Programmable High Low Temperature Thermal Shock Environmental Test Chamber

Product description

When selecting a Programmable High Low Temperature Thermal Shock Environmental Test Chamber, consider the following factors to ensure it meets your specific testing requirements:

Test Requirements

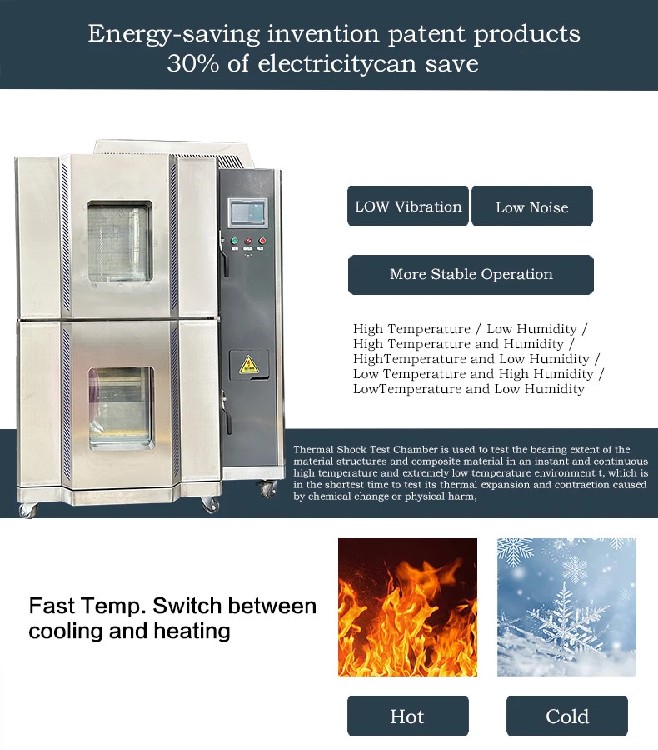

- Temperature Range: Determine the specific high and low temperatures your samples will be exposed to. The chamber should be able to provide a wide temperature range, typically from -65°C to +150°C, to simulate extreme conditions.

- Temperature Transition Speed: Assess the speed at which the chamber can transition between high and low temperatures. Faster transition times are crucial for thermal shock testing to accurately simulate rapid changes in environmental conditions.

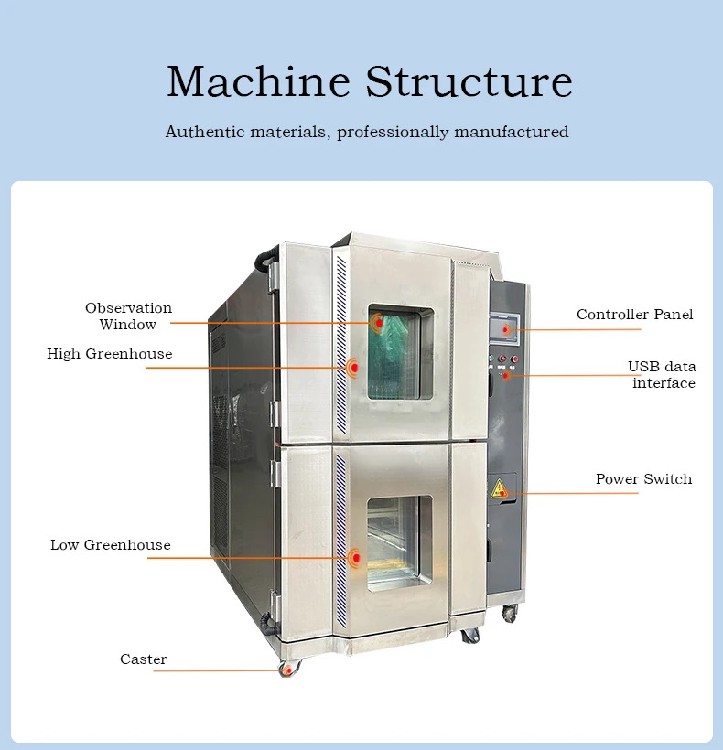

Chamber Size and Volume

- Internal Dimensions: Choose a chamber with adequate internal dimensions to accommodate your test samples comfortably. Consider the size and number of samples you need to test simultaneously.

- Sample Placement: Ensure the chamber design allows for easy placement and retrieval of samples, and that it provides sufficient space for proper air circulation around the samples.

Control Accuracy and Uniformity

- Temperature Control Precision: Evaluate the chamber's ability to maintain precise temperature levels, with a control accuracy of ±0.5°C or better, to ensure consistent and reliable test results.

- Uniformity: Assess the uniformity of temperature distribution within the chamber to ensure that all samples are exposed to the same conditions, providing accurate and repeatable test data.

Additional Features and Functionality

- Programmability: Look for chambers with programmable test cycles, allowing you to set specific temperature profiles and durations for your tests. This feature can help automate the testing process and improve efficiency.

- Data Logging and Monitoring: Consider chambers equipped with data logging capabilities and remote monitoring options. These features enable continuous monitoring and recording of test conditions, making it easier to analyze trends and identify issues during testing.

- Safety Features: Evaluate the chamber's safety features, such as alarms, cut-offs, and door safety interlocks, to ensure the protection of both the test samples and the operators.

Manufacturer Reputation and Service

- Reputation: Research the manufacturer's industry reputation, considering factors like customer reviews, product quality, and industry recognition.

- After-Sales Support: Assess the manufacturer's commitment to after-sales support, including technical assistance, warranty coverage, and availability of spare parts. Good customer support can be crucial for maintaining the chamber's performance and addressing any issues that may arise.

Cost and Budget

- Cost-Effectiveness: Consider the overall cost of the chamber, including not only the initial purchase price but also the potential costs of maintenance, energy consumption, and any necessary accessories.

- Budget Alignment: Ensure the chosen chamber aligns with your budget while meeting your testing requirements. Look for options that offer a balance between functionality and affordability.

- By carefully considering these factors, you can select a Programmable High Low Temperature Thermal Shock Environmental Test Chamber that effectively meets your specific testing needs and contributes to the success of your research or product development projects.

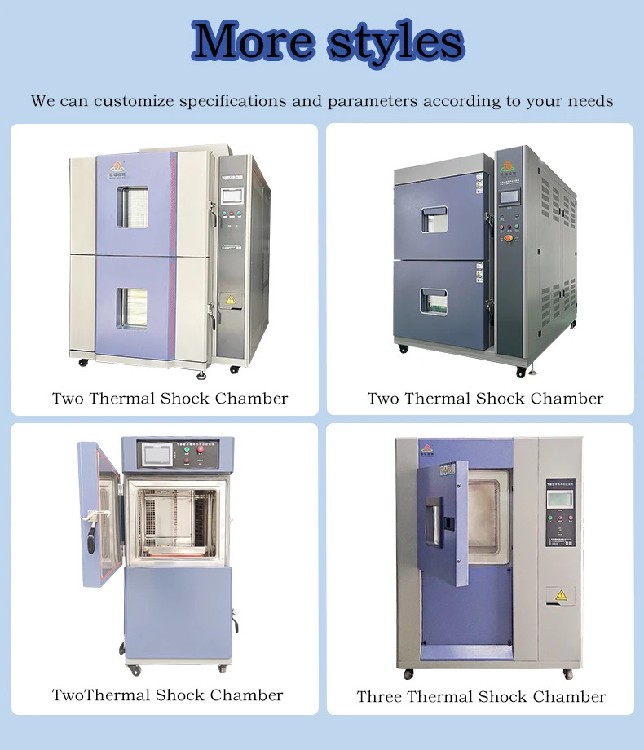

Recommended products