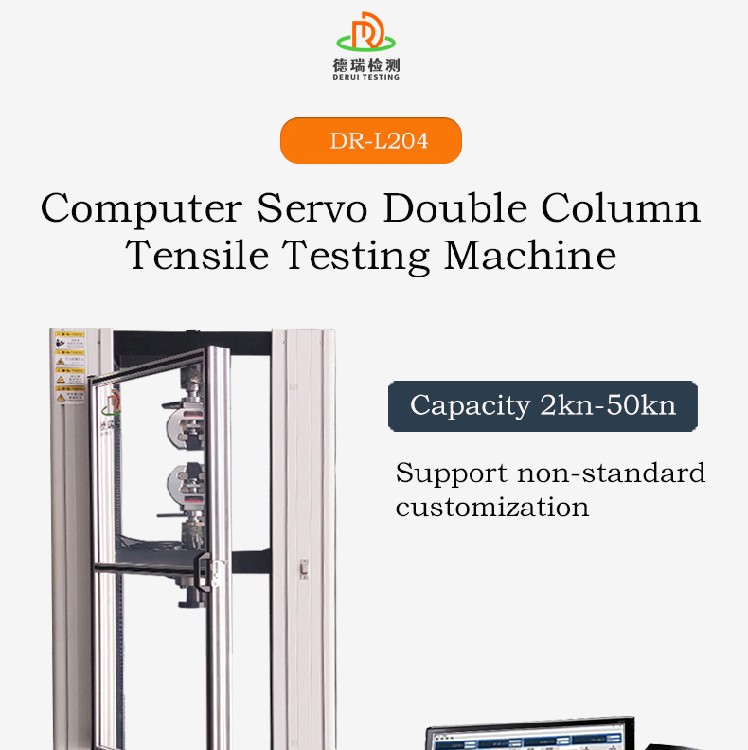

Textile fiber double-column tensile testing machine

Product description

The textile fiber double column tensile testing machine is a specialized instrument and equipment used to test the tensile properties of textile fibers.

1、 Main structure

Double column frame

Usually made of high-strength metal materials such as aluminum alloy or steel. The double column structure provides stable support, ensuring that the testing machine does not shake during the testing process and guaranteeing the accuracy of the test results.

The spacing between columns is designed reasonably to accommodate the installation of textile fiber samples of different types and sizes.

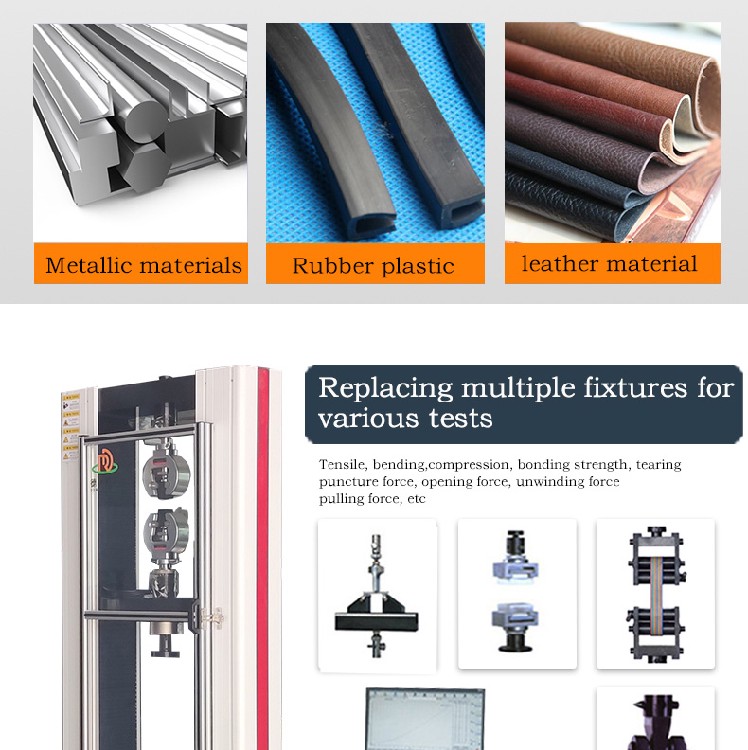

Fixture system

Including upper and lower fixtures. The material of the fixture is generally metal, and the surface may undergo special treatments such as sanding or chrome plating to increase friction and prevent the fiber sample from slipping during the stretching process.

The opening shape and size of the fixture are diverse, and can be adjusted according to the type of fiber (such as cotton fiber, hemp fiber, chemical fiber, etc.) and the specifications of the sample.

