Manufacturers Wholesale Competitive Biaxial Geogrid at Competitive Prices

Product description

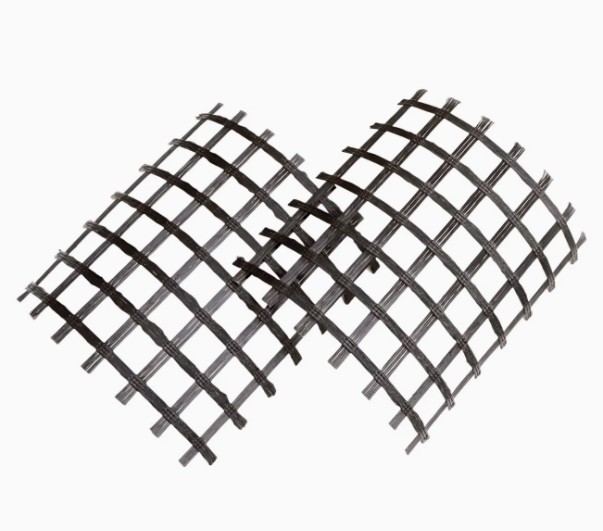

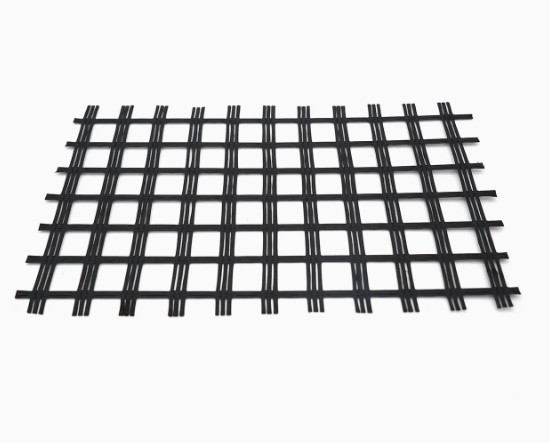

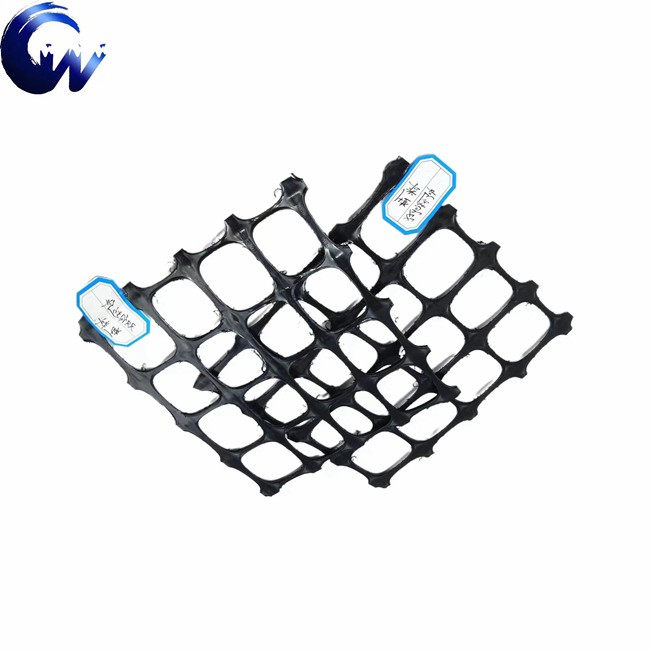

Double axis geogrid is made of high molecular weight polymers (such as polypropylene, polyvinyl chloride, etc.) through extrusion, sheet forming, punching processes, and then longitudinal and transverse stretching. This structure gives it great tensile strength in both longitudinal and transverse directions, providing the soil with an ideal chain system for bearing and spreading forces.

characteristic

High strength: Dual axis geogrids have high biaxial tensile modulus and tensile strength, and can withstand significant external forces.

Good durability: This material has the ability to resist mechanical damage and durability, and can adapt to various harsh environments.

Convenient construction: The double axis geogrid is easy to cut and connect, and the construction is simple and fast, without the need for special construction machinery and professional technicians.

Strong adaptability: Suitable for reinforcing foundations with large load-bearing areas, it can be widely applied in various civil engineering fields.

application area

Reinforcement of embankments and roadbeds: It can enhance the bearing capacity of embankments and roadbeds and extend their service life.

Slope protection: By increasing the shear strength of soil, prevent slope landslides and collapses.

Wall reinforcement: In tunnels and underground engineering, it can enhance the stability of the wall.

Strengthening the bearing foundation of large airports, parking lots, docks, cargo yards, etc.: It can meet the high requirements of these places for the bearing capacity of the foundation.

Construction method

Excavation of foundation bed: excavate the foundation bed according to the design requirements, set up a sand cushion layer, and compact it into a platform.

Laying grid: Lay the biaxial geogrid on the foundation bed according to the design requirements, and the longitudinal axis should be consistent with the main stress direction.

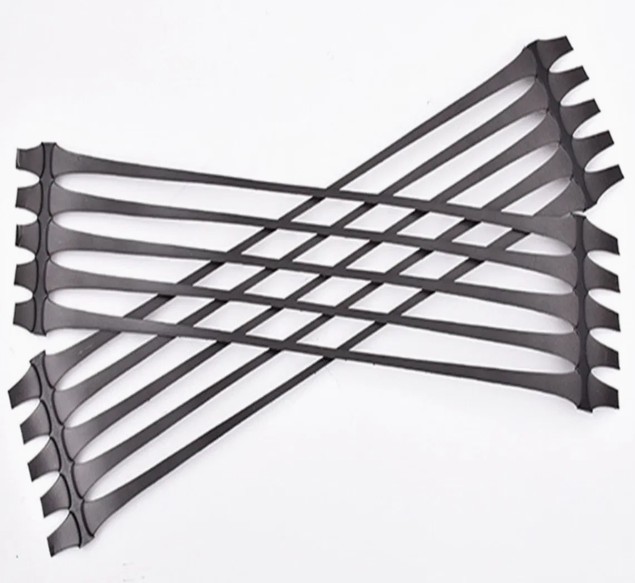

Overlapping and fixing: Grids should be overlapped and tied with plastic tape or fixed to the ground with U-shaped nails.

Backfilling soil material: After laying the grid, the soil material should be backfilled and compacted in a timely manner.

Recommended products