High Thinkness Variable frequency corrector plate automatic decoiler straightener two-in-one

Product description

| Model | GL-200B | GL-300B | GL-400B | GL-500B | GL-600B |

| Width of Material (mm) | 200 | 300 | 400 | 500 | 600 |

| Thickness of Material (mm) | 0.4-3.5mm | ||||

| Coil Weight (Kg) | 800kg | 1000kg | 1500kg | 2000kg | 3000kg |

| Coil I.D.(mm) | 450-530mm | ||||

| Coil O.D.(mm) | 1200mm | ||||

| Straightener Motor(HP) | 2HP | 2HP | 3HP | 3HP | 5HP |

| Reduction Box | |||||

| Feeding Speed (m/min) | 15M/Min | ||||

| Power Supply | AC 3 Phase 380V | ||||

| Feeding Roller | ∅63 UP 2/Down 2 ∅79.5 | ||||

| Straightener Roller | ∅57 Up 3/Down 4 | ||||

| Uncoil Expansion | Hydraulic Expansion | ||||

Features 1.The roller leveling and feeder are placed on the same horizontal platform, which can reduce the high-precision requirements of feeding and leveling errors. It is convenient to install and does not take up space. 2.The roller is made of solid bearing steel, which is heat-treated, hard chrome-plated and then ground. It has high hardness, good wear resistance and long service life. 3.Maintenance and management are simplified, safe and low cost. 4.The control box uses Japanese electronic components, which have few failures and long service life. 5.This machine can use a variable frequency speed regulator for better effect. 6.This machine adopts a one-point down-pressure device, which is an exclusive design. It can adjust the flat point faster and more accurately. It is easy to operate and different from the traditional four-point adjustment. | |||||

| Product Features: 1. The material rack and leveling machine are integrated into one, suitable for various metal coils of 0.4-3.5mm. It adopts an inclined leveling method with high precision and small size, which increases the available space of the factory. 2. The machine has small vibration during operation and stable operation. 3. The material device fastens the material with variable diameter, and there is no damage to the surface of the material during operation. 4. Equipped with an embracing brake device, the tightness can be adjusted, and the material roll rotates more smoothly. 1. The vertical induction bracket is used for induction, which is sensitive, has a wider range of applications, stronger applicability, and better customization, and can meet the needs of different customers. 2. According to the special requirements of customers, it can be designed and equipped with a pressing arm, a frequency converter, a hydraulic expansion device, etc. to increase work efficiency and improve safety. 3. The maximum outer diameter of the standard coil is 1200mm, and the outer diameter and load-bearing capacity can be increased according to the special needs of customers. | |||||

| ●Standard accessories: Floor-type induction device Four-point fine-tuning device (with dial indicator) Drag rack A-shaped material stop rack X4 pieces ●Special accessories: Leveling machine inverter Material rack power system Material rack inverter Material rack hydraulic expansion device Cylinder pressing arm Fixed material stop rack Photoelectric induction device Feeding trolley: can rise and fall, move forward and backward, and feed automatically ●Typical applications: Automatic stamping and leveling operations for electrical hardware, automotive hardware, mechanical hardware, air conditioning hardware, and kitchen and bathroom hardware. | |||||

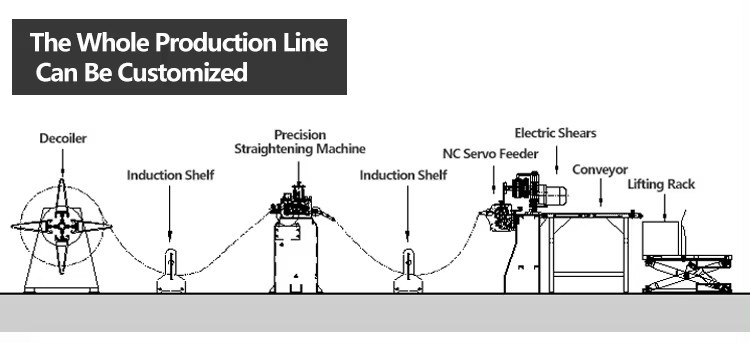

Recommended products