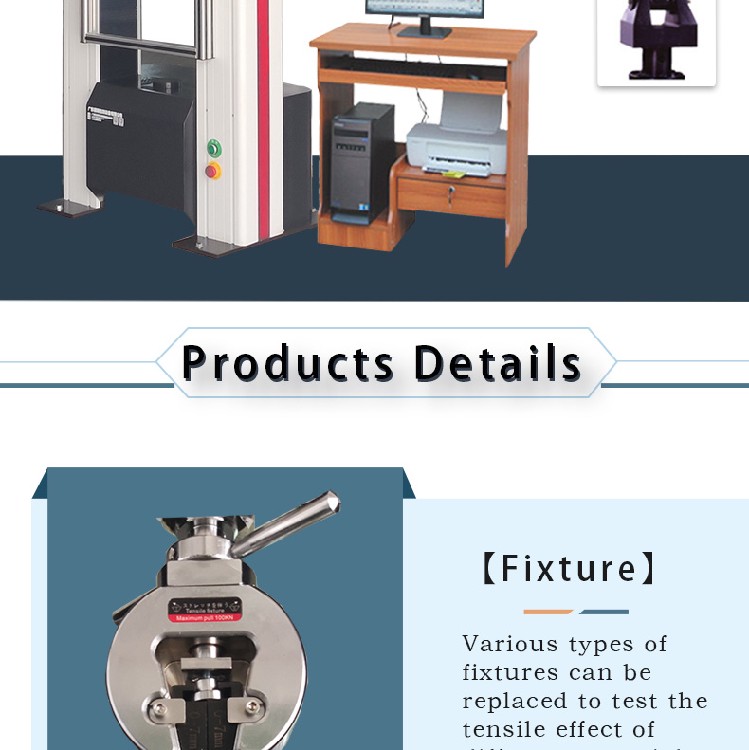

drive system

Composed of components such as motors, screws, nuts, etc. The motor provides power, and through the cooperation of the screw and nut, the rotational motion of the motor is converted into linear motion, thereby achieving the stretching of the fiber sample.

The transmission system has high precision and can accurately control the stretching speed, for example, it can be set to different speeds such as 1mm/min and 5mm/min to meet the requirements of different testing standards.

2、 Working principle

Install the sample

Fix one end of the textile fiber sample on the lower fixture, and thread the other end through the upper fixture and fix it. The length of the sample is determined according to the testing standards and the range of the equipment, generally ranging from tens of millimeters to hundreds of millimeters.

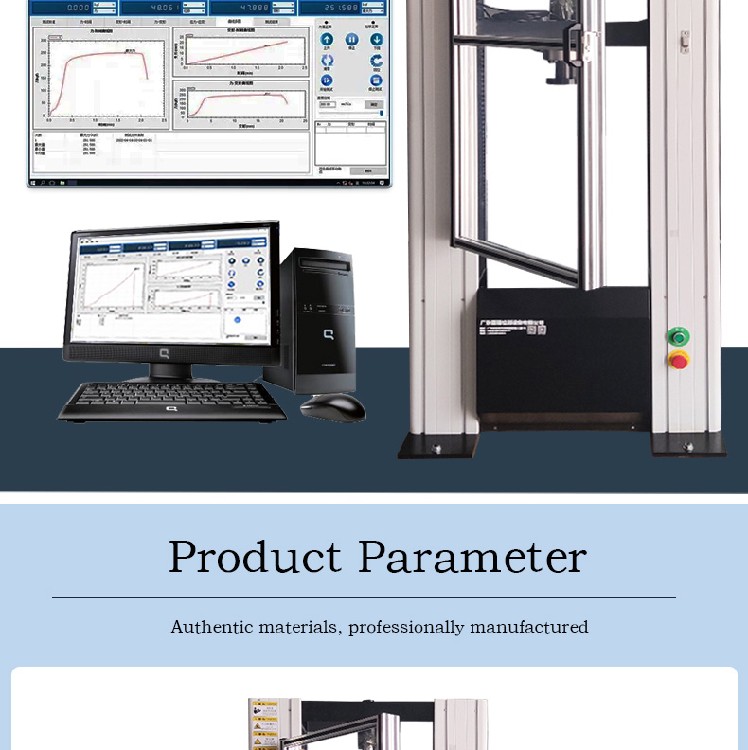

Set parameters

Set parameters such as tensile speed and tensile length (i.e. displacement at the time of sample fracture) in the control system of the testing machine.

Start testing

Start the motor, and the transmission system drives the upper fixture to move upward, applying tension to the fiber sample. During the stretching process, the testing machine measures and records the tension value and the elongation of the specimen in real time.

When the fiber sample reaches its fracture strength, the tensile value will suddenly decrease. At this time, the testing machine records important data such as the maximum tensile value and elongation at break.

3、 Application Fields

Textile industry

Used to evaluate the quality of textile fibers. For example, in cotton procurement, the strength of cotton fibers can be tested using a double column tensile testing machine to determine the quality grade of cotton.

Assist textile enterprises in optimizing production processes. If the performance of a certain fiber is found to be unsatisfactory in tensile testing, adjustments can be made to spinning, weaving, and other processes.

Material research

Researchers can use this testing machine to study the properties of new textile fibers, such as nanofibers and bio based fibers. Explore the application potential of new fibers through comparative testing with other traditional fibers.

Product quality inspection

In the production process of textile products, random inspections are conducted on finished or semi-finished products (such as yarns, fabrics, etc.) to ensure that the products meet relevant quality standards.

Recommended products