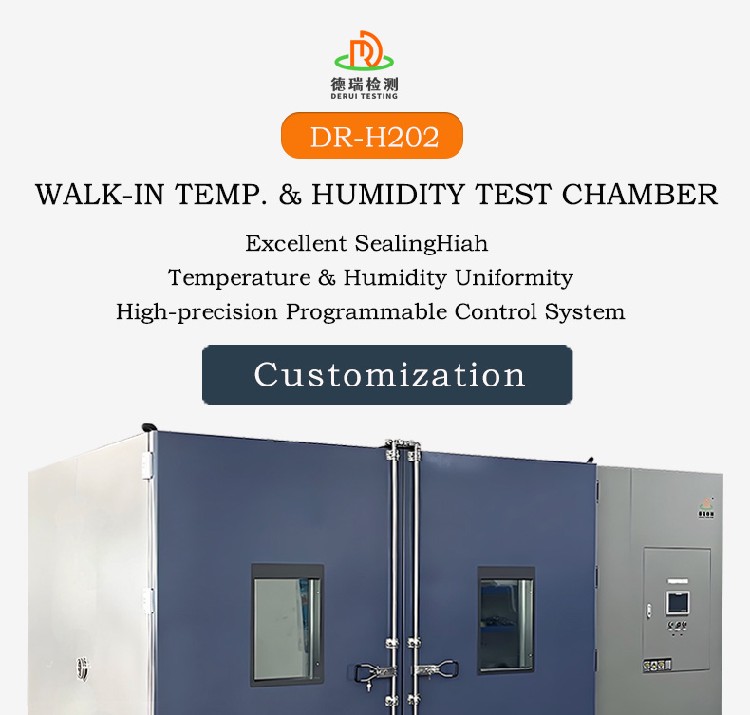

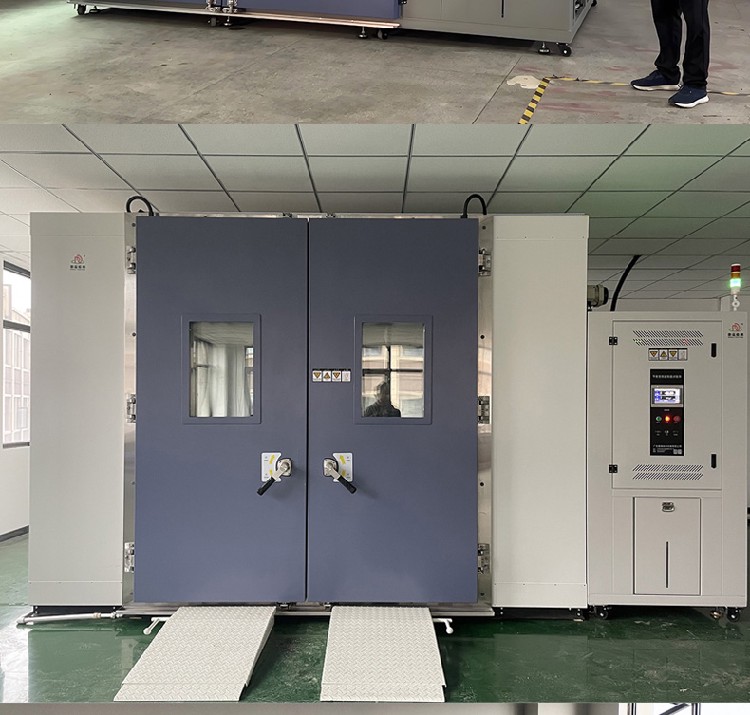

Temperature cycling walk-in high-low temperature test chamber

Product description

Temperature Cycling Walk-In High-Low Temperature Test Chamber

A Temperature Cycling Walk-In High-Low Temperature Test Chamber is a specialized environmental chamber designed to simulate extreme temperature fluctuations and cycles, often between very high and low temperatures, to test the reliability and durability of large components, materials, or systems. These chambers are primarily used in industries such as aerospace, automotive, electronics, and defense, where products need to undergo rigorous thermal cycling tests to assess their performance in real-world environmental conditions.

