control systems, etc. In addition, it is widely used in coal transportation, feeding systems, powder production systems, ash discharge, dust removal systems, and other mechanical equipment with high wear and tear in enterprises such as thermal power, steel, smelting, machinery, coal, mining, chemical, cement, and port terminals.

Aluminum oxide ceramic lining plate has high hardness, which can effectively resist wear and prolong the service life of equipment. It has good resistance to various corrosive media and is suitable for corrosive environments such as chemical engineering. Capable of maintaining stable physical and chemical properties in high-temperature environments, suitable for high-temperature working conditions. Aluminum oxide ceramic lining plate can be customized according to the shape of the equipment, with easy installation, saving time and cost.

Aluminum oxide ceramic lining plate has characteristics such as high hardness, high wear resistance, corrosion resistance, and high temperature resistance. These properties enable it to remain stable under harsh working conditions and are not easily worn or corroded. Moreover, it has the advantages of light weight, easy installation, cost savings, improved production efficiency, and environmental protection without pollution, and has a wide range of applications in multiple fields.

Although the initial investment for alumina ceramic lining may be high, its wear resistance, corrosion resistance, and high temperature resistance can significantly extend the service life of equipment, reduce the frequency of replacement and maintenance, and thus save long-term costs. The high wear resistance and corrosion resistance of alumina ceramic lining plate enable the equipment to operate stably under harsh working conditions, reducing downtime and maintenance time, and improving production efficiency. Aluminum oxide ceramic lining plate does not produce harmful substances during use, is environmentally friendly, and meets environmental protection requirements.

Recommended products