Guangdong Sheet straightener 3-in-1 feeder punch press good quality low price

Product description

| Product Description | |||||||||||

| Type | NCF-200 | NCF-300 | NCF-400 | NCF-500 | NCF-600 | NCF-700 | NCF-800 | NCF-1000 | NCF-1300 | NCF-1600 | |

| Width of Material (mm) | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1300 | 1600 | |

| Thickness of Material (mm) | 0.2-3.0mm | ||||||||||

| Standard Thickness (mm) Max. Feeding Thickness And Width | 0.2-1.6mm | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1300 | 1600 |

| 2.2mm | 180 | 280 | 300 | 350 | 400 | 450 | 480 | 550 | 650 | 700 | |

| 3.0mm | 80 | 100 | 1200 | 150 | 180 | 210 | 240 | 280 | 320 | 360 | |

| Feeding Length(mm) | 9999mm | ||||||||||

| The Fastest Feeding Speed M/Min | 20M/Min | ||||||||||

| Use | Sheet | ||||||||||

| Usage | Metal Sheet Strip Coil | ||||||||||

| Function | Feed Metal Sheet | ||||||||||

| If oem/odm | YES | ||||||||||

| Power Supply (V) | AC 3 Phase 220V/380V/50HZ | ||||||||||

| Feature : ◎ High precision:±0.02mm ◎ Suitable for material thickness :0.16-3.0mm. ◎ Suitable for metal parts, electron, electrical appliance, toy and auto parts continuous pressing production,straightening and feeding. ◎ Japan servo motor, PLC and other electrical parts, with little malfunction and long using time. High quality, easy maintenance. ◎ Can feed different length at the time, easy operation, safe and high stability. ◎ OEM & ODM acceptable,It can be designed and manufactured according to the customer's material properties (special-shaped materials, bright electroplated plates and various special materials). ◎ Fast speed:20m/min. ◎ Touch screen and button double control mode | |||||||||||

| A. Main configuration Adopting Japanese Yaskawa servo motor, Japanese Mitsubishi PLC programming, and can be configured with full touch screen human-machine interface. B. Performance characteristics 1. Feeding length is not limited 2. Intelligent adjustment of feeding length through human-machine interface operation, simple operation, convenient and fast adjustment. It is especially suitable for use in the case of frequent conversion of multiple varieties, which can greatly save the adjustment time required for variety conversion, and the adjustment is accurate, and there will be no bad products during trial operation. 3. Simple operation panel, equipped with key digital codes for feeding length and feeding speed, the operator can set it arbitrarily, quickly and accurately, the feeding length can be from 0.1mm - 9999.99mm; touch screen can also be selected, and operation through the touch screen is more intuitive and simpler. 4. It adopts pneumatic relaxation (accurate relaxation point), long service life and zero failure. 5. It can be converted into mechanical relaxation according to customer requirements. C. Machine structure 1. High-quality, brushless servo motor drive is used to effectively shorten the time for feeding distance adjustment and testing; 2. High-sensitivity decoder is used, feedback is accurate, and feeding accuracy is further improved; 3. Belt drive can eliminate gear clearance, with minimal wear, no noise, and no need for lubrication, which is safe and environmentally friendly; 4. The motor is built-in to avoid damage during transportation and loading and unloading. | |||||||||||

| Features of Thick Plate Servo Feeder 1. The thick plate servo feeder system controls the feeding length, the feeding length is not limited, and the feeding accuracy is higher; 2. Mechanical relaxation, simpler adjustment, sensitive response, high accuracy, and good durability; 3. Perfect combination with mechanical relaxation, high-speed stamping can be achieved; 4. Pneumatic relaxation device can be installed to meet the needs of different occasions. 5. Domestic servo system can be selected, which is more economical; 6. Standard color LCD touch screen Chinese human-machine interface, more humane operation | |||||||||||

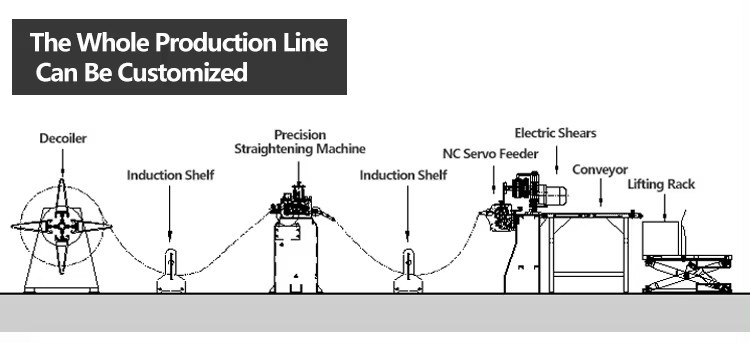

| Hydraulic Decoiler → Precision Straightener → High Speed Gantry Perforation Machine → Notching And Shearing Press →High Precision Straightener→ Tiles Flipping Machine→Bending Forming Machine | |||||||||||

Recommended products