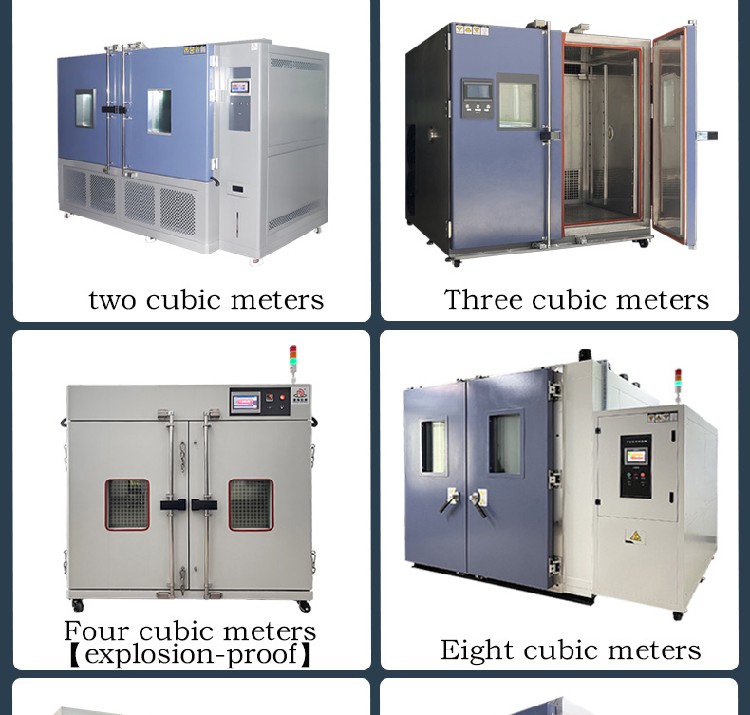

The walk-in design allows for the testing of large items, including full-scale prototypes, large assemblies, and systems, providing ample space for multiple samples or large products to undergo simultaneous testing.

Product Features

- Wide Temperature Range for Cycling:Temperature Range: Typically from -70°C to +180°C or -100°C to +250°C, allowing for precise control over both high and low temperatures. The temperature cycling process can simulate real-world conditions like rapid temperature shifts and extreme climate changes.Fast Temperature Transition: Equipped with high-performance cooling and heating systems, the chamber can achieve rapid temperature transitions, enabling the testing of products under quick cycling conditions to simulate years of environmental exposure in a short period.

- Temperature Cycling Capabilities:Rapid Cycling: The chamber is capable of rapid temperature cycling, changing temperatures from high to low (or vice versa) in a matter of minutes or hours, depending on the specified testing protocols.Programmable Test Profiles: Users can program complex temperature cycles, including temperature ramp rates, hold times, and number of cycles, to replicate the specific conditions required for a given application.Custom Cycling Profiles: The system can be customized to perform non-linear cycling, such as extended hold periods at specific temperatures or gradual ramps, simulating real-world temperature fluctuations experienced by products in the field.

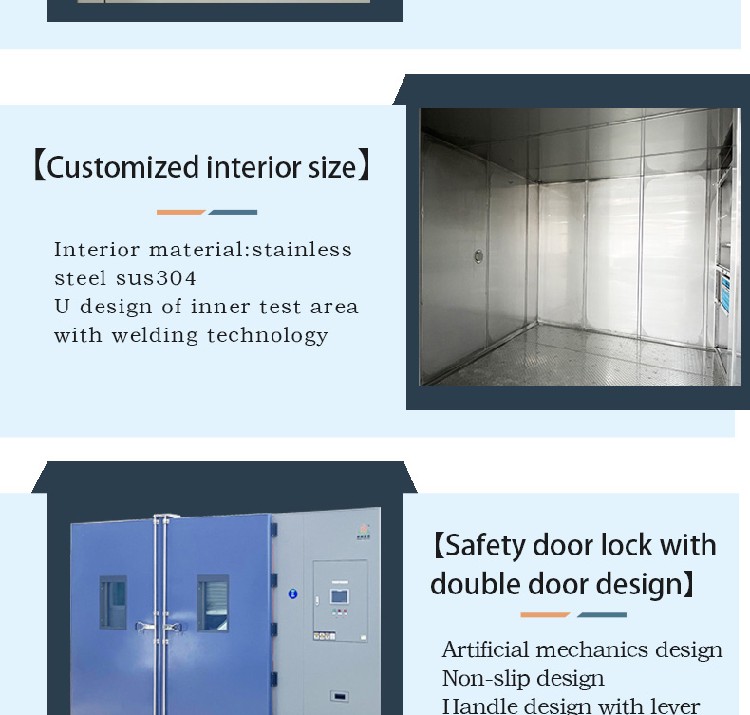

- Walk-In Design for Large Samples:Ample Testing Space: The walk-in design offers a spacious internal volume, allowing the chamber to accommodate large components such as aerospace parts, automotive test articles, heavy machinery components, or entire electrical assemblies.Flexible Rack and Shelving Options: The chamber can be customized with adjustable racks, trays, or mounting systems to securely hold and organize large test samples during cycling tests.

