Cold rolled stainless steel strip manufacturers

Product description

Cold-rolled stainless steel strip production process characteristics

Due to the characteristics of stainless steel and the special requirements for product quality, the stainless steel cold rolling production process has the following characteristics:

(1) Stainless steel is a high alloy steel with a large resistance to rolling deformation. In order to carry out high-efficiency and high-precision rolling, a rolling mill with high rigidity should be used, generally a multi-roll cold rolling mill.

(2) Multi-roll cold rolling mills generally adopt a single-machine reversible rolling method. During rolling, the head and tail parts wrapped on the coiler are not rolled and are cut off as scrap. In order to improve the yield rate of the product, a section of lead tape must be welded at both ends of the stainless steel strip before rolling, and the lead tape part is not rolled; in addition, if the quality of the hot-rolled coil is too small, in order to improve the rolling efficiency and yield rate; the small steel coils need to be welded into large steel coils in advance; in the continuous annealing and pickling unit, due to continuous operation, the head and tail connections of the steel strip also need to be welded. Therefore, welding is an indispensable link in the production of stainless steel strips. The welding of stainless steel is much more difficult than that of ordinary steel, especially when the weld needs to be rolled, the requirements for welding quality are more stringent. Therefore, special welding technology is also a feature of cold-rolled stainless steel strip production.

(3) Before cold-rolling of stainless steel strip, the raw material (hot-rolled coil) must be annealed, the intermediate annealing must be performed during the cold rolling process, and the final product must also be annealed. Therefore, annealing is an important link in production. There are many types of stainless steel, and the properties of various steels are different. The purpose, method and requirements of heat treatment are not the same, and there is a unique process system.

(4) The surface quality requirements of cold-rolled stainless steel strip are very strict. Not only are metallurgical defects and processing defects caused by the previous process not allowed to remain, but also obvious defects caused by the cold rolling process are not allowed. To this end, a series of elimination and protection measures are taken during the cold rolling production process. For example, to remove the scale of hot rolling, the hot-rolled steel strip needs to be shot blasted and pickled; to remove the defects caused by the blank and the defects caused by cold rolling and heat treatment, the steel strip is often ground on a grinding unit; to ensure the surface quality after cold rolling, there are very strict requirements for the grinding of the rollers; to prevent scratches on the steel strip during production, the steel coils of each unit are required to be rolled tightly and evenly, and before and after cold rolling, many units need to put protective paper between the layers of the steel coils when winding; in addition, some special protective measures are taken for operations and equipment that are prone to scratches; in order to obtain a good and uniform surface gloss, some finished products need to be pickled after annealing; bright steel plates with special requirements need to be annealed in a protective atmosphere; some products need to be coated on the surface, etc. In short, the production of cold-rolled stainless steel strip is a delicate process that is incomparable to other steel grades.