- High-Uniformity Temperature Distribution:Consistent Temperature Distribution: The chamber uses forced-air circulation systems, advanced air distribution technologies, and strategically placed heating and cooling elements to ensure that the temperature is evenly distributed throughout the chamber. This ensures all test samples experience identical conditions during testing, regardless of their position within the chamber.Minimal Temperature Variation: The chamber is designed to maintain low temperature gradients (typically within ±2°C), providing highly uniform conditions for accurate testing.

- Energy-Efficient Operation:High-Efficiency Cooling and Heating Systems: The chamber is built with energy-efficient compressors, heat exchangers, and variable speed fans to minimize power consumption while maintaining accurate temperature control.Insulated Construction: The walls, ceiling, and floor are lined with high-quality insulation materials that help minimize energy loss and ensure that the chamber can maintain set temperatures efficiently.Eco-friendly Refrigerants: The cooling system typically uses eco-friendly refrigerants (e.g., R-32, R-290) that have a low environmental impact, reducing the carbon footprint of the testing process.

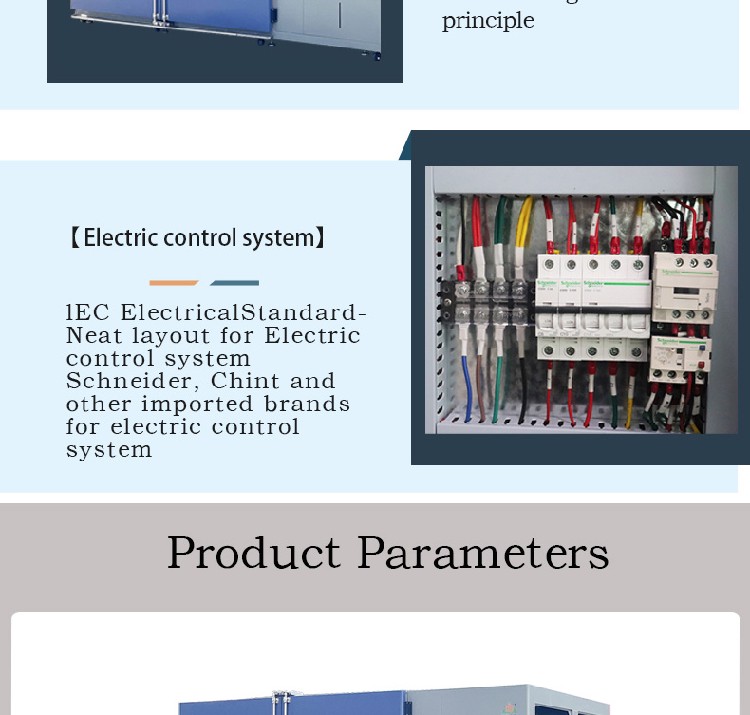

- Advanced Control and Monitoring System:Touchscreen Control Interface: The chamber features an intuitive touchscreen control panel that allows users to easily set and adjust temperature parameters, programming test profiles, and monitor the ongoing test cycle.Remote Monitoring and Control: Many chambers come equipped with remote monitoring capabilities that allow users to control and monitor the test chamber remotely, using an internet connection or dedicated software. This allows for better oversight and management of tests, especially for long-duration cycling tests.Data Logging and Reporting: Real-time data logging of temperature and cycle parameters provides detailed records of the test for analysis. Data can often be exported in formats like CSV, Excel, or through specialized reporting software.

- Safety Features:Over-Temperature Protection: Built-in over-temperature alarms and automatic shutdown features protect the test samples and the chamber from overheating during extended testing periods.Pressure Relief: The chamber includes pressure relief valves to prevent damage in case of rapid temperature fluctuations that could cause internal pressure buildup.Fire Suppression System (optional): In some cases, a fire suppression system is integrated for safety during prolonged tests in extreme conditions.

Product Characteristics

- Durability Testing:The temperature cycling chamber is ideal for testing the durability and long-term reliability of products subjected to frequent temperature changes. These tests simulate the stress caused by environmental temperature variations, such as those experienced during transportation, storage, or field use.

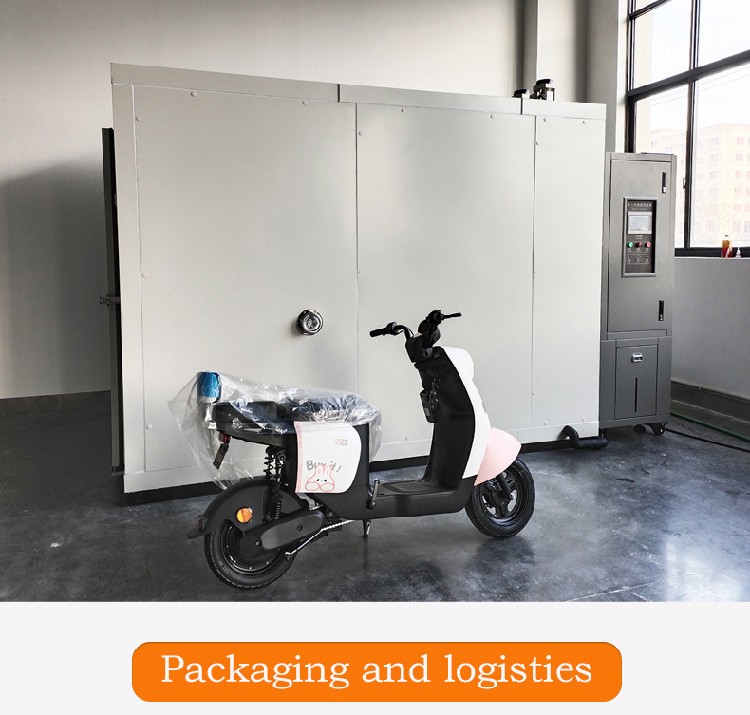

- Suitable for Large-Scale Testing:The walk-in design is well-suited for testing large, heavy, or full-scale products, including aerospace systems, automotive components, and electrical cabinets. It allows manufacturers to test their products as complete assemblies instead of individual components.

- Advanced Precision:The chamber offers high-precision temperature control with rapid transitions and even distribution, making it possible to test a range of materials, from temperature-sensitive electronic components to rugged industrial parts.

- Customization for Specific Applications:The chamber is fully customizable to meet the specific requirements of the testing application. For example, some models offer options for custom temperature cycling protocols, including complex ramps, holds, and extended testing periods.Optional features such as humidity control, altitude simulation, or vibration testing can be added to provide even more comprehensive testing environments.

- Energy Efficiency:The energy-efficient design minimizes the chamber's operating costs by reducing the amount of electricity required to maintain the desired conditions, making it a cost-effective solution for long-term use.

Usage Guidelines

- Test Preparation:Prepare test samples by ensuring that they are clean, properly mounted, and securely positioned within the chamber.For large or heavy items, ensure they are supported and fixed in place to prevent shifting during cycling.

- Programming Test Profiles:Set the test parameters such as temperature range, ramp rate, and hold times based on the specifications for the materials or components being tested.If the test involves multiple cycles, define the number of cycles, the cycle time, and the number of transitions between high and low temperatures.

- Monitoring and Adjustments:During testing, use the real-time monitoring feature to check the temperature and ensure it remains within the specified limits. If any issues arise (such as temperature deviation), the system can alert you and automatically adjust parameters.Make adjustments to the test profiles as necessary based on the testing conditions or observations from previous tests.

- Data Logging and Review:Utilize the data logging system to track temperatures, test duration, and other parameters. The logged data will help identify patterns, correlations, or potential failures, and can be used to produce test reports for documentation.

- Post-Test Evaluation:After completing the temperature cycling test, evaluate the test samples for any physical changes, material degradation, or performance degradation. Inspect for signs of thermal stress such as cracking, warping, or discoloration.Use the test data to analyze product performance and assess the effects of the temperature cycles on the product’s durability.

Installation Environment

- Room Space:The installation site should provide adequate space for both the chamber and for maintenance access. Ensure the space allows for unobstructed airflow, which is crucial for the chamber’s cooling and heating systems to function optimally.

- Power Supply:The chamber requires a stable three-phase power supply with sufficient amperage to support the high-power demands of the heating and cooling units. Check that the electrical infrastructure meets the manufacturer’s specifications.

- Ventilation:The installation area should have good ventilation to prevent heat buildup from the chamber. Make sure the exhaust air from the chamber does not directly impact nearby sensitive equipment.

- Ambient Temperature:The ambient temperature of the room should ideally be between 18°C and 25°C to ensure optimal performance and energy efficiency. Extreme ambient temperatures may affect the chamber’s ability to maintain the desired test conditions.

- Safety Considerations:Ensure that the installation site has emergency stop buttons, proper fire safety measures, and clear exit pathways for personnel.

Conclusion

The Temperature Cycling Walk-In High-Low Temperature Test Chamber is an indispensable tool for testing the durability and reliability of large-scale products or components subjected to extreme temperature fluctuations. With its customizable design, precise temperature control, and energy-efficient operation, this chamber is perfect for industries where rigorous environmental testing is necessary. The walk-in design allows for testing of full-scale products, offering flexible and spacious configurations. Through rapid cycling, advanced monitoring, and customizable test profiles, this chamber ensures that products can be thoroughly tested under real-world conditions, providing valuable insights into their long-term performance.

Recommended products