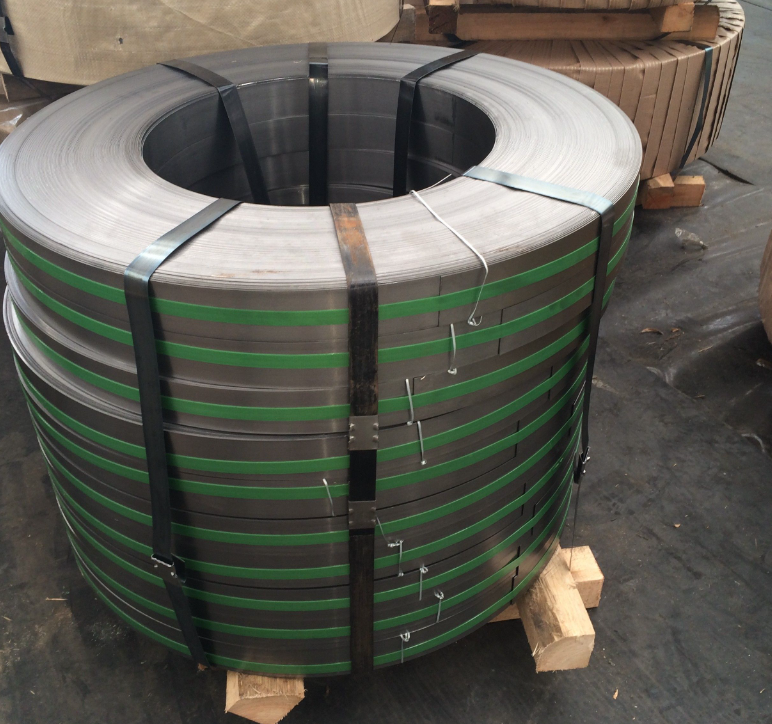

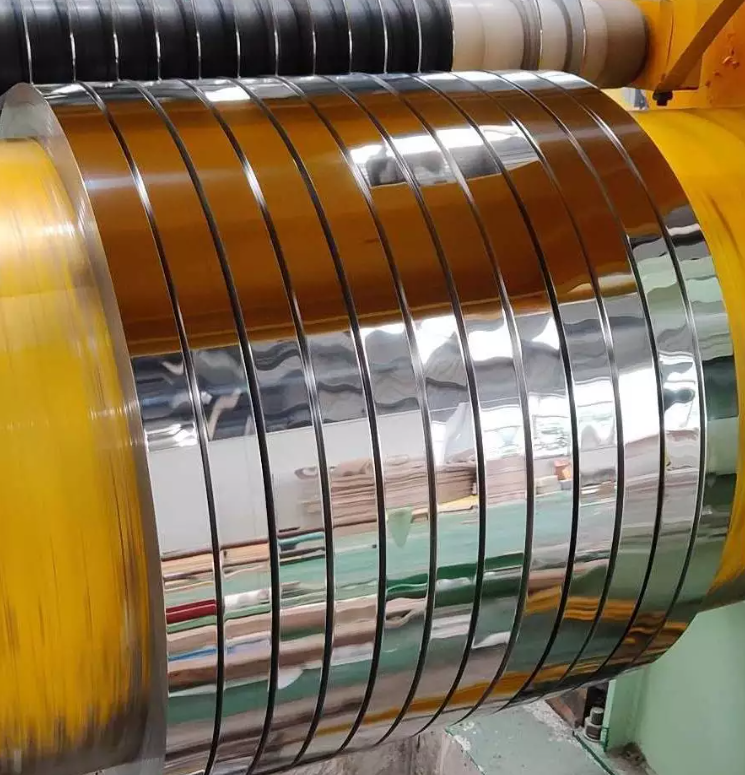

(5) There are some special requirements for the finishing of stainless steel strip. For example, the flattening process not only needs to improve the plate shape, but also needs to use a roller with very low roughness (except for hemp panels) to produce bright 2B steel plates. For ferritic stainless steel, the forming performance of the steel plate must be improved by controlling the flattening amount. Stainless steel is hard and has strict requirements on flatness. It must be straightened with a strong straightening machine, and products of different thicknesses often require different straightening methods. Stainless steel cold-rolled products are usually delivered in two ways: coils and cut plates. Therefore, modern stainless steel cold-rolling plants are equipped with longitudinal cutting units and cross-cutting units.

Cold-rolled stainless steel strip production process

Due to the wide variety of stainless steels, different properties, and very different product quality requirements, the production process of stainless steel cold-rolled steel strips is complex and complicated. The general production process of cold-rolled stainless steel strips is shown in Figure 7-4. For some hot-rolled ferritic and martensitic stainless steels, annealing can be carried out in a continuous furnace, but in practice, the annealing of such steels is usually carried out in a hood annealing furnace in advance. On the hot rolling annealing and pickling unit, only descaling and pickling are performed. The hot rolled austenitic steel coil is annealed and pickled on the unit. Bright annealing is a final annealing method in the cold rolling annealing and pickling process, and is also the product surface processing state required by users - bright heat treatment (surface processing grade NO.9). The bright annealing unit is in the form of horizontal bright annealing unit, vertical bright annealing unit and hood bright annealing furnace. Ferritic and martensitic stainless steel strips are generally annealed in hood bright annealing furnaces.

In order to correct the shape of the steel strip, the finished stainless steel strip should be flattened. Although the shape of the strip is corrected once after flattening, straightening must be performed to produce a completely straight steel strip. Straightening is usually performed on a roller straightener. With the increasing requirements for product flatness, stretch bending straighteners have been greatly developed in recent years. Especially for thin stainless steel strips, the flattening effect is minimal, and the shape correction mainly relies on stretch bending straighteners.

Recommended products